Posted 29 July 2021,

In my ongoing quest to convert my MakerGear M3-ID printer from a nice bench decorative piece into a real functioning printer.

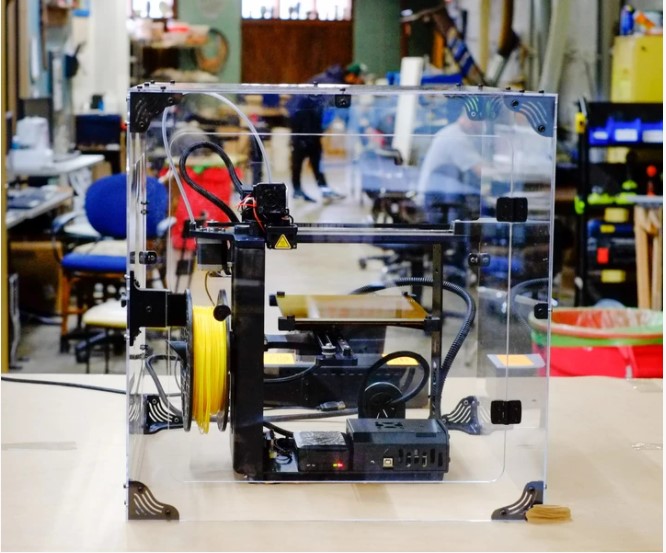

Recently I have been having real problems with using dissolvable filaments with my MakerGear M3-ID dual-extruder 3D printer. I couldn’t get either the PVA (water soluble) or HIPS (Limonene soluble) filaments to stick worth a damn to the BuildTak surface. In the process of troubleshooting the problems, I discovered that the M3-ID has real trouble getting the print bed temperature above 100C – at least in my nicely air-conditioned lab spaces. So, I went on the hunt for a decent enclosure, and found this 3D Upfitters model.

