Posted 22 January 2023

This post is intended to get me synched back up with the current state of play in my numerous wall track tuning exercises. I am using these posts as a memory aid, as my short-term memory sucks these days.

Difference between WallE3_WallTrackTuning_V5 & _V4:

- V5 uses ‘enums.h’ to eliminate VS2022 intellisense errors

- V5 RotateToParallelOrientation(): ported in from WallE3_ParallelFind_V1

- V5 MoveToDesiredLeftDistCm uses Left distance corrected for orientation, but didn’t make change from uint16_t to float (fixed 01/22/23)

- V5 changed parameter input from Offset, Kp,Ki,Kd to Offset, RunMsec, LoopMsec

- V5 modified to try ‘pulsed turn’ algorithm.

Difference between WallE3_WallTrackTuning_V4 & _V3:

- V4 added #define NO_LIDAR

- V4 changed distance sensor values from uint16_t to float

- V4 experimented with ‘flip-flopping’ WallTrackSetPoint from -0.2 to +0.2 dep on how close the corrected center distance was to the desired offset (However, I believe this was done incorrectly – the PID engine compared the corrected center distance to WallTrackSetPoint – literally apples to oranges)

So WallE3_WallTrackTuning_V5 seems to be the latest ‘tuning’ implementation.

Comparison of WallE3_WallTrack_Vx files:

WallE3_WallTrack_V2 vs WallE3_WallTrack_V1 (Created: 2/19/2022)

- V2 moved all inline tracking code into TrackLeft/RightWallOffset() functions (later ported back into V1 – don’t know why)

- V2 changed all ‘double’ declarations to ‘float’ due to change from Mega2560 to T3.5

WallE3_WallTrack_V3 vs WallE3_WallTrack_V2 (Created: 2/22/2022)

- V3 Chg left/right/rear dists from mm to cm

- V3 Concentrated all environmental updates into UpdateAllEnvironmentParameters();

- V3 No longer using GetOpMode()

WallE3_WallTrack_V4 vs WallE3_WallTrack_V3 (Created: 3/25/2022)

- V4 Added ‘RollingForwardTurn() function

WallE3_WallTrack_V5 vs WallE3_WallTrack_V4 (Created: 3/25/2022)

- No real changes between V5 & V4

24 January 2023 Update:

I returned WallE3_WallTrackTuning_V5 to its original configuration, using my custom PIDCalcs() function, using the following modified inputs:

|

1 2 3 4 |

//from Teensy_7VL53L0X_I2C_Slave_V3.ino: LeftSteeringVal = (LF_Dist_mm - LR_Dist_mm) / 100.f; //rev 06/21/20 see PPalace post glLeftCentCorrCm = CorrDistForOrient(glLeftCenterCm, glLeftSteeringVal); float offset_factor = (glLeftCentCorrCm - OffCm) / 10.f; WallTrackSteerVal = glLeftSteeringVal + offset_factor; |

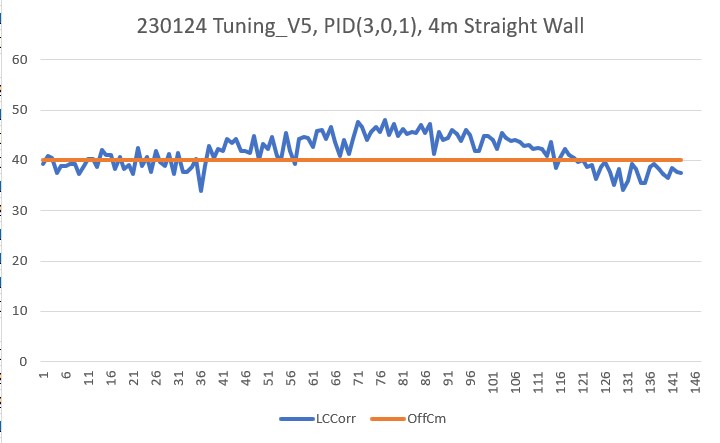

So this is the ‘other’ method – using the modified steering value as the input, and trying to drive the system to zero. Within just a few trials I rapidly homed in on one of the PID triplets I had used before, namely PID(3,0,1). Here’s the raw output, a plot of orientation-corrected distance vs setpoint, and a short video on my 4m straight wall section:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 |

