/*

Name: Teensy_I2C_Sniffer_V6.ino

Created: 1/4/2020 8:40:20 AM

Author: FRANKNEWXPS15\Frank

This is a port of my Excel VBA code into Arduino/Teensy C++ language.

It parses the exact same sample data as the Excel program, so it should

produce the exact same I2C sequences.

The captured sample data to be parsed is held in the 'simdata' array.

The original VBA code is saved in 'ExcelVBACode.txt'

*/

/* 'Notes:

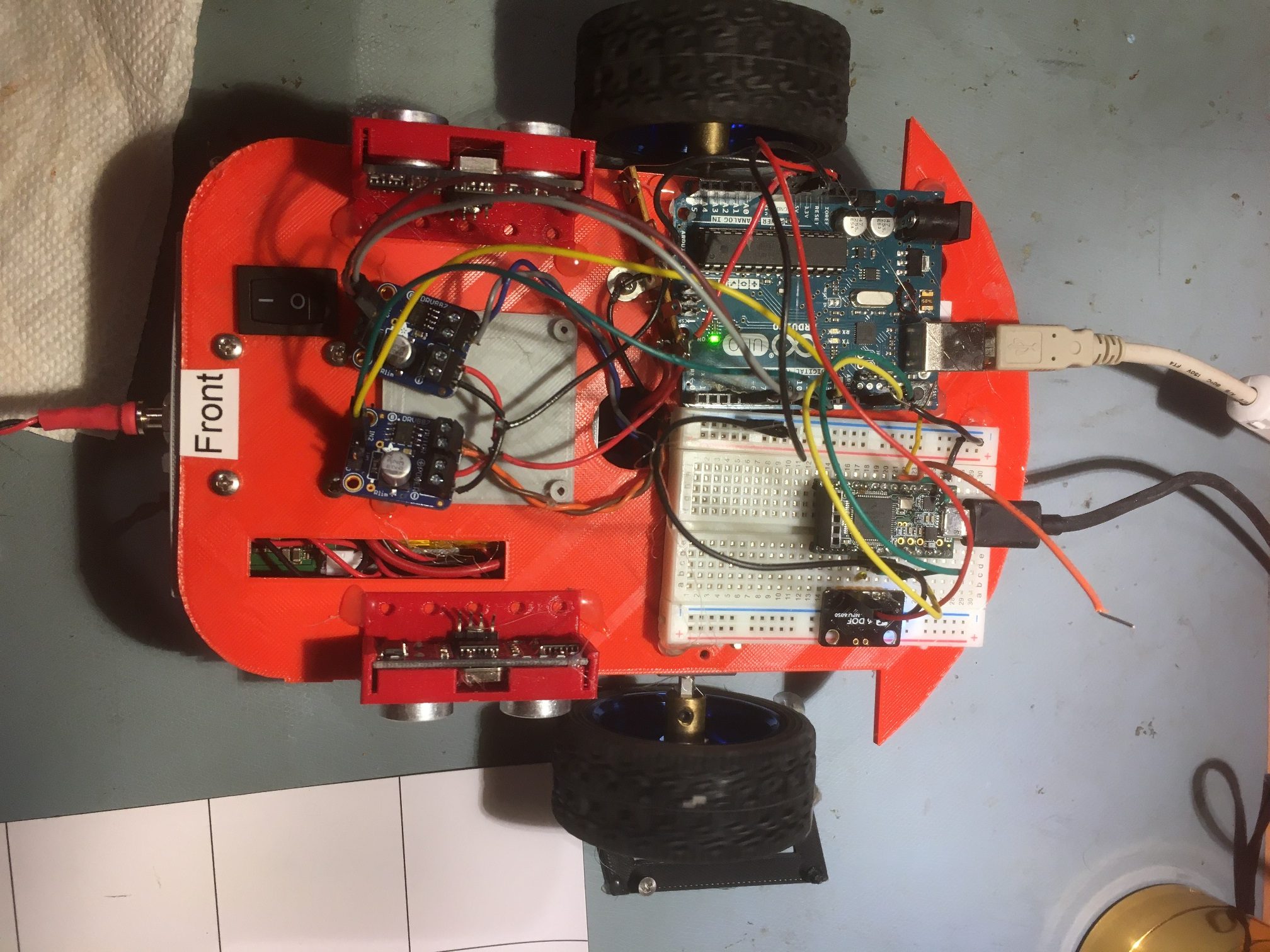

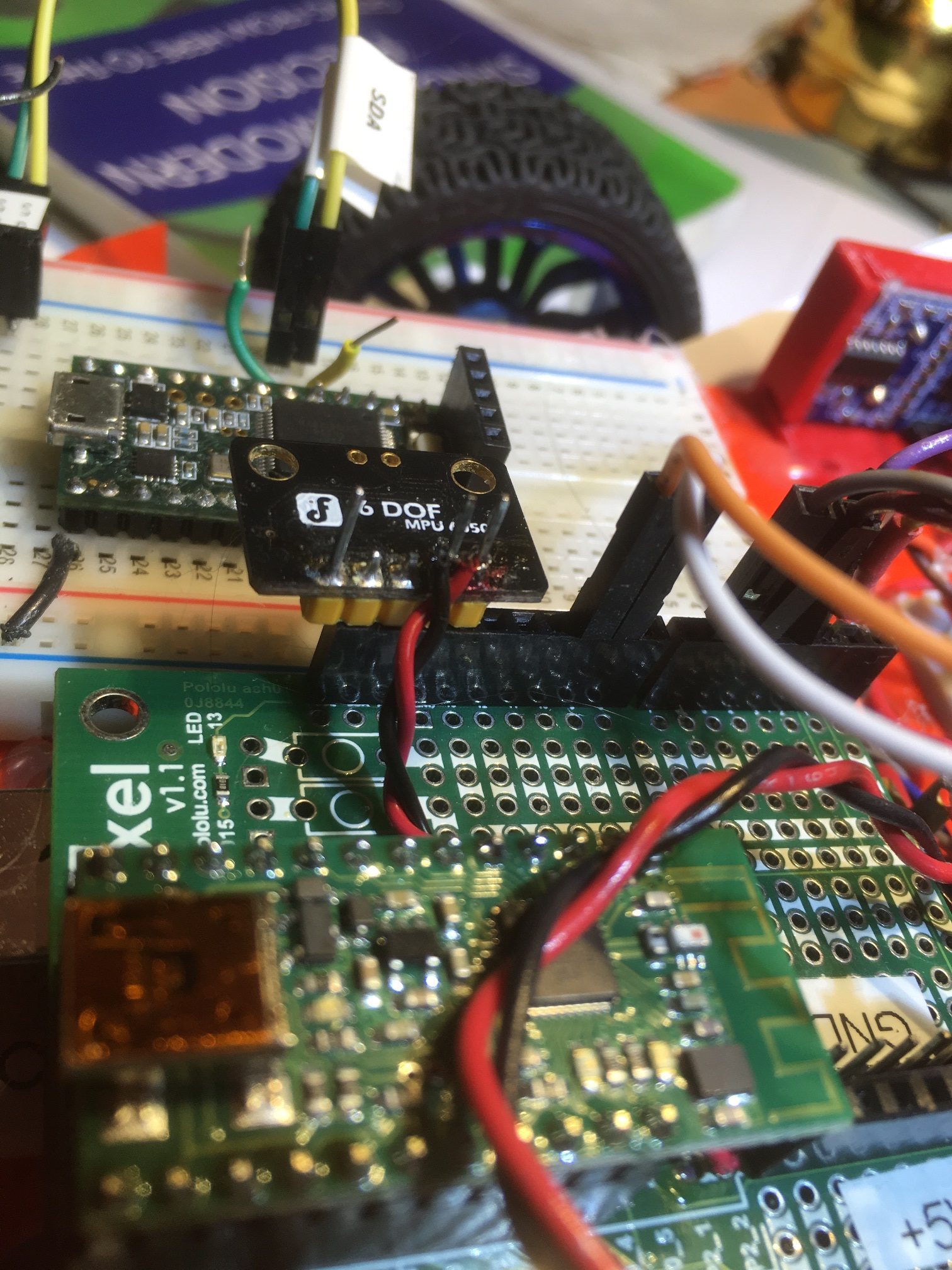

A typical I2C sentence when communicating with a MPU6050 IMU module goes like:

"I2C(68) wrote 1 byte to 75 - C0 Done."

"I2C(68) wrote 3 bytes to 72 - C0 0C 10 Done."

"I2C(68) read 5 bytes from 6A - C0 0C 10 14 03 Done."