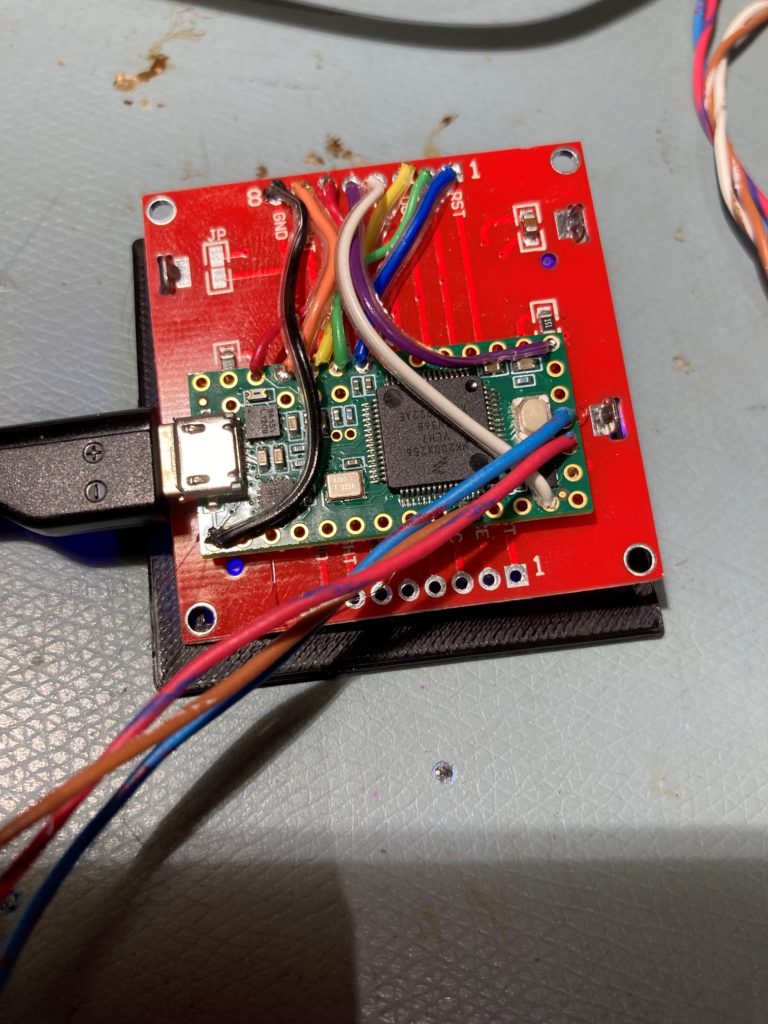

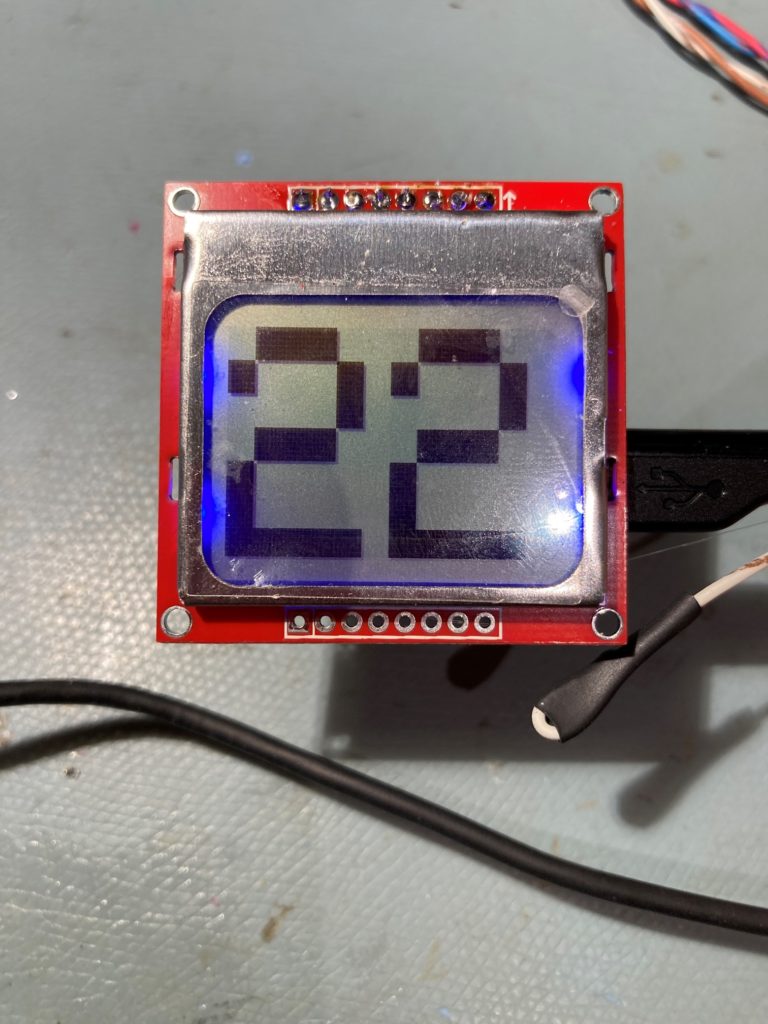

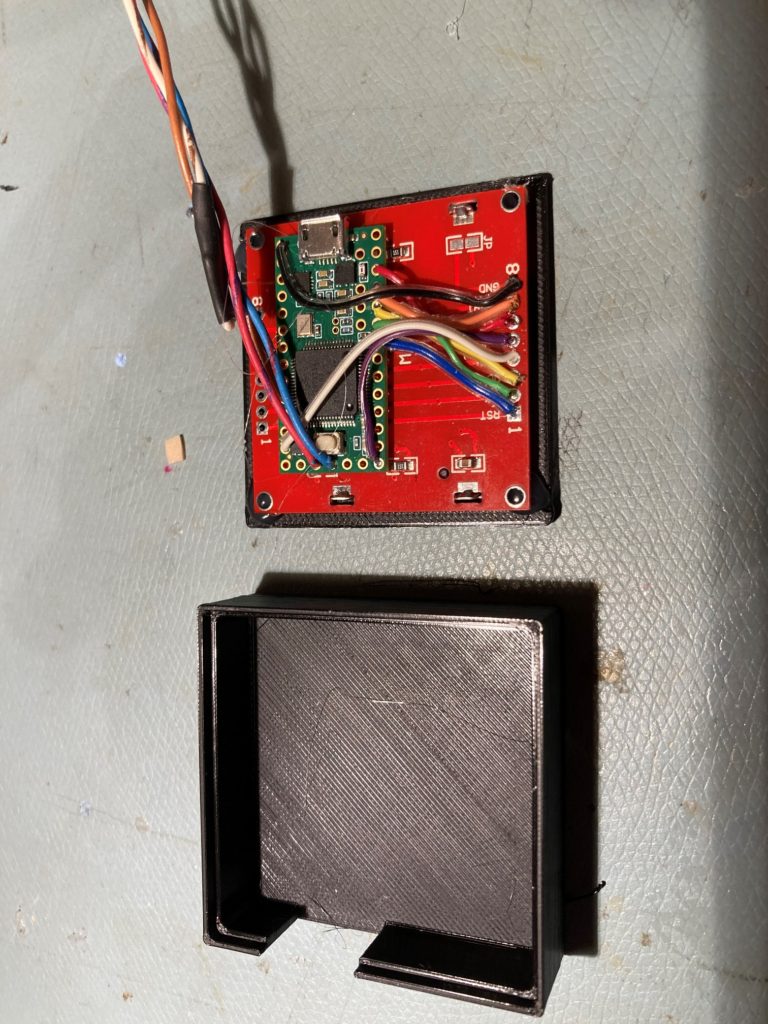

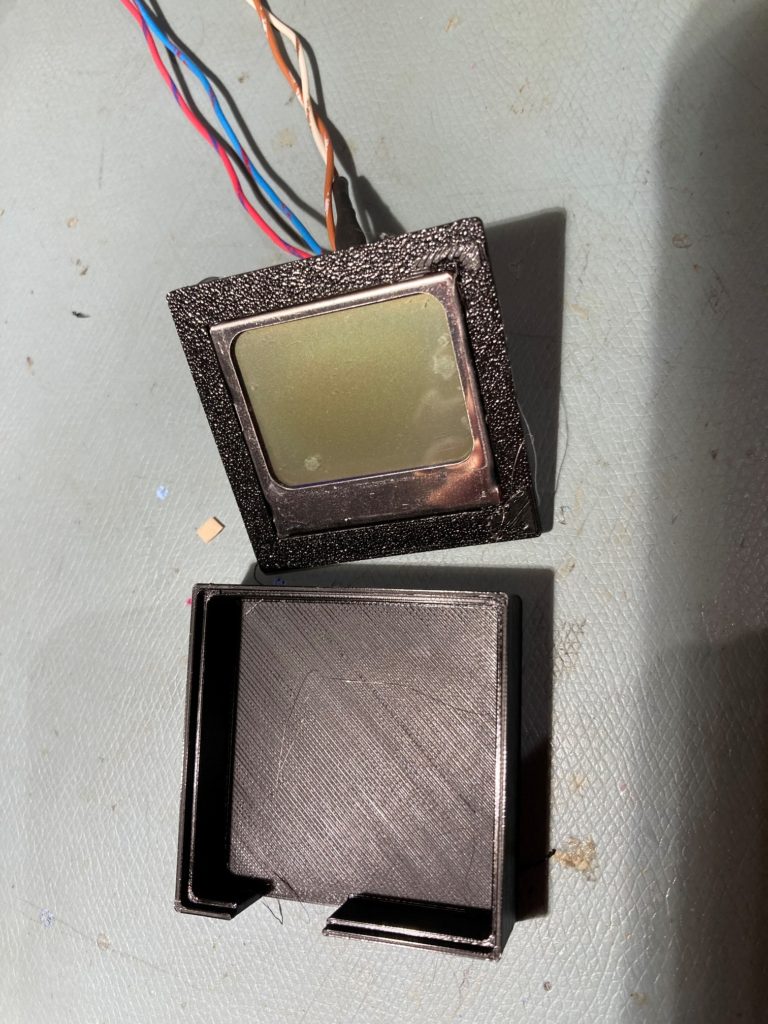

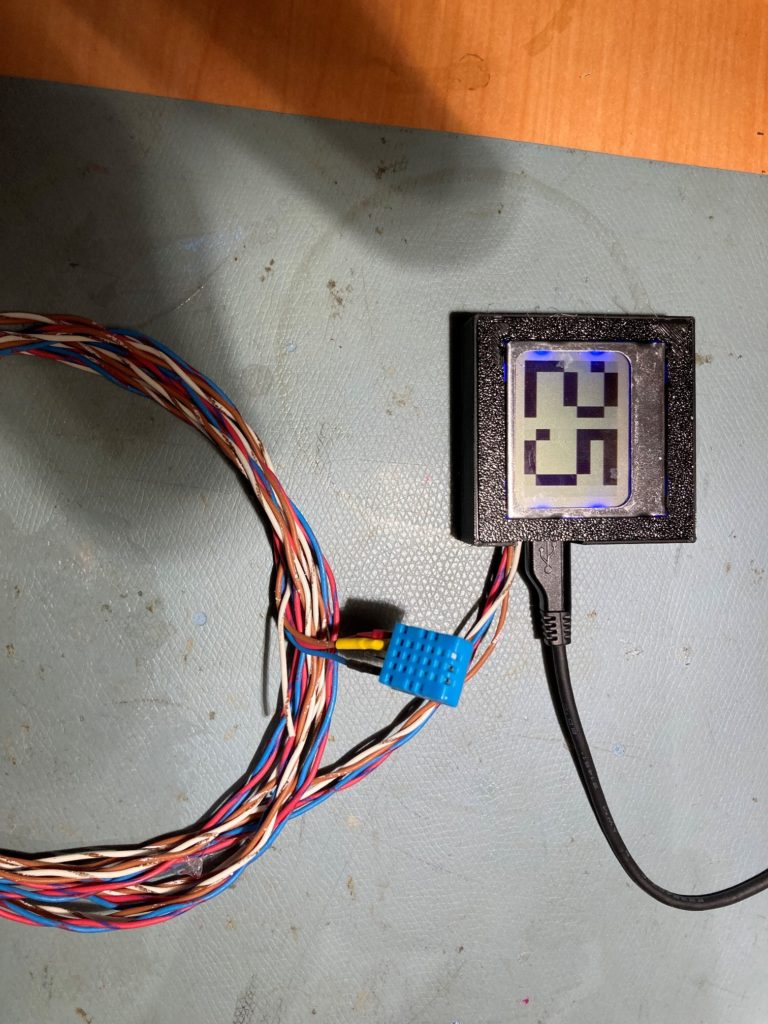

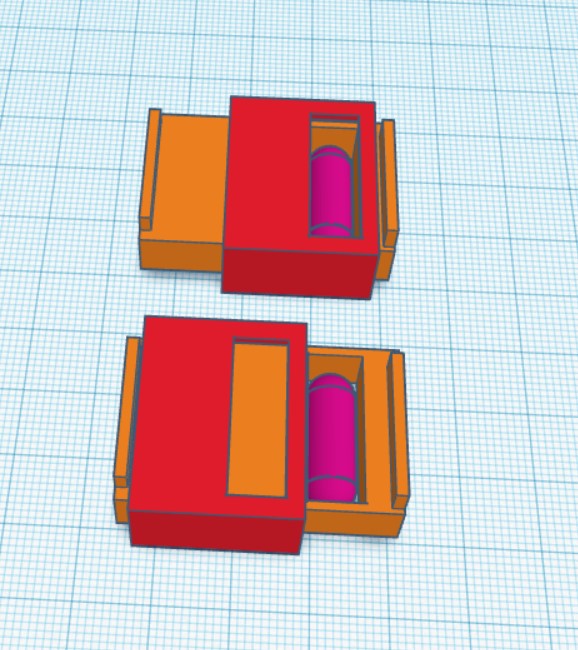

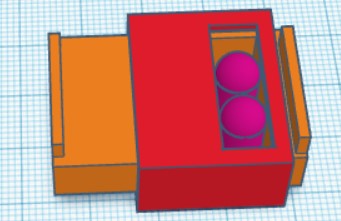

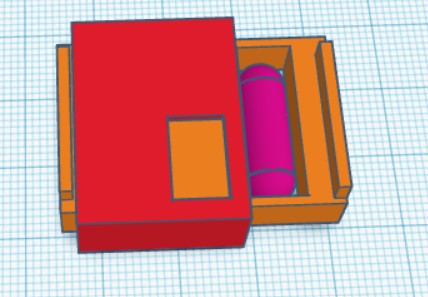

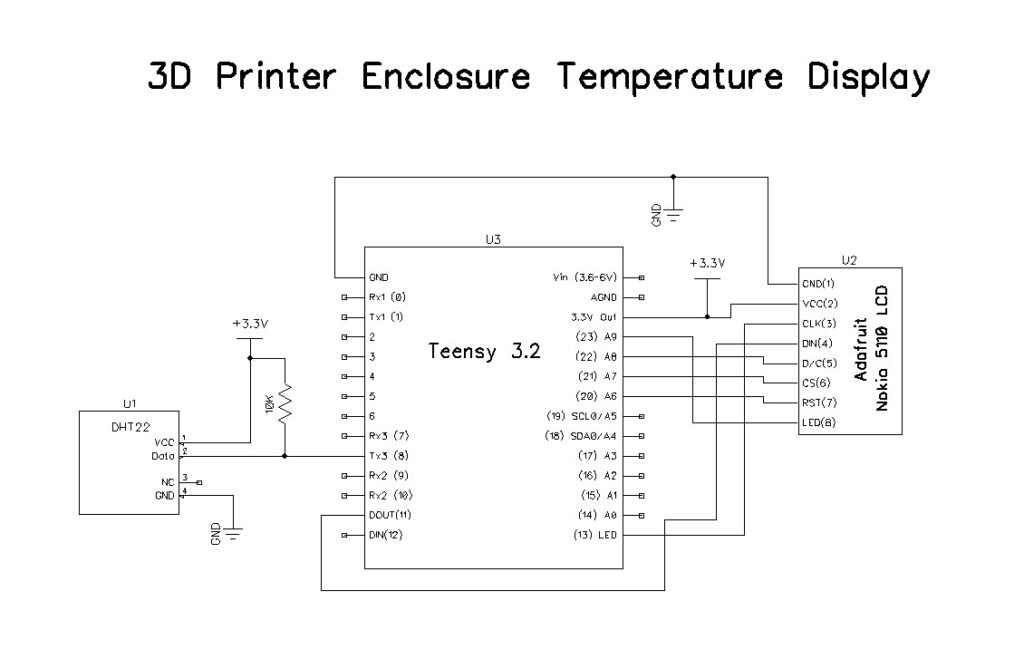

The dimensions shown for the enclosure look like they would work for my setup, so I ordered one – we’ll see. In the meantime I started thinking that I might like to control (or at least monitor) the internal temperature, especially the ambient temperature at the location of the Octoprint module and control electronics. My worry is that at high bed temperatures, the ambient temps might get worryingly close to the max temps for the control electronics. 3D Upfitters does offer a temperature readout, but I was pretty sure it wouldn’t accurately represent the ambient temps around the electronics, so I decided I would modify an earlier project to create a custom temperature probe, using the venerable Nokia 5110 LCD display, a DHT11 temperature/humidity sensor, and a Teensy 3.2.

I decided to use the Teensy 3.2 micro-controller rather than an Arduino UNO to avoid the issue with 5/3.3V level conversion and because I’ve used this item several times before in other projects. I’m sure there are cheaper alternatives, but this is what I had available, and they are rock-solid products. Here’s the schematic:

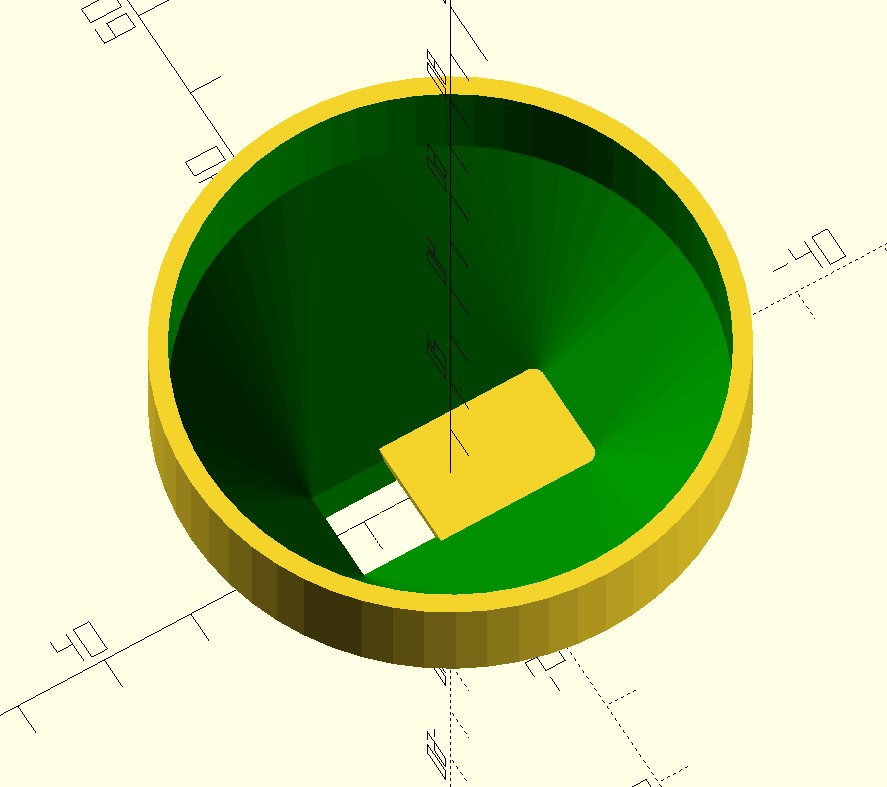

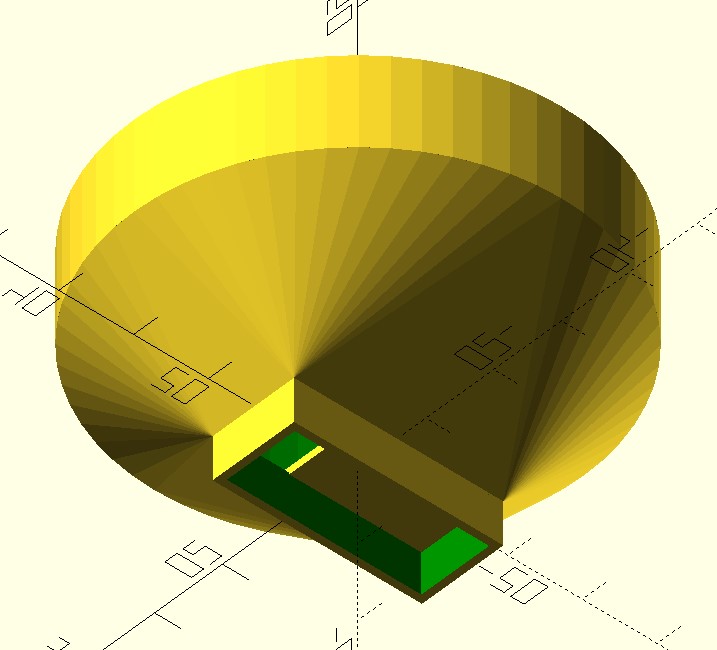

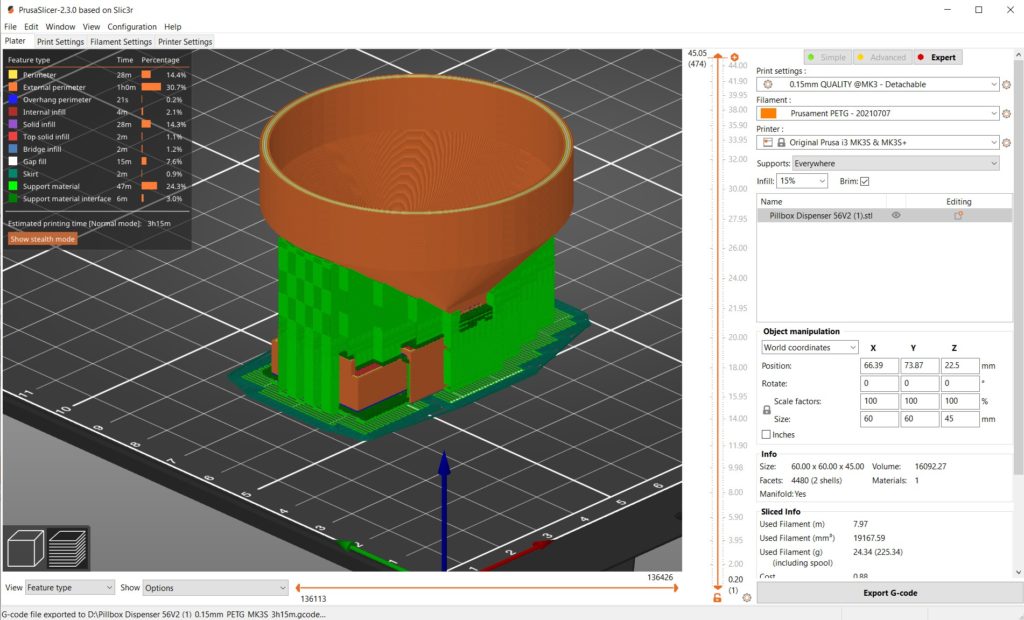

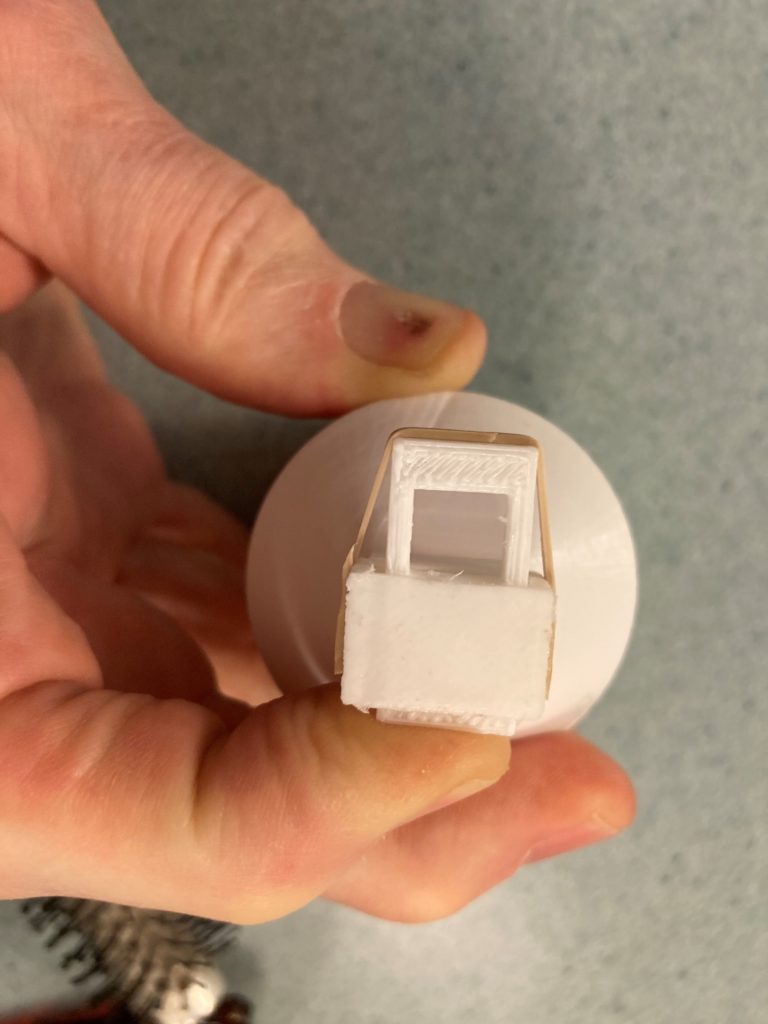

And here are some photos:

And here is the code that interfaces to the sensor and drives the display:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239 240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255 256 257 258 259 260 261 262 263 264 265 266 267 268 269 270 271 272 273 274 275 276 277 278 279 280 281 282 283 284 285 286 287 288 289 290 291 292 293 294 295 296 297 298 299 300 301 302 303 304 305 306 307 308 309 310 311 312 313 314 315 316 317 318 319 320 321 322 323 324 325 326 327 328 329 330 331 332 333 334 335 336 337 338 339 340 341 342 343 344 345 346 347 348 349 350 351 352 353 354 355 356 357 358 359 360 361 362 363 364 365 366 367 368 369 370 371 372 373 374 375 376 377 378 379 380 381 382 383 384 385 386 387 388 389 390 391 392 393 394 395 396 397 398 399 400 401 402 403 404 405 406 407 408 409 410 411 412 413 414 415 416 417 418 419 420 421 422 423 424 425 426 427 428 429 430 431 432 433 434 435 436 437 438 439 440 441 442 443 444 445 446 447 448 449 450 451 452 453 454 455 456 457 458 459 460 461 462 463 464 465 466 467 468 469 470 471 472 473 474 475 476 477 478 479 480 481 482 483 484 485 486 487 488 489 490 491 492 493 494 495 496 497 498 499 500 501 502 503 504 505 506 507 508 509 510 511 512 513 514 515 516 517 518 519 520 521 522 523 524 525 526 527 528 529 530 531 532 533 534 535 536 537 538 539 540 541 542 543 544 545 546 547 548 549 550 551 552 553 554 555 556 557 558 559 560 561 562 563 564 565 566 567 568 569 570 571 572 573 574 575 576 577 578 579 580 581 582 583 584 585 586 587 588 589 590 591 592 593 594 595 596 597 598 599 600 601 602 603 604 605 606 607 608 609 610 611 612 613 614 615 616 617 618 619 620 621 622 623 624 625 626 627 628 629 630 631 632 633 634 635 636 637 638 639 640 641 642 643 644 645 646 647 648 649 650 651 652 653 654 655 656 657 658 659 660 661 662 663 664 665 666 667 668 669 670 671 672 673 674 675 676 677 678 679 680 681 682 683 684 685 686 687 688 689 690 691 692 693 694 695 696 697 698 699 700 701 702 703 704 705 706 707 708 709 710 711 712 713 714 715 716 717 718 719 720 721 722 723 724 725 726 727 728 729 730 731 732 733 734 735 736 737 738 739 740 741 742 743 744 745 746 747 748 749 750 751 752 753 754 755 756 757 758 759 760 761 762 763 764 765 766 767 768 769 770 771 772 773 774 775 776 777 778 779 780 781 782 783 784 785 786 787 788 789 790 791 792 793 794 795 796 797 798 799 800 801 802 803 804 805 806 807 808 809 810 811 812 813 814 815 816 817 818 819 820 821 822 823 824 825 826 827 828 829 830 831 832 833 834 835 836 837 838 839 840 841 842 843 844 845 846 847 848 849 850 851 852 853 854 855 856 857 858 859 860 861 862 863 864 865 866 867 868 869 870 871 872 873 874 875 876 877 878 879 880 881 882 883 884 885 886 887 888 889 890 891 892 893 894 895 896 897 898 899 900 901 902 903 904 905 906 907 908 909 910 911 912 913 914 915 916 917 918 919 920 921 922 923 924 925 926 927 928 929 930 931 932 933 934 935 936 937 938 939 940 941 942 943 944 945 946 947 948 949 950 951 952 953 954 955 956 957 958 959 960 961 962 963 964 965 966 967 968 969 970 971 972 973 974 975 976 977 978 979 980 981 982 983 984 985 986 987 988 989 990 991 992 993 994 995 996 997 998 999 1000 1001 1002 1003 1004 1005 1006 1007 1008 1009 1010 1011 1012 1013 1014 1015 1016 1017 1018 1019 1020 1021 1022 1023 1024 1025 1026 1027 1028 1029 1030 1031 1032 1033 1034 1035 1036 1037 1038 1039 1040 1041 1042 1043 1044 1045 1046 1047 1048 1049 1050 1051 1052 1053 1054 1055 1056 1057 1058 1059 1060 1061 1062 1063 1064 1065 1066 1067 1068 1069 1070 1071 1072 1073 1074 1075 1076 1077 1078 1079 1080 1081 1082 1083 1084 1085 1086 1087 1088 1089 1090 1091 1092 1093 1094 1095 1096 1097 1098 1099 1100 1101 1102 1103 1104 1105 1106 1107 1108 1109 1110 1111 1112 1113 1114 1115 1116 1117 1118 1119 1120 1121 1122 1123 1124 1125 1126 1127 1128 1129 1130 1131 1132 1133 1134 1135 1136 1137 1138 1139 1140 1141 1142 1143 1144 1145 1146 1147 1148 1149 1150 1151 1152 1153 1154 1155 1156 1157 1158 1159 1160 1161 1162 1163 1164 1165 1166 1167 1168 1169 1170 1171 1172 1173 1174 1175 1176 1177 1178 1179 1180 1181 1182 1183 1184 1185 1186 1187 1188 1189 1190 1191 1192 1193 1194 1195 1196 1197 1198 1199 1200 1201 1202 1203 1204 1205 1206 1207 1208 1209 1210 1211 1212 1213 1214 1215 1216 1217 1218 1219 1220 1221 1222 1223 1224 1225 1226 1227 1228 1229 1230 1231 1232 1233 1234 1235 1236 1237 1238 1239 1240 1241 1242 1243 1244 1245 1246 1247 1248 1249 1250 1251 1252 1253 1254 1255 1256 1257 1258 1259 1260 1261 1262 1263 1264 1265 1266 1267 1268 1269 1270 1271 1272 1273 1274 1275 1276 1277 1278 1279 1280 1281 1282 1283 1284 1285 1286 1287 1288 1289 1290 1291 1292 1293 1294 1295 1296 1297 1298 1299 1300 1301 1302 1303 1304 1305 1306 1307 1308 1309 1310 1311 1312 1313 1314 1315 1316 1317 1318 1319 1320 1321 1322 1323 1324 1325 1326 1327 1328 1329 1330 1331 1332 1333 1334 1335 1336 1337 1338 1339 1340 1341 1342 1343 1344 1345 1346 1347 1348 1349 1350 1351 1352 1353 1354 1355 1356 1357 1358 1359 1360 1361 1362 1363 1364 1365 1366 1367 1368 1369 1370 1371 1372 1373 1374 1375 1376 1377 1378 1379 1380 1381 1382 1383 1384 1385 1386 1387 1388 1389 1390 1391 1392 1393 1394 1395 1396 1397 1398 1399 1400 1401 1402 1403 1404 1405 1406 1407 1408 1409 1410 1411 1412 1413 1414 1415 1416 1417 1418 1419 1420 1421 1422 1423 1424 1425 1426 1427 1428 1429 1430 1431 1432 1433 1434 1435 1436 1437 1438 1439 1440 1441 1442 1443 1444 1445 1446 1447 1448 1449 1450 1451 1452 1453 1454 1455 1456 1457 1458 1459 1460 1461 1462 1463 1464 1465 1466 1467 1468 1469 1470 1471 1472 1473 1474 1475 1476 1477 1478 1479 1480 1481 1482 1483 1484 1485 1486 1487 1488 1489 1490 1491 1492 1493 1494 1495 1496 1497 1498 1499 1500 1501 1502 1503 1504 1505 1506 1507 1508 1509 1510 1511 1512 1513 1514 1515 1516 1517 1518 1519 1520 1521 1522 1523 1524 1525 1526 1527 1528 1529 1530 1531 1532 1533 1534 1535 1536 1537 1538 1539 1540 1541 1542 1543 1544 1545 1546 1547 1548 1549 1550 1551 1552 1553 1554 1555 1556 1557 1558 1559 1560 1561 1562 1563 1564 1565 1566 1567 1568 1569 1570 1571 1572 1573 1574 1575 1576 1577 1578 1579 1580 1581 1582 1583 1584 1585 1586 1587 1588 1589 1590 1591 1592 1593 1594 1595 1596 1597 1598 1599 1600 1601 1602 1603 1604 1605 1606 1607 1608 1609 1610 1611 1612 1613 1614 1615 1616 1617 1618 1619 1620 1621 1622 1623 1624 1625 1626 1627 1628 1629 1630 1631 1632 1633 1634 1635 1636 1637 1638 1639 1640 1641 1642 1643 1644 1645 1646 1647 1648 1649 1650 1651 1652 1653 1654 1655 1656 1657 1658 1659 1660 1661 1662 1663 1664 1665 1666 1667 1668 1669 1670 1671 1672 1673 1674 1675 1676 1677 1678 1679 1680 1681 1682 1683 1684 1685 1686 1687 1688 1689 1690 1691 1692 1693 1694 1695 1696 1697 1698 1699 1700 1701 1702 1703 1704 1705 1706 1707 1708 1709 1710 1711 1712 1713 1714 1715 1716 1717 1718 1719 1720 1721 1722 1723 1724 1725 1726 1727 1728 1729 1730 1731 1732 1733 1734 1735 1736 1737 1738 1739 1740 1741 1742 1743 1744 1745 1746 1747 1748 1749 1750 1751 1752 1753 1754 1755 1756 1757 1758 1759 1760 1761 1762 1763 1764 1765 1766 1767 1768 1769 1770 1771 1772 1773 1774 1775 1776 1777 1778 1779 1780 1781 1782 1783 1784 1785 1786 1787 1788 1789 1790 1791 1792 1793 1794 1795 1796 1797 1798 1799 1800 1801 1802 1803 1804 1805 1806 1807 1808 1809 1810 1811 1812 1813 1814 1815 1816 1817 1818 1819 1820 1821 1822 1823 1824 1825 1826 1827 1828 1829 1830 1831 1832 1833 1834 1835 1836 1837 1838 1839 1840 1841 1842 1843 1844 1845 1846 1847 1848 1849 1850 1851 1852 1853 1854 1855 1856 1857 1858 1859 1860 1861 1862 1863 1864 1865 1866 1867 1868 1869 1870 1871 1872 1873 1874 1875 1876 1877 1878 1879 1880 1881 1882 1883 1884 1885 1886 1887 1888 1889 1890 1891 1892 1893 1894 1895 1896 1897 1898 1899 1900 1901 1902 1903 1904 1905 1906 1907 1908 1909 1910 1911 1912 1913 1914 1915 1916 1917 1918 1919 1920 1921 1922 1923 1924 1925 1926 1927 1928 1929 1930 1931 1932 1933 1934 1935 1936 1937 1938 1939 1940 1941 1942 1943 1944 1945 1946 1947 1948 1949 1950 1951 1952 1953 1954 1955 1956 1957 1958 1959 1960 1961 1962 1963 1964 1965 1966 1967 1968 1969 1970 1971 1972 1973 1974 1975 1976 1977 1978 1979 1980 1981 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 2031 2032 2033 2034 2035 2036 |