TrackLeftWallOffset: Start tracking offset of 40.0 cm with Kp/Ki/Kd = 3.00 0.00 1.00 Msec LF LC LR Steer Deg Cos LCCorr Set Err SpinDeg In TrackLeftWallOffset: before while with errcode = NO_ANOMALIES Msec LF LC LR LCCorr OffCm tErr LastI LastD Out Lspd Rspd 28916 40.10 40.30 38.80 39.21 40.00 0.79 0.00 0.79 1.58 76 73 28966 39.20 41.90 38.00 40.93 40.00 -0.93 0.00 -1.72 -1.07 73 76 29016 40.10 41.40 38.00 40.44 40.00 -0.44 0.00 0.49 -1.82 73 76 29066 40.10 41.40 37.60 37.48 40.00 2.52 0.00 2.97 4.60 79 70 29116 39.90 41.70 37.80 38.85 40.00 1.15 0.00 -1.37 4.82 79 70 29166 39.80 41.70 37.70 38.85 40.00 1.15 0.00 0.00 3.44 78 71 29216 39.60 41.10 37.90 39.23 40.00 0.77 0.00 -0.38 2.69 77 72 29266 39.90 41.80 37.90 39.20 40.00 0.80 0.00 0.03 2.38 77 72 29316 39.90 41.60 37.30 37.36 40.00 2.64 0.00 1.84 6.08 81 68 29366 40.10 42.10 37.90 38.96 40.00 1.04 0.00 -1.60 4.72 79 70 29416 40.10 41.70 38.60 40.21 40.00 -0.21 0.00 -1.25 0.62 75 74 29466 40.10 41.70 38.60 40.21 40.00 -0.21 0.00 0.00 -0.63 74 75 29516 41.10 41.80 38.90 38.68 40.00 1.32 0.00 1.53 2.43 77 72 29566 39.90 42.30 39.40 42.13 40.00 -2.13 0.00 -3.45 -2.94 72 77 29616 40.20 42.00 39.10 41.18 40.00 -1.18 0.00 0.95 -4.49 70 79 29666 40.00 42.80 38.40 41.07 40.00 -1.07 0.00 0.12 -3.31 71 78 29716 41.40 42.60 38.80 38.26 40.00 1.74 0.00 2.81 2.42 77 72 29766 40.10 41.90 38.80 40.77 40.00 -0.77 0.00 -2.51 0.21 75 74 29816 41.20 42.10 38.80 38.40 40.00 1.60 0.00 2.36 2.43 77 72 29866 41.30 42.90 38.80 39.13 40.00 0.87 0.00 -0.73 3.33 78 71 29916 41.30 42.90 38.30 37.22 40.00 2.78 0.00 1.91 6.42 81 68 29966 40.50 43.10 39.60 42.54 40.00 -2.54 0.00 -5.31 -2.30 72 77 30016 41.30 42.10 39.10 38.96 40.00 1.04 0.00 3.58 -0.46 74 75 30066 40.80 43.20 38.90 40.76 40.00 -0.76 0.00 -1.80 -0.48 74 75 30116 41.80 42.60 39.00 37.63 40.00 2.37 0.00 3.14 3.98 78 71 30166 41.20 43.00 39.90 41.84 40.00 -1.84 0.00 -4.21 -1.30 73 76 30216 41.40 43.80 38.90 39.65 40.00 0.35 0.00 2.19 -1.14 73 76 30266 41.50 44.40 38.60 38.87 40.00 1.13 0.00 0.77 2.60 77 72 30316 40.80 42.20 39.60 41.23 40.00 -1.23 0.00 -2.35 -1.32 73 76 30366 40.80 42.70 37.90 37.39 40.00 2.61 0.00 3.84 4.00 79 70 30416 40.90 43.30 39.30 41.55 40.00 -1.55 0.00 -4.16 -0.48 74 75 30466 41.30 43.50 38.30 37.74 40.00 2.26 0.00 3.80 2.97 77 72 30516 40.80 42.60 38.00 37.63 40.00 2.37 0.00 0.12 7.00 82 67 30566 40.80 42.80 38.30 38.74 40.00 1.26 0.00 -1.12 4.88 79 70 30616 40.30 42.60 38.40 40.20 40.00 -0.20 0.00 -1.45 0.86 75 74 30666 40.90 42.30 38.40 33.83 40.00 6.17 0.00 6.37 12.15 87 62 30716 41.90 44.00 39.10 38.86 40.00 1.14 0.00 -5.04 8.45 83 66 30766 41.60 44.20 40.20 42.82 40.00 -2.82 0.00 -3.96 -4.50 70 79 30816 41.50 44.00 39.20 40.43 40.00 -0.43 0.00 2.39 -3.68 71 78 30866 41.80 43.60 40.40 42.24 40.00 -2.24 0.00 -1.81 -4.91 70 79 30916 41.90 43.50 40.40 41.94 40.00 -1.94 0.00 0.29 -6.13 68 81 30966 41.70 44.40 41.40 44.33 40.00 -4.33 0.00 -2.39 -10.61 64 85 31016 41.50 44.40 40.30 43.37 40.00 -3.37 0.00 0.96 -11.08 63 86 31066 42.00 44.70 41.20 44.24 40.00 -4.24 0.00 -0.86 -11.85 63 86 31116 42.40 45.20 40.20 41.83 40.00 -1.83 0.00 2.41 -7.89 67 82 31166 42.70 44.40 40.80 41.89 