To form a sentence, we need:

Device addr: 68 in the above examples

Read/Write direction

To/From register address: 75, 72 and 6A in the above examples

Data: C0, C0 0C 10, and C0 0C 10 14 03 in the above examples

number of bytes written/read: 1,3 & 5 in the above examples

Each I2C communication proceeds as follows (assuming a START from an IDLE condition):

A START or RESTART condition, denoted by SDA & SCL HIGH, followed by SDA LOW, SCL HIGH

A 7-bit device address, MSB first (0x8/0xC = 1, 0x0/0x4 = 0)

A R/W bit (0x8/0xC = read, 0x0/0x4 = write)

An ACK bit (0x8/0xC = NAK, 0x0/0x4 = ACK)

If the bus direction is WRITE, then

A register address for read/write

zero or more additional data bytes

Else (the bus direction is READ)

One or more additional data bytes

Endif

*/

/*

This version adds tonton81's circular buffer class (https://github.com/tonton81/Circular_Buffer)

to simulate real-time processing and display of I2C bus activity. The sample data is loaded into

a FIFO by an ISR triggered every microsecond by a timer, and then the processing code pulls it out

and parses it as fast as possible. If this works, then the next version will eliminate the sample

data and connect to a live I2C bus.

*/

#include <TimerOne.h> //needed for ISR

#include "circular_buffer.h"