/* This is the core graphics library for all our displays, providing a common set of graphics primitives (points, lines, circles, etc.). It needs to be paired with a hardware-specific library for each display device we carry (to handle the lower-level functions). Adafruit invests time and resources providing this open source code, please support Adafruit & open-source hardware by purchasing products from Adafruit! Copyright (c) 2013 Adafruit Industries. All rights reserved. Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are met: - Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer. - Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in the documentation and/or other materials provided with the distribution. THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. */ #include "Adafruit_GFX.h" #include "glcdfont.c" #ifdef __AVR__ #include <avr/pgmspace.h> #elif defined(ESP8266) || defined(ESP32) #include <pgmspace.h> #endif // Many (but maybe not all) non-AVR board installs define macros // for compatibility with existing PROGMEM-reading AVR code. // Do our own checks and defines here for good measure... #ifndef pgm_read_byte #define pgm_read_byte(addr) (*(const unsigned char *)(addr)) #endif #ifndef pgm_read_word #define pgm_read_word(addr) (*(const unsigned short *)(addr)) #endif #ifndef pgm_read_dword #define pgm_read_dword(addr) (*(const unsigned long *)(addr)) #endif // Pointers are a peculiar case...typically 16-bit on AVR boards, // 32 bits elsewhere. Try to accommodate both... #if !defined(__INT_MAX__) || (__INT_MAX__ > 0xFFFF) #define pgm_read_pointer(addr) ((void *)pgm_read_dword(addr)) #else #define pgm_read_pointer(addr) ((void *)pgm_read_word(addr)) #endif inline GFXglyph *pgm_read_glyph_ptr(const GFXfont *gfxFont, uint8_t c) { #ifdef __AVR__ return &(((GFXglyph *)pgm_read_pointer(&gfxFont->glyph))[c]); #else // expression in __AVR__ section may generate "dereferencing type-punned // pointer will break strict-aliasing rules" warning In fact, on other // platforms (such as STM32) there is no need to do this pointer magic as // program memory may be read in a usual way So expression may be simplified return gfxFont->glyph + c; #endif //__AVR__ } inline uint8_t *pgm_read_bitmap_ptr(const GFXfont *gfxFont) { #ifdef __AVR__ return (uint8_t *)pgm_read_pointer(&gfxFont->bitmap); #else // expression in __AVR__ section generates "dereferencing type-punned pointer // will break strict-aliasing rules" warning In fact, on other platforms (such // as STM32) there is no need to do this pointer magic as program memory may // be read in a usual way So expression may be simplified return gfxFont->bitmap; #endif //__AVR__ } #ifndef min #define min(a, b) (((a) < (b)) ? (a) : (b)) #endif #ifndef _swap_int16_t #define _swap_int16_t(a, b) \ { \ int16_t t = a; \ a = b; \ b = t; \ } #endif /**************************************************************************/ /*! @brief Instatiate a GFX context for graphics! Can only be done by a superclass @param w Display width, in pixels @param h Display height, in pixels */ /**************************************************************************/ Adafruit_GFX::Adafruit_GFX(int16_t w, int16_t h) : WIDTH(w), HEIGHT(h) { _width = WIDTH; _height = HEIGHT; rotation = 0; cursor_y = cursor_x = 0; textsize_x = textsize_y = 1; textcolor = textbgcolor = 0xFFFF; wrap = true; _cp437 = false; gfxFont = NULL; } /**************************************************************************/ /*! @brief Write a line. Bresenham's algorithm - thx wikpedia @param x0 Start point x coordinate @param y0 Start point y coordinate @param x1 End point x coordinate @param y1 End point y coordinate @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::writeLine(int16_t x0, int16_t y0, int16_t x1, int16_t y1, uint16_t color) { #if defined(ESP8266) yield(); #endif int16_t steep = abs(y1 - y0) > abs(x1 - x0); if (steep) { _swap_int16_t(x0, y0); _swap_int16_t(x1, y1); } if (x0 > x1) { _swap_int16_t(x0, x1); _swap_int16_t(y0, y1); } int16_t dx, dy; dx = x1 - x0; dy = abs(y1 - y0); int16_t err = dx / 2; int16_t ystep; if (y0 < y1) { ystep = 1; } else { ystep = -1; } for (; x0 <= x1; x0++) { if (steep) { writePixel(y0, x0, color); } else { writePixel(x0, y0, color); } err -= dy; if (err < 0) { y0 += ystep; err += dx; } } } /**************************************************************************/ /*! @brief Start a display-writing routine, overwrite in subclasses. */ /**************************************************************************/ void Adafruit_GFX::startWrite() {} /**************************************************************************/ /*! @brief Write a pixel, overwrite in subclasses if startWrite is defined! @param x x coordinate @param y y coordinate @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::writePixel(int16_t x, int16_t y, uint16_t color) { drawPixel(x, y, color); } /**************************************************************************/ /*! @brief Write a perfectly vertical line, overwrite in subclasses if startWrite is defined! @param x Top-most x coordinate @param y Top-most y coordinate @param h Height in pixels @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::writeFastVLine(int16_t x, int16_t y, int16_t h, uint16_t color) { // Overwrite in subclasses if startWrite is defined! // Can be just writeLine(x, y, x, y+h-1, color); // or writeFillRect(x, y, 1, h, color); drawFastVLine(x, y, h, color); } /**************************************************************************/ /*! @brief Write a perfectly horizontal line, overwrite in subclasses if startWrite is defined! @param x Left-most x coordinate @param y Left-most y coordinate @param w Width in pixels @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::writeFastHLine(int16_t x, int16_t y, int16_t w, uint16_t color) { // Overwrite in subclasses if startWrite is defined! // Example: writeLine(x, y, x+w-1, y, color); // or writeFillRect(x, y, w, 1, color); drawFastHLine(x, y, w, color); } /**************************************************************************/ /*! @brief Write a rectangle completely with one color, overwrite in subclasses if startWrite is defined! @param x Top left corner x coordinate @param y Top left corner y coordinate @param w Width in pixels @param h Height in pixels @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::writeFillRect(int16_t x, int16_t y, int16_t w, int16_t h, uint16_t color) { // Overwrite in subclasses if desired! fillRect(x, y, w, h, color); } /**************************************************************************/ /*! @brief End a display-writing routine, overwrite in subclasses if startWrite is defined! */ /**************************************************************************/ void Adafruit_GFX::endWrite() {} /**************************************************************************/ /*! @brief Draw a perfectly vertical line (this is often optimized in a subclass!) @param x Top-most x coordinate @param y Top-most y coordinate @param h Height in pixels @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::drawFastVLine(int16_t x, int16_t y, int16_t h, uint16_t color) { startWrite(); writeLine(x, y, x, y + h - 1, color); endWrite(); } /**************************************************************************/ /*! @brief Draw a perfectly horizontal line (this is often optimized in a subclass!) @param x Left-most x coordinate @param y Left-most y coordinate @param w Width in pixels @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::drawFastHLine(int16_t x, int16_t y, int16_t w, uint16_t color) { startWrite(); writeLine(x, y, x + w - 1, y, color); endWrite(); } /**************************************************************************/ /*! @brief Fill a rectangle completely with one color. Update in subclasses if desired! @param x Top left corner x coordinate @param y Top left corner y coordinate @param w Width in pixels @param h Height in pixels @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::fillRect(int16_t x, int16_t y, int16_t w, int16_t h, uint16_t color) { startWrite(); for (int16_t i = x; i < x + w; i++) { writeFastVLine(i, y, h, color); } endWrite(); } /**************************************************************************/ /*! @brief Fill the screen completely with one color. Update in subclasses if desired! @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::fillScreen(uint16_t color) { fillRect(0, 0, _width, _height, color); } /**************************************************************************/ /*! @brief Draw a line @param x0 Start point x coordinate @param y0 Start point y coordinate @param x1 End point x coordinate @param y1 End point y coordinate @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawLine(int16_t x0, int16_t y0, int16_t x1, int16_t y1, uint16_t color) { // Update in subclasses if desired! if (x0 == x1) { if (y0 > y1) _swap_int16_t(y0, y1); drawFastVLine(x0, y0, y1 - y0 + 1, color); } else if (y0 == y1) { if (x0 > x1) _swap_int16_t(x0, x1); drawFastHLine(x0, y0, x1 - x0 + 1, color); } else { startWrite(); writeLine(x0, y0, x1, y1, color); endWrite(); } } /**************************************************************************/ /*! @brief Draw a circle outline @param x0 Center-point x coordinate @param y0 Center-point y coordinate @param r Radius of circle @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawCircle(int16_t x0, int16_t y0, int16_t r, uint16_t color) { #if defined(ESP8266) yield(); #endif int16_t f = 1 - r; int16_t ddF_x = 1; int16_t ddF_y = -2 * r; int16_t x = 0; int16_t y = r; startWrite(); writePixel(x0, y0 + r, color); writePixel(x0, y0 - r, color); writePixel(x0 + r, y0, color); writePixel(x0 - r, y0, color); while (x < y) { if (f >= 0) { y--; ddF_y += 2; f += ddF_y; } x++; ddF_x += 2; f += ddF_x; writePixel(x0 + x, y0 + y, color); writePixel(x0 - x, y0 + y, color); writePixel(x0 + x, y0 - y, color); writePixel(x0 - x, y0 - y, color); writePixel(x0 + y, y0 + x, color); writePixel(x0 - y, y0 + x, color); writePixel(x0 + y, y0 - x, color); writePixel(x0 - y, y0 - x, color); } endWrite(); } /**************************************************************************/ /*! @brief Quarter-circle drawer, used to do circles and roundrects @param x0 Center-point x coordinate @param y0 Center-point y coordinate @param r Radius of circle @param cornername Mask bit #1 or bit #2 to indicate which quarters of the circle we're doing @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawCircleHelper(int16_t x0, int16_t y0, int16_t r, uint8_t cornername, uint16_t color) { int16_t f = 1 - r; int16_t ddF_x = 1; int16_t ddF_y = -2 * r; int16_t x = 0; int16_t y = r; while (x < y) { if (f >= 0) { y--; ddF_y += 2; f += ddF_y; } x++; ddF_x += 2; f += ddF_x; if (cornername & 0x4) { writePixel(x0 + x, y0 + y, color); writePixel(x0 + y, y0 + x, color); } if (cornername & 0x2) { writePixel(x0 + x, y0 - y, color); writePixel(x0 + y, y0 - x, color); } if (cornername & 0x8) { writePixel(x0 - y, y0 + x, color); writePixel(x0 - x, y0 + y, color); } if (cornername & 0x1) { writePixel(x0 - y, y0 - x, color); writePixel(x0 - x, y0 - y, color); } } } /**************************************************************************/ /*! @brief Draw a circle with filled color @param x0 Center-point x coordinate @param y0 Center-point y coordinate @param r Radius of circle @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::fillCircle(int16_t x0, int16_t y0, int16_t r, uint16_t color) { startWrite(); writeFastVLine(x0, y0 - r, 2 * r + 1, color); fillCircleHelper(x0, y0, r, 