40.00 -1.89 0.00 -0.07 -5.62 69 80 31216 42.40 44.90 40.20 41.55 40.00 -1.55 0.00 0.34 -5.00 70 79 31266 41.80 46.70 40.20 44.81 40.00 -4.81 0.00 -3.26 -11.17 63 86 31316 43.00 47.00 39.80 40.02 40.00 -0.02 0.00 4.79 -4.85 70 79 31366 42.80 44.90 41.30 43.29 40.00 -3.29 0.00 -3.27 -6.61 68 81 31416 42.60 46.40 40.20 42.33 40.00 -2.33 0.00 0.97 -7.95 67 82 31466 42.40 45.00 41.80 44.74 40.00 -4.74 0.00 -2.41 -11.80 63 86 31516 42.90 44.60 40.60 40.98 40.00 -0.98 0.00 3.75 -6.70 68 81 31566 43.50 45.00 40.80 40.08 40.00 -0.08 0.00 0.90 -1.15 73 76 31616 43.00 46.60 41.80 45.52 40.00 -5.52 0.00 -5.44 -11.13 63 86 31666 43.40 45.80 41.00 41.78 40.00 -1.78 0.00 3.75 -9.08 65 84 31716 43.30 45.60 40.20 39.20 40.00 0.80 0.00 2.58 -0.18 74 75 31766 42.90 45.60 41.50 44.18 40.00 -4.18 0.00 -4.97 -7.55 67 82 31816 42.80 45.70 41.60 44.64 40.00 -4.64 0.00 -0.47 -13.46 61 88 31866 43.30 46.50 41.60 44.38 40.00 -4.38 0.00 0.26 -13.41 61 88 31916 43.50 46.20 41.30 42.75 40.00 -2.75 0.00 1.63 -9.89 65 84 31966 43.70 45.80 42.70 45.79 40.00 -5.79 0.00 -3.04 -14.34 60 89 32016 43.30 46.70 42.40 46.09 40.00 -6.09 0.00 -0.30 -17.97 57 92 32066 43.40 46.40 41.70 44.29 40.00 -4.29 0.00 1.80 -14.66 60 89 32116 43.50 47.30 42.60 46.68 40.00 -6.68 0.00 -2.39 -17.65 57 92 32166 44.90 46.90 42.80 43.70 40.00 -3.70 0.00 2.98 -14.07 60 89 32216 44.70 47.10 41.70 40.87 40.00 -0.87 0.00 2.83 -5.43 69 80 32266 44.30 46.60 42.40 43.97 40.00 -3.97 0.00 -3.10 -8.81 66 83 32316 45.00 47.60 42.00 41.30 40.00 -1.30 0.00 2.67 -6.57 68 81 32366 45.20 47.30 43.20 44.36 40.00 -4.36 0.00 -3.05 -10.01 64 85 32416 44.40 48.10 43.70 47.72 40.00 -7.72 0.00 -3.36 -19.79 55 94 32466 44.50 46.90 43.90 46.63 40.00 -6.63 0.00 1.09 -20.97 54 95 32516 45.60 48.00 43.30 44.11 40.00 -4.11 0.00 2.52 -14.84 60 89 32566 45.10 47.50 43.50 45.58 40.00 -5.58 0.00 -1.47 -15.26 59 90 32616 44.60 48.00 43.30 46.70 40.00 -6.70 0.00 -1.13 -18.98 56 93 32666 45.10 48.30 43.20 45.57 40.00 -5.57 0.00 1.13 -17.85 57 92 32716 44.10 48.20 43.60 48.00 40.00 -8.00 0.00 -2.43 -21.58 53 96 32766 45.40 47.40 43.60 44.99 40.00 -4.99 0.00 3.02 -17.98 57 92 32816 44.30 47.50 43.70 47.22 40.00 -7.22 0.00 -2.23 -19.43 55 94 32866 44.80 47.90 42.80 44.92 40.00 -4.92 0.00 2.30 -17.06 57 92 32916 44.50 47.40 43.30 46.30 40.00 -6.30 0.00 -1.39 -17.53 57 92 32966 45.20 46.70 43.60 45.24 40.00 -5.24 0.00 1.06 -16.79 58 91 33016 43.60 47.40 42.10 45.71 40.00 -5.71 0.00 -0.46 -16.65 58 91 33066 44.20 47.30 42.60 45.38 40.00 -5.38 0.00 0.32 -16.47 58 91 33116 44.10 47.40 43.50 47.12 40.00 -7.12 0.00 -1.74 -19.63 55 94 33166 44.20 47.10 42.70 45.42 40.00 -5.42 0.00 1.71 -17.96 57 92 33216 43.40 47.80 42.50 47.17 40.00 -7.17 0.00 -1.76 -19.76 55 94 33266 44.50 47.20 41.60 41.33 40.00 -1.33 0.00 5.85 -9.83 65 84 33316 43.20 46.60 42.10 45.69 40.00 -5.69 0.00 -4.37 -12.71 62 87 33366 44.30 46.60 42.60 43.97 40.00 -3.97 0.00 1.72 -13.63 61 88 33416 43.80 45.80 42.50 44.56 40.00 -4.56 0.00 -0.59 -13.09 61 88 33466 43.50 46.50 42.80 46.13 40.00 -6.13 0.00 -1.57 -16.82 58 91 33516 43.50 45.80 42.60 45.20 40.00 -5.20 0.00 0.93 -16.53 58 91 33566 43.30 45.70 41.70 43.85 40.00 -3.85 0.00 