Circular_Buffer<uint8_t, 2048> cb_trans; //holds transition values from ISR

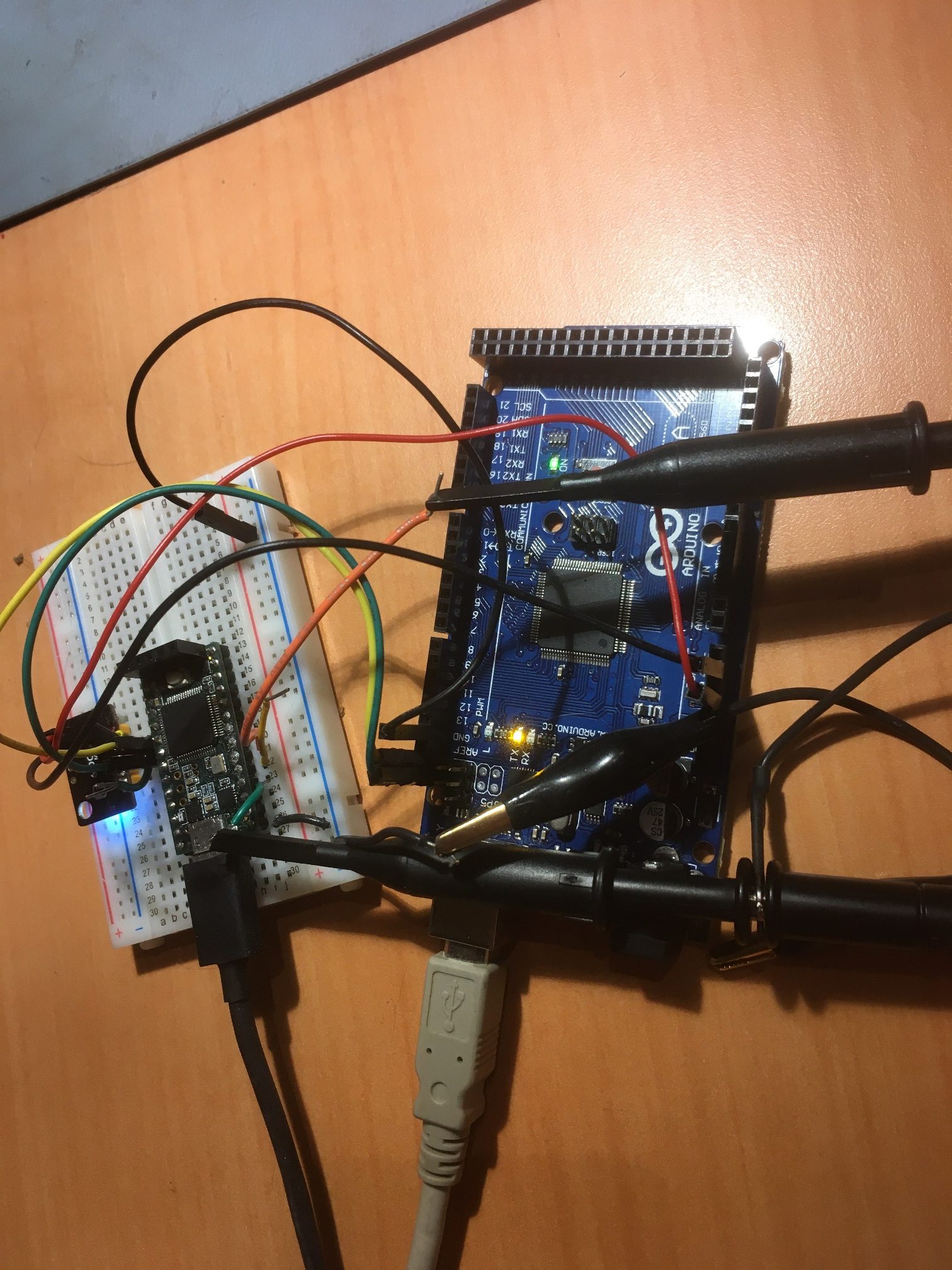

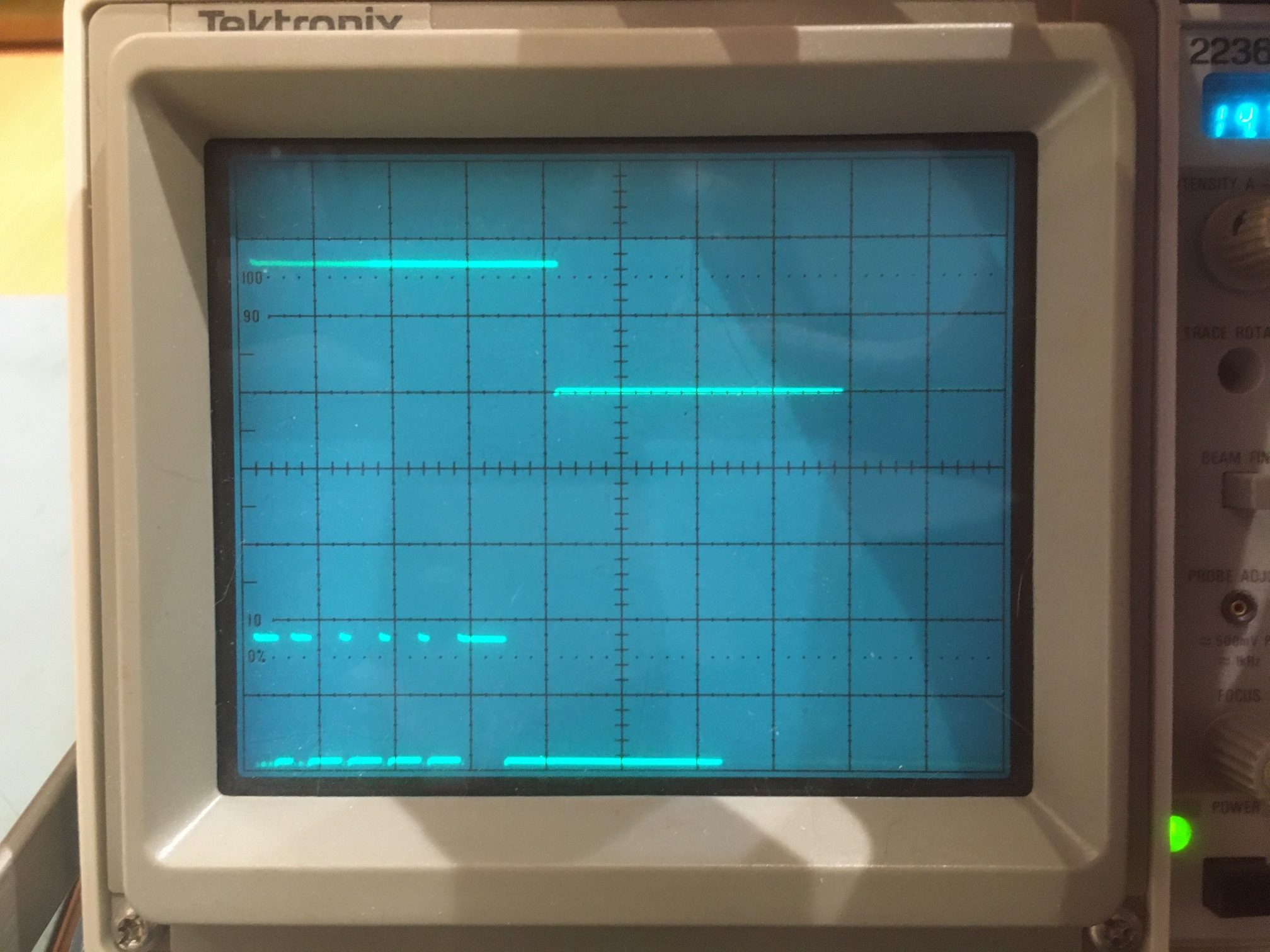

#define MONITOR_OUT1 2 //so can monitor ISR activity with O'scope

#define MONITOR_OUT2 3 //so can monitor ISR activity with O'scope

const int SIM_DATA_ARRAY_SIZE = 928;