3, 0, color); endWrite(); } /**************************************************************************/ /*! @brief Quarter-circle drawer with fill, used for circles and roundrects @param x0 Center-point x coordinate @param y0 Center-point y coordinate @param r Radius of circle @param corners Mask bits indicating which quarters we're doing @param delta Offset from center-point, used for round-rects @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void Adafruit_GFX::fillCircleHelper(int16_t x0, int16_t y0, int16_t r, uint8_t corners, int16_t delta, uint16_t color) { int16_t f = 1 - r; int16_t ddF_x = 1; int16_t ddF_y = -2 * r; int16_t x = 0; int16_t y = r; int16_t px = x; int16_t py = y; delta++; // Avoid some +1's in the loop while (x < y) { if (f >= 0) { y--; ddF_y += 2; f += ddF_y; } x++; ddF_x += 2; f += ddF_x; // These checks avoid double-drawing certain lines, important // for the SSD1306 library which has an INVERT drawing mode. if (x < (y + 1)) { if (corners & 1) writeFastVLine(x0 + x, y0 - y, 2 * y + delta, color); if (corners & 2) writeFastVLine(x0 - x, y0 - y, 2 * y + delta, color); } if (y != py) { if (corners & 1) writeFastVLine(x0 + py, y0 - px, 2 * px + delta, color); if (corners & 2) writeFastVLine(x0 - py, y0 - px, 2 * px + delta, color); py = y; } px = x; } } /**************************************************************************/ /*! @brief Draw a rectangle with no fill color @param x Top left corner x coordinate @param y Top left corner y coordinate @param w Width in pixels @param h Height in pixels @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawRect(int16_t x, int16_t y, int16_t w, int16_t h, uint16_t color) { startWrite(); writeFastHLine(x, y, w, color); writeFastHLine(x, y + h - 1, w, color); writeFastVLine(x, y, h, color); writeFastVLine(x + w - 1, y, h, color); endWrite(); } /**************************************************************************/ /*! @brief Draw a rounded rectangle with no fill color @param x Top left corner x coordinate @param y Top left corner y coordinate @param w Width in pixels @param h Height in pixels @param r Radius of corner rounding @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawRoundRect(int16_t x, int16_t y, int16_t w, int16_t h, int16_t r, uint16_t color) { int16_t max_radius = ((w < h) ? w : h) / 2; // 1/2 minor axis if (r > max_radius) r = max_radius; // smarter version startWrite(); writeFastHLine(x + r, y, w - 2 * r, color); // Top writeFastHLine(x + r, y + h - 1, w - 2 * r, color); // Bottom writeFastVLine(x, y + r, h - 2 * r, color); // Left writeFastVLine(x + w - 1, y + r, h - 2 * r, color); // Right // draw four corners drawCircleHelper(x + r, y + r, r, 1, color); drawCircleHelper(x + w - r - 1, y + r, r, 2, color); drawCircleHelper(x + w - r - 1, y + h - r - 1, r, 4, color); drawCircleHelper(x + r, y + h - r - 1, r, 8, color); endWrite(); } /**************************************************************************/ /*! @brief Draw a rounded rectangle with fill color @param x Top left corner x coordinate @param y Top left corner y coordinate @param w Width in pixels @param h Height in pixels @param r Radius of corner rounding @param color 16-bit 5-6-5 Color to draw/fill with */ /**************************************************************************/ void Adafruit_GFX::fillRoundRect(int16_t x, int16_t y, int16_t w, int16_t h, int16_t r, uint16_t color) { int16_t max_radius = ((w < h) ? w : h) / 2; // 1/2 minor axis if (r > max_radius) r = max_radius; // smarter version startWrite(); writeFillRect(x + r, y, w - 2 * r, h, color); // draw four corners fillCircleHelper(x + w - r - 1, y + r, r, 1, h - 2 * r - 1, color); fillCircleHelper(x + r, y + r, r, 2, h - 2 * r - 1, color); endWrite(); } /**************************************************************************/ /*! @brief Draw a triangle with no fill color @param x0 Vertex #0 x coordinate @param y0 Vertex #0 y coordinate @param x1 Vertex #1 x coordinate @param y1 Vertex #1 y coordinate @param x2 Vertex #2 x coordinate @param y2 Vertex #2 y coordinate @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawTriangle(int16_t x0, int16_t y0, int16_t x1, int16_t y1, int16_t x2, int16_t y2, uint16_t color) { drawLine(x0, y0, x1, y1, color); drawLine(x1, y1, x2, y2, color); drawLine(x2, y2, x0, y0, color); } /**************************************************************************/ /*! @brief Draw a triangle with color-fill @param x0 Vertex #0 x coordinate @param y0 Vertex #0 y coordinate @param x1 Vertex #1 x coordinate @param y1 Vertex #1 y coordinate @param x2 Vertex #2 x coordinate @param y2 Vertex #2 y coordinate @param color 16-bit 5-6-5 Color to fill/draw with */ /**************************************************************************/ void Adafruit_GFX::fillTriangle(int16_t x0, int16_t y0, int16_t x1, int16_t y1, int16_t x2, int16_t y2, uint16_t color) { int16_t a, b, y, last; // Sort coordinates by Y order (y2 >= y1 >= y0) if (y0 > y1) { _swap_int16_t(y0, y1); _swap_int16_t(x0, x1); } if (y1 > y2) { _swap_int16_t(y2, y1); _swap_int16_t(x2, x1); } if (y0 > y1) { _swap_int16_t(y0, y1); _swap_int16_t(x0, x1); } startWrite(); if (y0 == y2) { // Handle awkward all-on-same-line case as its own thing a = b = x0; if (x1 < a) a = x1; else if (x1 > b) b = x1; if (x2 < a) a = x2; else if (x2 > b) b = x2; writeFastHLine(a, y0, b - a + 1, color); endWrite(); return; } int16_t dx01 = x1 - x0, dy01 = y1 - y0, dx02 = x2 - x0, dy02 = y2 - y0, dx12 = x2 - x1, dy12 = y2 - y1; int32_t sa = 0, sb = 0; // For upper part of triangle, find scanline crossings for segments // 0-1 and 0-2. If y1=y2 (flat-bottomed triangle), the scanline y1 // is included here (and second loop will be skipped, avoiding a /0 // error there), otherwise scanline y1 is skipped here and handled // in the second loop...which also avoids a /0 error here if y0=y1 // (flat-topped triangle). if (y1 == y2) last = y1; // Include y1 scanline else last = y1 - 1; // Skip it for (y = y0; y <= last; y++) { a = x0 + sa / dy01; b = x0 + sb / dy02; sa += dx01; sb += dx02; /* longhand: a = x0 + (x1 - x0) * (y - y0) / (y1 - y0); b = x0 + (x2 - x0) * (y - y0) / (y2 - y0); */ if (a > b) _swap_int16_t(a, b); writeFastHLine(a, y, b - a + 1, color); } // For lower part of triangle, find scanline crossings for segments // 0-2 and 1-2. This loop is skipped if y1=y2. sa = (int32_t)dx12 * (y - y1); sb = (int32_t)dx02 * (y - y0); for (; y <= y2; y++) { a = x1 + sa / dy12; b = x0 + sb / dy02; sa += dx12; sb += dx02; /* longhand: a = x1 + (x2 - x1) * (y - y1) / (y2 - y1); b = x0 + (x2 - x0) * (y - y0) / (y2 - y0); */ if (a > b) _swap_int16_t(a, b); writeFastHLine(a, y, b - a + 1, color); } endWrite(); } // BITMAP / XBITMAP / GRAYSCALE / RGB BITMAP FUNCTIONS --------------------- /**************************************************************************/ /*! @brief Draw a PROGMEM-resident 1-bit image at the specified (x,y) position, using the specified foreground color (unset bits are transparent). @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with monochrome bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawBitmap(int16_t x, int16_t y, const uint8_t bitmap[], int16_t w, int16_t h, uint16_t color) { int16_t byteWidth = (w + 7) / 8; // Bitmap scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = pgm_read_byte(&bitmap[j * byteWidth + i / 8]); if (byte & 0x80) writePixel(x + i, y, color); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a PROGMEM-resident 1-bit image at the specified (x,y) position, using the specified foreground (for set bits) and background (unset bits) colors. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with monochrome bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels @param color 16-bit 5-6-5 Color to draw pixels with @param bg 16-bit 5-6-5 Color to draw background with */ /**************************************************************************/ void Adafruit_GFX::drawBitmap(int16_t x, int16_t y, const uint8_t bitmap[], int16_t w, int16_t h, uint16_t color, uint16_t bg) { int16_t byteWidth = (w + 7) / 8; // Bitmap scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = pgm_read_byte(&bitmap[j * byteWidth + i / 8]); writePixel(x + i, y, (byte & 0x80) ? color : bg); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a RAM-resident 1-bit image at the specified (x,y) position, using the specified foreground color (unset bits are transparent). @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with monochrome bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels @param color 16-bit 5-6-5 Color to draw with */ /**************************************************************************/ void Adafruit_GFX::drawBitmap(int16_t x, int16_t y, uint8_t *bitmap, int16_t w, int16_t h, uint16_t color) { int16_t byteWidth = (w + 7) / 8; // Bitmap scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = bitmap[j * byteWidth + i / 8]; if (byte & 0x80) writePixel(x + i, y, color); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a RAM-resident 1-bit image at the specified (x,y) position, using the specified foreground (for set bits) and background (unset bits) colors. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with monochrome bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels @param color 16-bit 5-6-5 Color to draw pixels with @param bg 16-bit 5-6-5 Color to draw background with */ /**************************************************************************/ void Adafruit_GFX::drawBitmap(int16_t x, int16_t y, uint8_t *bitmap, int16_t w, int16_t h, uint16_t color, uint16_t bg) { int16_t byteWidth = (w + 7) / 8; // Bitmap scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = bitmap[j * byteWidth + i / 8]; writePixel(x + i, y, (byte & 0x80) ? color : bg); } } endWrite(); } /**************************************************************************/ /*! @brief Draw PROGMEM-resident XBitMap Files (*.xbm), exported from GIMP. Usage: Export from GIMP to *.xbm, rename *.xbm to *.c and open in editor. C Array can be directly used with this function. There is no RAM-resident version of this function; if generating bitmaps in RAM, use the format defined by drawBitmap() and call that instead. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with monochrome bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels @param color 16-bit 5-6-5 Color to draw pixels with */ /**************************************************************************/ void Adafruit_GFX::drawXBitmap(int16_t x, int16_t y, const uint8_t bitmap[], int16_t w, int16_t h, uint16_t color) { int16_t byteWidth = (w + 7) / 8; // Bitmap scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte >>= 1; else byte = pgm_read_byte(&bitmap[j * byteWidth + i / 8]); // Nearly identical to drawBitmap(), only the bit order // is reversed here (left-to-right = LSB to MSB): if (byte & 0x01) writePixel(x + i, y, color); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a PROGMEM-resident 8-bit image (grayscale) at the specified (x,y) pos. Specifically for 8-bit display devices such as IS31FL3731; no color reduction/expansion is performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with grayscale bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawGrayscaleBitmap(int16_t x, int16_t y, const uint8_t bitmap[], int16_t w, int16_t h) { startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { writePixel(x + i, y, (uint8_t)pgm_read_byte(&bitmap[j * w + i])); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a RAM-resident 8-bit image (grayscale) at the specified (x,y) pos. Specifically for 8-bit display devices such as IS31FL3731; no color reduction/expansion is performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with grayscale bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawGrayscaleBitmap(int16_t x, int16_t y, uint8_t *bitmap, int16_t w, int16_t h) { startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { writePixel(x + i, y, bitmap[j * w + i]); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a PROGMEM-resident 8-bit image (grayscale) with a 1-bit mask (set bits = opaque, unset bits = clear) at the specified (x,y) position. BOTH buffers (grayscale and mask) must be PROGMEM-resident. Specifically for 8-bit display devices such as IS31FL3731; no color reduction/expansion is performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with grayscale bitmap @param mask byte array with mask bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawGrayscaleBitmap(int16_t x, int16_t y, const uint8_t bitmap[], const uint8_t mask[], int16_t w, int16_t h) { int16_t bw = (w + 7) / 8; // Bitmask scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = pgm_read_byte(&mask[j * bw + i / 8]); if (byte & 0x80) { writePixel(x + i, y, (uint8_t)pgm_read_byte(&bitmap[j * w + i])); } } } endWrite(); } /**************************************************************************/ /*! @brief Draw a RAM-resident 8-bit image (grayscale) with a 1-bit mask (set bits = opaque, unset bits = clear) at the specified (x,y) position. BOTH buffers (grayscale and mask) must be RAM-residentt, no mix-and-match Specifically for 8-bit display devices such as IS31FL3731; no color reduction/expansion is performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with grayscale bitmap @param mask byte array with mask bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawGrayscaleBitmap(int16_t x, int16_t y, uint8_t *bitmap, uint8_t *mask, int16_t w, int16_t h) { int16_t bw = (w + 7) / 8; // Bitmask scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = mask[j * bw + i / 8]; if (byte & 0x80) { writePixel(x + i, y, bitmap[j * w + i]); } } } endWrite(); } /**************************************************************************/ /*! @brief Draw a PROGMEM-resident 16-bit image (RGB 5/6/5) at the specified (x,y) position. For 16-bit display devices; no color reduction performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with 16-bit color bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawRGBBitmap(int16_t x, int16_t y, const uint16_t bitmap[], int16_t w, int16_t h) { startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { writePixel(x + i, y, pgm_read_word(&bitmap[j * w + i])); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a RAM-resident 16-bit image (RGB 5/6/5) at the specified (x,y) position. For 16-bit display devices; no color reduction performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with 16-bit color bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawRGBBitmap(int16_t x, int16_t y, uint16_t *bitmap, int16_t w, int16_t h) { startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { writePixel(x + i, y, bitmap[j * w + i]); } } endWrite(); } /**************************************************************************/ /*! @brief Draw a PROGMEM-resident 16-bit image (RGB 5/6/5) with a 1-bit mask (set bits = opaque, unset bits = clear) at the specified (x,y) position. BOTH buffers (color and mask) must be PROGMEM-resident. For 16-bit display devices; no color reduction performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with 16-bit color bitmap @param mask byte array with monochrome mask bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawRGBBitmap(int16_t x, int16_t y, const uint16_t bitmap[], const uint8_t mask[], int16_t w, int16_t h) { int16_t bw = (w + 7) / 8; // Bitmask scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = pgm_read_byte(&mask[j * bw + i / 8]); if (byte & 0x80) { writePixel(x + i, y, pgm_read_word(&bitmap[j * w + i])); } } } endWrite(); } /**************************************************************************/ /*! @brief Draw a RAM-resident 16-bit image (RGB 5/6/5) with a 1-bit mask (set bits = opaque, unset bits = clear) at the specified (x,y) position. BOTH buffers (color and mask) must be RAM-resident. For 16-bit display devices; no color reduction performed. @param x Top left corner x coordinate @param y Top left corner y coordinate @param bitmap byte array with 16-bit color bitmap @param mask byte array with monochrome mask bitmap @param w Width of bitmap in pixels @param h Height of bitmap in pixels */ /**************************************************************************/ void Adafruit_GFX::drawRGBBitmap(int16_t x, int16_t y, uint16_t *bitmap, uint8_t *mask, int16_t w, int16_t h) { int16_t bw = (w + 7) / 8; // Bitmask scanline pad = whole byte uint8_t byte = 0; startWrite(); for (int16_t j = 0; j < h; j++, y++) { for (int16_t i = 0; i < w; i++) { if (i & 7) byte <<= 1; else byte = mask[j * bw + i / 8]; if (byte & 0x80) { writePixel(x + i, y, bitmap[j * w + i]); } } } endWrite(); } // TEXT- AND CHARACTER-HANDLING FUNCTIONS ---------------------------------- // Draw a character /**************************************************************************/ /*! @brief Draw a single character @param x Bottom left corner x coordinate @param y Bottom left corner y coordinate @param c The 8-bit font-indexed character (likely ascii) @param color 16-bit 5-6-5 Color to draw chraracter with @param bg 16-bit 5-6-5 Color to fill background with (if same as color, no background) @param size Font magnification level, 1 is 'original' size */ /**************************************************************************/ void Adafruit_GFX::drawChar(int16_t x, int16_t y, unsigned char c, uint16_t color, uint16_t bg, uint8_t size) { drawChar(x, y, c, color, bg, size, size); } // Draw a character /**************************************************************************/ /*! @brief Draw a single character @param x Bottom left corner x coordinate @param y Bottom left corner y coordinate @param c The 8-bit font-indexed character (likely ascii) @param color 16-bit 5-6-5 Color to draw chraracter with @param bg 16-bit 5-6-5 Color to fill background with (if same as color, no background) @param size_x Font magnification level in X-axis, 1 is 'original' size @param size_y Font magnification level in Y-axis, 1 is 'original' size */ /**************************************************************************/ void Adafruit_GFX::drawChar(int16_t x, int16_t y, unsigned char c, uint16_t color, uint16_t bg, uint8_t size_x, uint8_t size_y) { if (!gfxFont) { // 'Classic' built-in font if ((x >= _width) || // Clip right (y >= _height) || // Clip bottom ((x + 6 * size_x - 1) < 0) || // Clip left ((y + 8 * size_y - 1) < 0)) // Clip top return; if (!_cp437 && (c >= 176)) c++; // Handle 'classic' charset behavior startWrite(); for (int8_t i = 0; i < 5; i++) { // Char bitmap = 5 columns uint8_t line = pgm_read_byte(&font[c * 5 + i]); for (int8_t j = 0; j < 8; j++, line >>= 1) { if (line & 1) { if (size_x == 1 && size_y == 1) writePixel(x + i, y + j, color); else writeFillRect(x + i * size_x, y + j * size_y, size_x, size_y, color); } else if (bg != color) { if (size_x == 1 && size_y == 1) writePixel(x + i, y + j, bg); else writeFillRect(x + i * size_x, y + j * size_y, size_x, size_y, bg); } } } if (bg != color) { // If opaque, draw vertical line for last column if (size_x == 1 && size_y == 1) writeFastVLine(x + 5, y, 8, bg); else writeFillRect(x + 5 * size_x, y, size_x, 8 * size_y, bg); } endWrite(); } else { // Custom font // Character is assumed previously filtered by write() to eliminate // newlines, returns, non-printable characters, etc. Calling // drawChar() directly with 'bad' characters of font may cause mayhem! c -= (uint8_t)pgm_read_byte(&gfxFont->first); GFXglyph *glyph = pgm_read_glyph_ptr(gfxFont, c); uint8_t *bitmap = pgm_read_bitmap_ptr(gfxFont); uint16_t bo = pgm_read_word(&glyph->bitmapOffset); uint8_t w = pgm_read_byte(&glyph->width), h = pgm_read_byte(&glyph->height); int8_t xo = pgm_read_byte(&glyph->xOffset), yo = pgm_read_byte(&glyph->yOffset); uint8_t xx, yy, bits = 0, bit = 0; int16_t xo16 = 0, yo16 = 0; if (size_x > 1 || size_y > 1) { xo16 = xo; yo16 = yo; } // Todo: Add character clipping here // NOTE: THERE IS NO 'BACKGROUND' COLOR OPTION ON CUSTOM FONTS. // THIS IS ON PURPOSE AND BY DESIGN. The background color feature // has typically been used with the 'classic' font to overwrite old // screen contents with new data. This ONLY works because the // characters are a uniform size; it's not a sensible thing to do with // proportionally-spaced fonts with glyphs of varying sizes (and that // may overlap). To replace previously-drawn text when using a custom // font, use the getTextBounds() function to determine the smallest // rectangle encompassing a string, erase the area with fillRect(), // then draw new text. This WILL infortunately 'blink' the text, but // is unavoidable. Drawing 'background' pixels will NOT fix this, // only creates a new set of problems. Have an idea to work around // this (a canvas object type for MCUs that can afford the RAM and // displays supporting setAddrWindow() and pushColors()), but haven't // implemented this yet. startWrite(); for (yy = 0; yy < h; yy++) { for (xx = 0; xx < w; xx++) { if (!(bit++ & 7)) { bits = pgm_read_byte(&bitmap[bo++]); } if (bits & 0x80) { if (size_x == 1 && size_y == 1) { writePixel(x + xo + xx, y + yo + yy, color); } else { writeFillRect(x + (xo16 + xx) * size_x, y + (yo16 + yy) * size_y, size_x, size_y, color); } } bits <<= 1; } } endWrite(); } // End classic vs custom font } /**************************************************************************/ /*! @brief Print one byte/character of data, used to support print() @param c The 8-bit ascii character to write */ /**************************************************************************/ size_t Adafruit_GFX::write(uint8_t c) { if (!gfxFont) { // 'Classic' built-in font if (c == '\n') { // Newline? cursor_x = 0; // Reset x to zero, cursor_y += textsize_y * 8; // advance y one line } else if (c != '\r') { // Ignore carriage returns if (wrap && ((cursor_x + textsize_x * 6) > _width)) { // Off right? cursor_x = 0; // Reset x to zero, cursor_y += textsize_y * 8; // advance y one line } drawChar(cursor_x, cursor_y, c, textcolor, textbgcolor, textsize_x, textsize_y); cursor_x += textsize_x * 6; // Advance x one char } } else { // Custom font if (c == '\n') { cursor_x = 0; cursor_y += (int16_t)textsize_y * (uint8_t)pgm_read_byte(&gfxFont->yAdvance); } else if (c != '\r') { uint8_t first = pgm_read_byte(&gfxFont->first); if ((c >= first) && (c <= (uint8_t)pgm_read_byte(&gfxFont->last))) { GFXglyph *glyph = pgm_read_glyph_ptr(gfxFont, c - first); uint8_t w = pgm_read_byte(&glyph->width), h = pgm_read_byte(&glyph->height); if ((w > 0) && (h > 0)) { // Is there an associated bitmap? int16_t xo = (int8_t)pgm_read_byte(&glyph->xOffset); // sic if (wrap && ((cursor_x + textsize_x * (xo + w)) > _width)) { cursor_x = 0; cursor_y += (int16_t)textsize_y * (uint8_t)pgm_read_byte(&gfxFont->yAdvance); } drawChar(cursor_x, cursor_y, c, textcolor, textbgcolor, textsize_x, textsize_y); } cursor_x += (uint8_t)pgm_read_byte(&glyph->xAdvance) * (int16_t)textsize_x; } } } return 1; } /**************************************************************************/ /*! @brief Set text 'magnification' size. Each increase in s makes 1 pixel that much bigger. @param s Desired text size. 1 is default 6x8, 2 is 