1.35 -12.90 62 87 33616 42.40 46.10 42.00 45.98 40.00 -5.98 0.00 -2.13 -15.81 59 90 33666 43.10 46.00 42.00 45.10 40.00 -5.10 0.00 0.88 -16.19 58 91 33716 42.60 45.30 40.40 41.92 40.00 -1.92 0.00 3.18 -8.95 66 83 33766 42.60 45.30 40.40 41.92 40.00 -1.92 0.00 0.00 -5.76 69 80 33816 42.30 46.40 40.90 44.95 40.00 -4.95 0.00 -3.03 -11.82 63 86 33866 42.30 46.40 40.90 44.95 40.00 -4.95 0.00 0.00 -14.85 60 89 33916 42.30 44.20 41.90 44.08 40.00 -4.08 0.00 0.87 -13.12 61 88 33966 42.40 44.10 40.80 42.31 40.00 -2.31 0.00 1.77 -8.71 66 83 34016 41.50 45.50 41.10 45.43 40.00 -5.43 0.00 -3.12 -13.18 61 88 34066 41.50 44.50 41.40 44.49 40.00 -4.49 0.00 0.94 -14.42 60 89 34116 41.20 44.40 40.30 43.82 40.00 -3.82 0.00 0.67 -12.13 62 87 34166 40.70 44.10 40.40 44.04 40.00 -4.04 0.00 -0.22 -11.89 63 86 34216 40.40 43.90 39.90 43.72 40.00 -3.72 0.00 0.31 -11.48 63 86 34266 40.20 43.10 39.60 42.85 40.00 -2.85 0.00 0.87 -9.42 65 84 34316 40.00 43.10 40.00 43.10 40.00 -3.10 0.00 -0.25 -9.05 65 84 34366 40.30 43.20 39.10 42.20 40.00 -2.20 0.00 0.90 -7.50 67 82 34416 40.30 43.40 39.20 42.56 40.00 -2.56 0.00 -0.35 -7.31 67 82 34466 39.80 42.90 38.90 42.34 40.00 -2.34 0.00 0.22 -7.23 67 82 34516 39.20 42.40 37.70 40.88 40.00 -0.88 0.00 1.45 -4.11 70 79 34566 38.70 43.70 38.40 43.64 40.00 -3.64 0.00 -2.75 -8.16 66 83 34616 40.00 42.20 37.60 38.49 40.00 1.51 0.00 5.14 -0.62 74 75 34666 39.30 41.30 38.20 40.50 40.00 -0.50 0.00 -2.00 0.51 75 74 34716 38.40 42.80 37.50 42.24 40.00 -2.24 0.00 -1.74 -4.97 70 79 34766 37.90 41.80 36.90 41.13 40.00 -1.13 0.00 1.11 -4.49 70 79 34816 37.70 42.20 36.10 40.49 40.00 -0.49 0.00 0.64 -2.11 72 77 34866 37.70 41.40 36.10 39.72 40.00 0.28 0.00 0.77 0.07 75 74 34916 37.50 41.10 36.30 40.15 40.00 -0.15 0.00 -0.43 -0.02 74 75 34966 37.20 40.70 35.40 38.63 40.00 1.37 0.00 1.52 2.59 77 72 35016 37.00 39.20 37.20 39.17 40.00 0.83 0.00 -0.54 3.02 78 71 35066 37.40 40.10 34.90 36.30 40.00 3.70 0.00 2.87 8.23 83 66 35116 36.40 39.20 35.50 38.69 40.00 1.31 0.00 -2.39 6.33 81 68 35166 36.60 40.70 35.40 39.76 40.00 0.24 0.00 -1.07 1.79 76 73 35216 35.60 37.90 36.10 37.75 40.00 2.25 0.00 2.01 4.75 79 70 35266 37.10 39.80 34.30 35.15 40.00 4.85 0.00 2.59 11.95 86 63 35316 37.00 40.00 35.40 38.38 40.00 1.62 0.00 -3.23 8.09 83 66 35366 37.90 39.40 34.90 34.19 40.00 5.81 0.00 4.19 13.25 88 61 35416 37.70 41.00 34.80 35.90 40.00 4.10 0.00 -1.71 14.02 89 60 35466 37.00 41.10 35.30 39.23 40.00 0.77 0.00 -3.33 5.65 80 69 35516 37.40 40.40 35.60 38.34 40.00 1.66 0.00 0.88 4.08 79 70 35566 37.40 40.20 34.60 35.51 40.00 4.49 0.00 2.84 10.64 85 64 35616 37.40 40.20 34.60 35.51 40.00 4.49 0.00 0.00 13.48 88 61 35666 37.00 39.60 35.80 38.69 40.00 1.31 0.00 -3.18 7.12 82 67 35716 37.10 40.70 35.60 39.25 40.00 0.75 0.00 -0.56 2.82 77 72 35766 37.70 40.30 35.90 38.25 40.00 1.75 0.00 1.00 4.26 79 70 35816 37.10 40.50 34.80 37.22 40.00 2.78 0.00 1.03 7.32 82 67 35866 37.10 39.80 34.80 36.57 40.00 3.43 0.00 0.64 9.64 84 65 35916 36.80 39.50 35.60 38.59 40.00 1.41 0.00 -2.01 6.25 81 68 35966 37.20 40.70 35.00 37.66 40.00 2.34 0.00 0.92 6.08 81 68 36016 36.80 40.50 35.00 37.48 40.00 2.52 0.00 0.19 7.38 82 67 |