byte simdata[SIM_DATA_ARRAY_SIZE] =

{

0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc,

0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0xc,

0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc,

0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0xc,

0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0,

0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0xc, 0x4, 0x8,

0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x8,

0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4,

0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0,

0x4, 0x8, 0xc, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8,

0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8,

0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0xc, 0x4,

0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4,

0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0,

0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4,

0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8,

0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc,

0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc,

0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0xc,

0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0,

0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc,

0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0,

0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4,

0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8,

0xc, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4,

0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4,

0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8,

0xc, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0,

0x4, 0x0, 0x4, 0x8, 0xc, 0x8, 0xc, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x0, 0x4, 0x0, 0x4, 0x8, 0xc, 0x0, 0x4, 0xc, 0x4, 0x8, 0xc, 0x8, 0xc, 0x0,

0x4, 0x8, 0xc, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4, 0x0, 0x4,

0x8, 0xc

};

//#define PARSE_LOOP_DEBUG

//#define GET_8BIT_DATABYTE_DEBUG

const int BUFFER_CHECK_INTERVAL_MSEC = 200;

//const int BUFFER_CHECK_INTERVAL_MSEC = 5;

#pragma region PROCESSING_VARIABLES

uint8_t devAddr;

uint8_t regAddr;

//added for bus direction labels

enum BUSDIR

{

WRITE,

READ,

UNKNOWN = -1

} RWDir;

BUSDIR BusDir = BUSDIR::UNKNOWN;

int ACKNAKFlag; //can be negative

uint8_t databyte_array[2048]; //holds multiple databytes for later output sentence construction

uint16_t databyte_idx = 0; //index into databyte_array

uint16_t numbytes = 0; //number of data bytes extracted from data stream

uint8_t killbuff[2]; //used to consume start/stop bytes

#pragma endregion ProcVars

#pragma region ISR_VARS

uint16_t write_index = 0;

uint16_t read_index = 0;

uint8_t current_portb = 0xFF;

uint8_t last_portb = 0xFF;

bool bBufferFull = false;

elapsedMillis mSecSinceLastBufferCheck;

#pragma endregion ISRVars

int DecodeAndPrintFIFOContents(Circular_Buffer<uint8_t, 2048>& cb); //need forward reference here

//-------------------------------------------------------------------------------

//-------------------------------- ISR ------------------------------------

//-------------------------------------------------------------------------------

//01/04/2020 modified to 'capture' data from simdata[]

void capture_data(void)

{

if (!bBufferFull) //for debug - writes only one set of data to FIFO

{

last_portb = current_portb;

current_portb = simdata[read_index]; //pull one transition value from simdata

read_index++;

if (last_portb != current_portb && !bBufferFull)

{

cb_trans.write(current_portb); //add current transition value to FIFO

digitalWriteFast(MONITOR_OUT1, !digitalReadFast(MONITOR_OUT1));

}

//pause writing to cb_trans circular buffer

if (read_index >= SIM_DATA_ARRAY_SIZE)

{

bBufferFull = true;

read_index = 0;

digitalWriteFast(MONITOR_OUT1, LOW);

}

}

}

void setup()

{

Serial.begin(1); //rate value ignored

unsigned long now = millis();

int idx = 0;

while (!Serial && (millis() - now) < 3000)

{

delay(500);

idx++;

}

Serial.printf("Serial available after %lu mSec\n", millis() - now);

pinMode(MONITOR_OUT1, OUTPUT);

pinMode(MONITOR_OUT2, OUTPUT);

pinMode(LED_BUILTIN, OUTPUT);

Timer1.initialize(1); // run every mico second

Timer1.attachInterrupt(capture_data);

mSecSinceLastBufferCheck = 0;

}

void loop()

{

if (mSecSinceLastBufferCheck > BUFFER_CHECK_INTERVAL_MSEC)

{

Serial.printf("%lu: cb_trans contains = %d elements\n", millis(), cb_trans.size());

mSecSinceLastBufferCheck -= BUFFER_CHECK_INTERVAL_MSEC;

DecodeAndPrintFIFOContents(cb_trans); //decode and print everything captured so far

Serial.printf("%lu: cb_trans contains = %d elements\n", millis(), cb_trans.size());

//cb_trans.clear();

read_index = 0;

bBufferFull = false;

digitalWriteFast(MONITOR_OUT2, !digitalReadFast(MONITOR_OUT2));

while (true)

{

}

}

}

void PrintNextFIFOBytes(Circular_Buffer<uint8_t, 2048>& cb, uint8_t numbytes)