12x16, 3 is 18x24, etc */ /**************************************************************************/ void Adafruit_GFX::setTextSize(uint8_t s) { setTextSize(s, s); } /**************************************************************************/ /*! @brief Set text 'magnification' size. Each increase in s makes 1 pixel that much bigger. @param s_x Desired text width magnification level in X-axis. 1 is default @param s_y Desired text width magnification level in Y-axis. 1 is default */ /**************************************************************************/ void Adafruit_GFX::setTextSize(uint8_t s_x, uint8_t s_y) { textsize_x = (s_x > 0) ? s_x : 1; textsize_y = (s_y > 0) ? s_y : 1; } /**************************************************************************/ /*! @brief Set rotation setting for display @param x 0 thru 3 corresponding to 4 cardinal rotations */ /**************************************************************************/ void Adafruit_GFX::setRotation(uint8_t x) { rotation = (x & 3); switch (rotation) { case 0: case 2: _width = WIDTH; _height = HEIGHT; break; case 1: case 3: _width = HEIGHT; _height = WIDTH; break; } } /**************************************************************************/ /*! @brief Set the font to display when print()ing, either custom or default @param f The GFXfont object, if NULL use built in 6x8 font */ /**************************************************************************/ void Adafruit_GFX::setFont(const GFXfont *f) { if (f) { // Font struct pointer passed in? if (!gfxFont) { // And no current font struct? // Switching from classic to new font behavior. // Move cursor pos down 6 pixels so it's on baseline. cursor_y += 6; } } else if (gfxFont) { // NULL passed. Current font struct defined? // Switching from new to classic font behavior. // Move cursor pos up 6 pixels so it's at top-left of char. cursor_y -= 6; } gfxFont = (GFXfont *)f; } /**************************************************************************/ /*! @brief Helper to determine size of a character with current font/size. Broke this out as it's used by both the PROGMEM- and RAM-resident getTextBounds() functions. @param c The ascii character in question @param x Pointer to x location of character @param y Pointer to y location of character @param minx Minimum clipping value for X @param miny Minimum clipping value for Y @param maxx Maximum clipping value for X @param maxy Maximum clipping value for Y */ /**************************************************************************/ void Adafruit_GFX::charBounds(unsigned char c, int16_t *x, int16_t *y, int16_t *minx, int16_t *miny, int16_t *maxx, int16_t *maxy) { if (gfxFont) { if (c == '\n') { // Newline? *x = 0; // Reset x to zero, advance y by one line *y += textsize_y * (uint8_t)pgm_read_byte(&gfxFont->yAdvance); } else if (c != '\r') { // Not a carriage return; is normal char uint8_t first = pgm_read_byte(&gfxFont->first), last = pgm_read_byte(&gfxFont->last); if ((c >= first) && (c <= last)) { // Char present in this font? GFXglyph *glyph = pgm_read_glyph_ptr(gfxFont, c - first); uint8_t gw = pgm_read_byte(&glyph->width), gh = pgm_read_byte(&glyph->height), xa = pgm_read_byte(&glyph->xAdvance); int8_t xo = pgm_read_byte(&glyph->xOffset), yo = pgm_read_byte(&glyph->yOffset); if (wrap && ((*x + (((int16_t)xo + gw) * textsize_x)) > _width)) { *x = 0; // Reset x to zero, advance y by one line *y += textsize_y * (uint8_t)pgm_read_byte(&gfxFont->yAdvance); } int16_t tsx = (int16_t)textsize_x, tsy = (int16_t)textsize_y, x1 = *x + xo * tsx, y1 = *y + yo * tsy, x2 = x1 + gw * tsx - 1, y2 = y1 + gh * tsy - 1; if (x1 < *minx) *minx = x1; if (y1 < *miny) *miny = y1; if (x2 > *maxx) *maxx = x2; if (y2 > *maxy) *maxy = y2; *x += xa * tsx; } } } else { // Default font if (c == '\n') { // Newline? *x = 0; // Reset x to zero, *y += textsize_y * 8; // advance y one line // min/max x/y unchaged -- that waits for next 'normal' character } else if (c != '\r') { // Normal char; ignore carriage returns if (wrap && ((*x + textsize_x * 6) > _width)) { // Off right? *x = 0; // Reset x to zero, *y += textsize_y * 8; // advance y one line } int x2 = *x + textsize_x * 6 - 1, // Lower-right pixel of char y2 = *y + textsize_y * 8 - 1; if (x2 > *maxx) *maxx = x2; // Track max x, y if (y2 > *maxy) *maxy = y2; if (*x < *minx) *minx = *x; // Track min x, y if (*y < *miny) *miny = *y; *x += textsize_x * 6; // Advance x one char } } } /**************************************************************************/ /*! @brief Helper to determine size of a string with current font/size. Pass string and a cursor position, returns UL corner and W,H. @param str The ascii string to measure @param x The current cursor X @param y The current cursor Y @param x1 The boundary X coordinate, set by function @param y1 The boundary Y coordinate, set by function @param w The boundary width, set by function @param h The boundary height, set by function */ /**************************************************************************/ void Adafruit_GFX::getTextBounds(const char *str, int16_t x, int16_t y, int16_t *x1, int16_t *y1, uint16_t *w, uint16_t *h) { uint8_t c; // Current character *x1 = x; *y1 = y; *w = *h = 0; int16_t minx = _width, miny = _height, maxx = -1, maxy = -1; while ((c = *str++)) charBounds(c, &x, &y, &minx, &miny, &maxx, &maxy); if (maxx >= minx) { *x1 = minx; *w = maxx - minx + 1; } if (maxy >= miny) { *y1 = miny; *h = maxy - miny + 1; } } /**************************************************************************/ /*! @brief Helper to determine size of a string with current font/size. Pass string and a cursor position, returns UL corner and W,H. @param str The ascii string to measure (as an arduino String() class) @param x The current cursor X @param y The current cursor Y @param x1 The boundary X coordinate, set by function @param y1 The boundary Y coordinate, set by function @param w The boundary width, set by function @param h The boundary height, set by function */ /**************************************************************************/ void Adafruit_GFX::getTextBounds(const String &str, int16_t x, int16_t y, int16_t *x1, int16_t *y1, uint16_t *w, uint16_t *h) { if (str.length() != 0) { getTextBounds(const_cast<char *>(str.c_str()), x, y, x1, y1, w, h); } } /**************************************************************************/ /*! @brief Helper to determine size of a PROGMEM string with current font/size. Pass string and a cursor position, returns UL corner and W,H. @param str The flash-memory ascii string to measure @param x The current cursor X @param y The current cursor Y @param x1 The boundary X coordinate, set by function @param y1 The boundary Y coordinate, set by function @param w The boundary width, set by function @param h The boundary height, set by function */ /**************************************************************************/ void Adafruit_GFX::getTextBounds(const __FlashStringHelper *str, int16_t x, int16_t y, int16_t *x1, int16_t *y1, uint16_t *w, uint16_t *h) { uint8_t *s = (uint8_t *)str, c; *x1 = x; *y1 = y; *w = *h = 0; int16_t minx = _width, miny = _height, maxx = -1, maxy = -1; while ((c = pgm_read_byte(s++))) charBounds(c, &x, &y, &minx, &miny, &maxx, &maxy); if (maxx >= minx) { *x1 = minx; *w = maxx - minx + 1; } if (maxy >= miny) { *y1 = miny; *h = maxy - miny + 1; } } /**************************************************************************/ /*! @brief Invert the display (ideally using built-in hardware command) @param i True if you want to invert, false to make 'normal' */ /**************************************************************************/ void Adafruit_GFX::invertDisplay(boolean i) { // Do nothing, must be subclassed if supported by hardware } /***************************************************************************/ /**************************************************************************/ /*! @brief Create a simple drawn button UI element */ /**************************************************************************/ Adafruit_GFX_Button::Adafruit_GFX_Button(void) { _gfx = 0; } /**************************************************************************/ /*! @brief Initialize button with our desired color/size/settings @param gfx Pointer to our display so we can draw to it! @param x The X coordinate of the center of the button @param y The Y coordinate of the center of the button @param w Width of the buttton @param h Height of the buttton @param outline Color of the outline (16-bit 5-6-5 standard) @param fill Color of the button fill (16-bit 5-6-5 standard) @param textcolor Color of the button label (16-bit 5-6-5 standard) @param label Ascii string of the text inside the button @param textsize The font magnification of the label text */ /**************************************************************************/ // Classic initButton() function: pass center & size void Adafruit_GFX_Button::initButton(Adafruit_GFX *gfx, int16_t x, int16_t y, uint16_t w, uint16_t h, uint16_t outline, uint16_t fill, uint16_t textcolor, char *label, uint8_t textsize) { // Tweak arguments and pass to the newer initButtonUL() function... initButtonUL(gfx, x - (w / 2), y - (h / 2), w, h, outline, fill, textcolor, label, textsize); } /**************************************************************************/ /*! @brief Initialize button with our desired color/size/settings @param gfx Pointer to our display so we can draw to it! @param x The X coordinate of the center of the button @param y The Y coordinate of the center of the button @param w Width of the buttton @param h Height of the buttton @param outline Color of the outline (16-bit 5-6-5 standard) @param fill Color of the button fill (16-bit 5-6-5 standard) @param textcolor Color of the button label (16-bit 5-6-5 standard) @param label Ascii string of the text inside the button @param textsize_x The font magnification in X-axis of the label text @param textsize_y The font magnification in Y-axis of the label text */ /**************************************************************************/ // Classic initButton() function: pass center & size void Adafruit_GFX_Button::initButton(Adafruit_GFX *gfx, int16_t x, int16_t y, uint16_t w, uint16_t h, uint16_t outline, uint16_t fill, uint16_t textcolor, char *label, uint8_t textsize_x, uint8_t textsize_y) { // Tweak arguments and pass to the newer initButtonUL() function... initButtonUL(gfx, x - (w / 2), y - (h / 2), w, h, outline, fill, textcolor, label, textsize_x, textsize_y); } /**************************************************************************/ /*! @brief Initialize button with our desired color/size/settings, with upper-left coordinates @param gfx Pointer to our display so we can draw to it! @param x1 The X coordinate of the Upper-Left corner of the button @param y1 The Y coordinate of the Upper-Left corner of the button @param w Width of the buttton @param h Height of the buttton @param outline Color of the outline (16-bit 5-6-5 standard) @param fill Color of the button fill (16-bit 5-6-5 standard) @param textcolor Color of the button label (16-bit 5-6-5 standard) @param label Ascii string of the text inside the button @param textsize The font magnification of the label text */ /**************************************************************************/ void Adafruit_GFX_Button::initButtonUL(Adafruit_GFX *gfx, int16_t x1, int16_t y1, uint16_t w, uint16_t h, uint16_t outline, uint16_t fill, uint16_t textcolor, char *label, uint8_t textsize) { initButtonUL(gfx, x1, y1, w, h, outline, fill, textcolor, label, textsize, textsize); } /**************************************************************************/ /*! @brief Initialize button with our desired color/size/settings, with upper-left coordinates @param gfx Pointer to our display so we can draw to it! @param x1 The X coordinate of the Upper-Left corner of the button @param y1 The Y coordinate of the Upper-Left corner of the button @param w Width of the buttton @param h Height of the buttton @param outline Color of the outline (16-bit 5-6-5 standard) @param fill Color of the button fill (16-bit 5-6-5 standard) @param textcolor Color of the button label (16-bit 5-6-5 standard) @param label Ascii string of the text inside the button @param textsize_x The font magnification in X-axis of the label text @param textsize_y The font magnification in Y-axis of the label text */ /**************************************************************************/ void Adafruit_GFX_Button::initButtonUL(Adafruit_GFX *gfx, int16_t x1, int16_t y1, uint16_t w, uint16_t h, uint16_t outline, uint16_t fill, uint16_t textcolor, char *label, uint8_t textsize_x, uint8_t textsize_y) { _x1 = x1; _y1 = y1; _w = w; _h = h; _outlinecolor = outline; _fillcolor = fill; _textcolor = textcolor; _textsize_x = textsize_x; _textsize_y = textsize_y; _gfx = gfx; strncpy(_label, label, 9); } /**************************************************************************/ /*! @brief Draw the button on the screen @param inverted Whether to draw with fill/text swapped to indicate 'pressed' */ /**************************************************************************/ void Adafruit_GFX_Button::drawButton(boolean inverted) { uint16_t fill, outline, text; if (!inverted) { fill = _fillcolor; outline = _outlinecolor; text = _textcolor; } else { fill = _textcolor; outline = _outlinecolor; text = _fillcolor; } uint8_t r = min(_w, _h) / 4; // Corner radius _gfx->fillRoundRect(_x1, _y1, _w, _h, r, fill); _gfx->drawRoundRect(_x1, _y1, _w, _h, r, outline); _gfx->setCursor(_x1 + (_w / 2) - (strlen(_label) * 3 * _textsize_x), _y1 + (_h / 2) - (4 * _textsize_y)); _gfx->setTextColor(text); _gfx->setTextSize(_textsize_x, _textsize_y); _gfx->print(_label); } /**************************************************************************/ /*! @brief Helper to let us know if a coordinate is within the bounds of the button @param x The X coordinate to check @param y The Y coordinate to check @returns True if within button graphics outline */ /**************************************************************************/ boolean Adafruit_GFX_Button::contains(int16_t x, int16_t y) { return ((x >= _x1) && (x < (int16_t)(_x1 + _w)) && (y >= _y1) && (y < (int16_t)(_y1 + _h))); } /**************************************************************************/ /*! @brief Query whether the button was pressed since we last checked state @returns True if was not-pressed before, now is. */ /**************************************************************************/ boolean Adafruit_GFX_Button::justPressed() { return (currstate && !laststate); } /**************************************************************************/ /*! @brief Query whether the button was released since we last checked state @returns True if was pressed before, now is not. */ /**************************************************************************/ boolean Adafruit_GFX_Button::justReleased() { return (!currstate && laststate); } // ------------------------------------------------------------------------- // GFXcanvas1, GFXcanvas8 and GFXcanvas16 (currently a WIP, don't get too // comfy with the implementation) provide 1-, 8- and 16-bit offscreen // canvases, the address of which can be passed to drawBitmap() or // pushColors() (the latter appears only in a couple of GFX-subclassed TFT // libraries at this time). This is here mostly to help with the recently- // added proportionally-spaced fonts; adds a way to refresh a section of the // screen without a massive flickering clear-and-redraw...but maybe you'll // find other uses too. VERY RAM-intensive, since the buffer is in MCU // memory and not the display driver...GXFcanvas1 might be minimally useful // on an Uno-class board, but this and the others are much more likely to // require at least a Mega or various recent ARM-type boards (recommended, // as the text+bitmap draw can be pokey). GFXcanvas1 requires 1 bit per // pixel (rounded up to nearest byte per scanline), GFXcanvas8 is 1 byte // per pixel (no scanline pad), and GFXcanvas16 uses 2 bytes per pixel (no // scanline pad). // NOT EXTENSIVELY TESTED YET. MAY CONTAIN WORST BUGS KNOWN TO HUMANKIND. /**************************************************************************/ /*! @brief Instatiate a GFX 1-bit canvas context for graphics @param w Display width, in pixels @param h Display height, in pixels */ /**************************************************************************/ GFXcanvas1::GFXcanvas1(uint16_t w, uint16_t h) : Adafruit_GFX(w, h) { uint16_t bytes = ((w + 7) / 8) * h; if ((buffer = (uint8_t *)malloc(bytes))) { memset(buffer, 0, bytes); } } /**************************************************************************/ /*! @brief Delete the canvas, free memory */ /**************************************************************************/ GFXcanvas1::~GFXcanvas1(void) { if (buffer) free(buffer); } /**************************************************************************/ /*! @brief Draw a pixel to the canvas framebuffer @param x x coordinate @param y y coordinate @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void GFXcanvas1::drawPixel(int16_t x, int16_t y, uint16_t color) { #ifdef __AVR__ // Bitmask tables of 0x80>>X and ~(0x80>>X), because X>>Y is slow on AVR static const uint8_t PROGMEM GFXsetBit[] = {0x80, 0x40, 0x20, 0x10, 0x08, 0x04, 0x02, 0x01}, GFXclrBit[] = {0x7F, 0xBF, 0xDF, 0xEF, 0xF7, 0xFB, 0xFD, 0xFE}; #endif if (buffer) { if ((x < 0) || (y < 0) || (x >= _width) || (y >= _height)) return; int16_t t; switch (rotation) { case 1: t = x; x = WIDTH - 1 - y; y = t; break; case 2: x = WIDTH - 1 - x; y = HEIGHT - 1 - y; break; case 3: t = x; x = y; y = HEIGHT - 1 - t; break; } uint8_t *ptr = &buffer[(x / 8) + y * ((WIDTH + 7) / 8)]; #ifdef __AVR__ if (color) *ptr |= pgm_read_byte(&GFXsetBit[x & 7]); else *ptr &= pgm_read_byte(&GFXclrBit[x & 7]); #else if (color) *ptr |= 0x80 >> (x & 7); else *ptr &= ~(0x80 >> (x & 7)); #endif } } /**************************************************************************/ /*! @brief Fill the framebuffer completely with one color @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void GFXcanvas1::fillScreen(uint16_t color) { if (buffer) { uint16_t bytes = ((WIDTH + 7) / 8) * HEIGHT; memset(buffer, color ? 0xFF : 0x00, bytes); } } /**************************************************************************/ /*! @brief Instatiate a GFX 8-bit canvas context for graphics @param w Display width, in pixels @param h Display height, in pixels */ /**************************************************************************/ GFXcanvas8::GFXcanvas8(uint16_t w, uint16_t h) : Adafruit_GFX(w, h) { uint32_t bytes = w * h; if ((buffer = (uint8_t *)malloc(bytes))) { memset(buffer, 0, bytes); } } /**************************************************************************/ /*! @brief Delete the canvas, free memory */ /**************************************************************************/ GFXcanvas8::~GFXcanvas8(void) { if (buffer) free(buffer); } /**************************************************************************/ /*! @brief Draw a pixel to the canvas framebuffer @param x x coordinate @param y y coordinate @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void GFXcanvas8::drawPixel(int16_t x, int16_t y, uint16_t color) { if (buffer) { if ((x < 0) || (y < 0) || (x >= _width) || (y >= _height)) return; int16_t t; switch (rotation) { case 1: t = x; x = WIDTH - 1 - y; y = t; break; case 2: x = WIDTH - 1 - x; y = HEIGHT - 1 - y; break; case 3: t = x; x = y; y = HEIGHT - 1 - t; break; } buffer[x + y * WIDTH] = color; } } /**************************************************************************/ /*! @brief Fill the framebuffer completely with one color @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void GFXcanvas8::fillScreen(uint16_t color) { if (buffer) { memset(buffer, color, WIDTH * HEIGHT); } } void GFXcanvas8::writeFastHLine(int16_t x, int16_t y, int16_t w, uint16_t color) { if ((x >= _width) || (y < 0) || (y >= _height)) return; int16_t x2 = x + w - 1; if (x2 < 0) return; // Clip left/right if (x < 0) { x = 0; w = x2 + 1; } if (x2 >= _width) w = _width - x; int16_t t; switch (rotation) { case 1: t = x; x = WIDTH - 1 - y; y = t; break; case 2: x = WIDTH - 1 - x; y = HEIGHT - 1 - y; break; case 3: t = x; x = y; y = HEIGHT - 1 - t; break; } memset(buffer + y * WIDTH + x, color, w); } /**************************************************************************/ /*! @brief Instatiate a GFX 16-bit canvas context for graphics @param w Display width, in pixels @param h Display height, in pixels */ /**************************************************************************/ GFXcanvas16::GFXcanvas16(uint16_t w, uint16_t h) : Adafruit_GFX(w, h) { uint32_t bytes = w * h * 2; if ((buffer = (uint16_t *)malloc(bytes))) { memset(buffer, 0, bytes); } } /**************************************************************************/ /*! @brief Delete the canvas, free memory */ /**************************************************************************/ GFXcanvas16::~GFXcanvas16(void) { if (buffer) free(buffer); } /**************************************************************************/ /*! @brief Draw a pixel to the canvas framebuffer @param x x coordinate @param y y coordinate @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void GFXcanvas16::drawPixel(int16_t x, int16_t y, uint16_t color) { if (buffer) { if ((x < 0) || (y < 0) || (x >= _width) || (y >= _height)) return; int16_t t; switch (rotation) { case 1: t = x; x = WIDTH - 1 - y; y = t; break; case 2: x = WIDTH - 1 - x; y = HEIGHT - 1 - y; break; case 3: t = x; x = y; y = HEIGHT - 1 - t; break; } buffer[x + y * WIDTH] = color; } } /**************************************************************************/ /*! @brief Fill the framebuffer completely with one color @param color 16-bit 5-6-5 Color to fill with */ /**************************************************************************/ void GFXcanvas16::fillScreen(uint16_t color) { if (buffer) { uint8_t hi = color >> 8, lo = color & 0xFF; if (hi == lo) { memset(buffer, lo, WIDTH * HEIGHT * 2); } else { uint32_t i, pixels = WIDTH * HEIGHT; for (i = 0; i < pixels; i++) buffer[i] = color; } } } /**************************************************************************/ /*! @brief Reverses the "endian-ness" of each 16-bit pixel within the canvas; little-endian to big-endian, or big-endian to little. Most microcontrollers (such as SAMD) are little-endian, while most displays tend toward big-endianness. All the drawing functions (including RGB bitmap drawing) take care of this automatically, but some specialized code (usually involving DMA) can benefit from having pixel data already in the display-native order. Note that this does NOT convert to a SPECIFIC endian-ness, it just flips the bytes within each word. */ /**************************************************************************/ void GFXcanvas16::byteSwap(void) { if (buffer) { uint32_t i, pixels = WIDTH * HEIGHT; for (i = 0; i < pixels; i++) buffer[i] = __builtin_bswap16(buffer[i]); } } |

Stay Tuned,

Frank