{

Serial.printf("Next %d FIFO Bytes: ", numbytes);

for (uint8_t i = 0; i < numbytes-1; i++)

{

Serial.printf("%x,", cb.peek(i));

}

Serial.printf("%x\n", cb.peek(numbytes-1));

}

bool IsStart(Circular_Buffer<uint8_t, 2048>& cb)

{

bool result = false;

uint8_t data[2]; data[0] = data[1] = 0;

data[0] = cb.peek(0);

data[1] = cb.peek(1);

if (data[0] == 0xC && data[1] == 0x4)

{

//Serial.printf("Start detected at size = %d, data idx = %d\n", cb.size(), SIM_DATA_ARRAY_SIZE - cb.size());

result = true;

}

return result;

}

bool IsStop(Circular_Buffer<uint8_t, 2048>& cb)

{

bool result = false;

uint8_t data[2];

cb.peekBytes(data, 2);

if (data[0] == 0x4 && data[1] == 0xC)

{

//cb.readBytes(data, 2); //consume these bytes

result = true;

}

return result;

}

uint8_t Get7BitDeviceAddr(Circular_Buffer<uint8_t, 2048>& cb)

{

//Purpose: Construct a 7-bit address starting from next FIFO element

//Inputs:

// cb = reference to cb_trans FIFO

//Outputs:

// returns the address as an 8-bit value with the MSB = 0, or 0x0 if unsuccessful

// the 14 transitions associated with the 7-bit address removed from FIFO

//Plan:

// Step1: Convert a pair of FIFO elements into a 0 or 1

// Step2: Add the appropriate value to an ongoing sum

// Step3: return the total.

//Notes:

// A '0' is coded as a 0x0 followed by a 0x4

// A '1' is coded as a 0x8 followed by a 0xC

uint8_t devAddr = 0x0; //failure return value

//devAddr is exactly 7 bits long, so 8 bits with MSB = 0

uint8_t data[2]; //holds one transition pair

for (size_t i = 0; i < 7; i++)

{

cb.readBytes(data, 2);

//data[0] = cb.read();

//data[1] = cb.read();

//Serial.printf("data[0] = %x, data[1] = %x\n", data[0], data[1]);

if (data[0] == 0x8 && data[1] == 0xC)

{

//Serial.printf("Get7BitDeviceAddr: '1' found at i = %d, adding %x to devAddr to get %x\n",

//i, 1 << (7 - i), devAddr + (1 << (7 - i)));

devAddr += (1 << (7 - i)); //add 2^(7-i) to sum

}

}

devAddr = devAddr >> 1; //divide result by 2 to get 7-bit addr from 8 bits

return devAddr;

}

int GetReadWriteFlag(Circular_Buffer<uint8_t, 2048>& cb)

{

//Purpose: decode R/W byte pair

//Inputs:

// cb = reference to cb_trans FIFO

//Outputs:

// readidx = if successful, points to next byte pair in simdata

// returns 1 for Read (0x8/0xC), 0 for Write (0x0/0x4), -1 for failure

//Notes:

//

int result = 0;

uint8_t data[2];

data[0] = cb.read();

data[1] = cb.read();

//Serial.printf("data[0] = %x, data[1] = %x\n", data[0], data[1]);

if (data[0] == 0x8 && data[1] == 0xC)

{

result = 1; //read detected

}

//else if (simdata[readidx] == 0x0 && simdata[readidx + 1] == 0x4)

else if (data[0] == 0x0 && data[1] == 0x4)

{

result = 0; //write detected

}

else

{

result = -1; //failed to detect read or write

}

return result;

}

int GetACKNAKFlag(Circular_Buffer<uint8_t, 2048>& cb)

{

//Purpose: decode ACK/NAK byte pair

//Inputs:

// cb = reference to cb_trans circular buffer holding transition values

//Outputs:

// returns 1 for NAK (0x8/0xC), 0 for ACK (0x0/0x4), -1 for failure

//Notes:

// this code is identical to the code for GetReadWriteFlag, so use it instead

return GetReadWriteFlag(cb_trans);

}

int Get8BitDataByte(Circular_Buffer<uint8_t, 2048>& cb)

{

//Purpose: Construct a 8-bit data byte starting from dataidx

//Inputs:

// cb = reference to cb_trans circular buffer holding transition values

//Outputs:

// returns the address as an 8-bit value, or -1 if unsuccessful

// dataidx = pointer to next simdata entry

//Plan:

// Step1: Convert a pair of simdata entries into a 0 or 1

// Step2: Add the appropriate value to an ongoing sum

// Step3: return the total.

//Notes:

// A '0' is coded as a 0x0 followed by a 0x4

// A '1' is coded as a 0x8 followed by a 0xC

// 12/29/19 - changed return val to int, so can return -1 when a 'short byte' is detected

int dataval = 0x0;

int numbits = 0;

uint8_t data[2]{ 0x0,0x0 }; //holds one transition pair

////DEBUG!!

// Serial.printf("Get8BitDataByte top: data[0] = %x,data[1] = %x, size = %d, idx = %d\n",

// data[0], data[1], cb.size(), SIM_DATA_ARRAY_SIZE - cb.size());

// PrintNextFIFOBytes(cb, 20);

////DEBUG!!

//8 bits with MSB = 0

for (size_t i = 0; i < 8; i++)

{

data[0] = cb.peek(0); data[1] = cb.peek(1);

//Serial.printf("data[0] = %x, data[1] = %x\n", data[0], data[1]);

if (data[0] == 0x0 && data[1] == 0x4)

{

cb.readBytes(data, 2);// now consume the bytes

numbits++;

}

else if (data[0] == 0x8 && data[1] == 0xC)

{

#ifdef GET_8BIT_DATABYTE_DEBUG

Serial.printf("Get8BitDataByte: '1' found at i = %d, adding %x to devAddr to get %x\n",

i, 1 << (7 - i), dataval + (1 << (7 - i)));

#endif

cb.readBytes(data, 2);// now consume the bytes

dataval += (1 << (7 - i)); //add 2^(8-i) to sum

numbits++;

}

else //not a 1 or 0 - get me outa here!

{

break;

}

}

////DEBUG!!

// Serial.printf("Get8BitDataByte bottom: numbits = %d, data[0] = %x,data[1] = %x, size = %d, idx = %d\n",

// numbits, data[0], data[1], cb.size(), SIM_DATA_ARRAY_SIZE - cb.size());

// PrintNextFIFOBytes(cb, 20);

////DEBUG!!

if (numbits != 8)

{

dataval = -1; //error return value

}

return dataval;

}

int GetDataBytes(Circular_Buffer<uint8_t, 2048>& cb, uint8_t* databytes)

{

//Notes:

// 01/01/2020: removed databyteidx from sig - always starts at zero

uint16_t numbytes = 0;

uint16_t databyte_idx = 0;

bool StartFlag = false;

bool StopFlag = false;

int dataval;

do

{

dataval = Get8BitDataByte(cb);

////DEBUG!!

// Serial.printf("GetDataBytes() just after Get8BitDataByte(): datval = %x, size = %d, idx = %d\n",

// dataval, cb.size(), SIM_DATA_ARRAY_SIZE-cb.size());

// PrintNextFIFOBytes(cb, 10);

////DEBUG!!

//watch out for 'short byte' reads

if (dataval >= 0)

{

uint8_t databyte = (uint8_t)dataval;

databyte_array[databyte_idx] = databyte;

databyte_idx++;

numbytes++;

ACKNAKFlag = GetACKNAKFlag(cb_trans); //01/05/20 moved inside 'good byte' block

}

//ACKNAKFlag = GetACKNAKFlag(cb_trans);

////DEBUG!!

// Serial.printf("GetDataBytes() just after GetACKNAKFlag(): ACKNAK = %d, size = %d, idx = %d\n",

// ACKNAKFlag, cb.size(), SIM_DATA_ARRAY_SIZE-cb.size());

// PrintNextFIFOBytes(cb, 10);

////DEBUG!!

StartFlag = IsStart(cb_trans);

////DEBUG!!

// Serial.printf("GetDataBytes() just after IsStart(): StartFlag = %d, size = %d, idx = %d\n",

// StartFlag, cb.size(), SIM_DATA_ARRAY_SIZE-cb.size());

// PrintNextFIFOBytes(cb, 10);

////DEBUG!!

StopFlag = IsStop(cb_trans);

#ifdef PARSE_LOOP_DEBUG

Serial.printf("IsStart %d, IsStop %d, next two bytes are %x, %x, data idx = %d\n",

StartFlag, StopFlag, cb.peek(0), cb.peek(1), SIM_DATA_ARRAY_SIZE-cb.size());

#endif

} while (!StartFlag && !StopFlag && cb_trans.size() > 0);

return numbytes;

}

void OutputFormattedSentence(int RW, uint8_t dev, uint8_t reg, uint8_t numbytes, uint8_t* bytearray, uint16_t startidx)

{

Serial.printf("I2C(%x) %s %d bytes %s %x... ",

dev, (RW == 0 ? "writing" : "reading"), numbytes - startidx, (RW == 0 ? "to" : "from"), reg);

for (size_t i = startidx; i < numbytes; i++)

{

Serial.printf("%x ", bytearray[i]);

}

Serial.printf(". Done\n");

}

int DecodeAndPrintFIFOContents(Circular_Buffer<uint8_t, 2048>& cb)

{

//Purpose: decode and print I2C conversation held in cb_trans FIFO

//Inputs:

// cb = 2048 element FIFO

//Outputs:

// returns number of bytes processed, or -1 for failure

// outputs structured I2C sentence to serial monitor

//Plan:

// Step1: Determine if there is anything to do (have to have more than one transition in FIFO)

// Step2: Parse transitions into I2C sentence structure

// Step3: Output sentence to serial monitor

if (cb.size() < 2)

{

return 0;

}

while (cb.size() > 0)

{

#ifdef PARSE_LOOP_DEBUG

Serial.printf("At top of while (cb.size() > 0): size = %d\n", cb.size());

Serial.printf("Next two bytes in FIFO are %x, %x\n", cb.peek(0), cb.peek(1));

#endif

//Find a START sequence (0xC followed by 0x4)

while (!IsStart(cb))

{

Serial.printf("looking for start...\n");

}

cb.readBytes(killbuff,2); //01/05/20 moved START byte consume out of IsStart()

#ifdef PARSE_LOOP_DEBUG

Serial.printf("Start sequence found, FIFO size = %d, idx = %d\n", cb.size(), SIM_DATA_ARRAY_SIZE-cb.size());

//PrintNextFIFOBytes(cb_trans, 20);

#endif

if (cb.size() > 14)//14 entries required for 7-bit address

{

//Get 7-bit device address

devAddr = Get7BitDeviceAddr(cb);

//Serial.printf("devAddr = %x, FIFO size = %d, idx = %d\n", devAddr, cb.size(), SIM_DATA_ARRAY_SIZE - cb.size());

}

//get read/write flag 1 = Read, 0 = Write, -1 = error

BusDir = (BUSDIR)GetReadWriteFlag(cb);

#ifdef PARSE_LOOP_DEBUG

Serial.printf("BusDir = %s\n", ((BusDir == BUSDIR::WRITE) ? "WRITE" : "READ"));

//PrintNextFIFOBytes(cb_trans, 20);

#endif

//get ACK/NAK flag

ACKNAKFlag = GetACKNAKFlag(cb);

numbytes = GetDataBytes(cb, databyte_array); //terminates on a START, but the start bytes are not consumed

#ifdef PARSE_LOOP_DEBUG

Serial.printf("Got %d bytes from GetDataBytes() --> ", numbytes);

for (size_t i = 0; i < numbytes; i++)

{

Serial.printf(" %x ", databyte_array[i]);

}

Serial.printf("\n");

//PrintNextFIFOBytes(cb_trans, 20);

#endif

//If the bus direction is WRITE, then extract

// A register address for read / write

// zero or more additional data bytes

if (BusDir == BUSDIR::WRITE)

{

regAddr = databyte_array[0];

#ifdef PARSE_LOOP_DEBUG

Serial.printf("regAddr = %x, cb size = %d\n", regAddr, cb.size());

#endif

//check for additional data

if (numbytes > 1)

{

#ifdef PARSE_LOOP_DEBUG

Serial.printf("Additional data found!\n");

for (size_t i = 0; i < numbytes; i++)

{

Serial.printf("data[%d] = %x\n", i, databyte_array[i]);

}

#endif

//1st byte is register addr, subsequent bytes are data

OutputFormattedSentence(BusDir, devAddr, regAddr, numbytes, databyte_array, 1);

}

}

else //all bytes are data

{

#ifdef PARSE_LOOP_DEBUG

Serial.printf("In data block: got %d bytes of data\n", numbytes);

for (size_t i = 0; i < numbytes; i++)

{

Serial.printf("data[%d] = %x\n", i, databyte_array[i]);

}

#endif

OutputFormattedSentence(BusDir, devAddr, regAddr, numbytes, databyte_array, 0);

}

#ifdef PARSE_LOOP_DEBUG

Serial.printf("At end of while (cb.size() > 0): size = %d\n", cb.size());

Serial.printf("Next two bytes in FIFO are %x, %x\n", cb.peek(0), cb.peek(1));

#endif

}//while (cb.size() > 0)

return 1;

}