So, the ‘steering value tweaked by offset error’ method works on a straight wall with a PID of (3,0,1). This result is consistent with my 11 January 2023 Update of my ‘WallE3 Wall Tracking Revisited‘ post, which I think was done with WallE3_WallTrackTuning_V5 (too many changes for my poor brain to follow).

Unfortunately, as soon as I put breaks in the wall, the robot could no longer follow it. It runs into the same problems; the robot senses a significant change in distance, starts to turn to minimize the distance, but the distance continues to go in the wrong direction due to the change in the robot’s orientation. This feedback continues until the robot is completely orthogonal to the wall.

26 January 2023 Update:

I went back and reviewed the post that contained the successful 30 October 2022 ‘two 30deg wall breaks’ run, and found that the run was made with the following wall following code:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 |

{ digitalToggle(RED_LASER_DIODE_PIN); //10/24/22 toggle duration measurement pulse mSecSinceLastWallTrackUpdate -= WALL_TRACK_UPDATE_INTERVAL_MSEC; //03/08/22 abstracted these calls to UpdateAllEnvironmentParameters() UpdateAllEnvironmentParameters();//03/08/22 added to consolidate sensor update calls //from Teensy_7VL53L0X_I2C_Slave_V3.ino: LeftSteeringVal = (LF_Dist_mm - LR_Dist_mm) / 100.f; //rev 06/21/20 see PPalace post float orientdeg = GetWallOrientDeg(glLeftSteeringVal); float orientrad = (PI / 180.f) * orientdeg; float orientcos = cosf(orientrad); glLeftCentCorrCm = glLeftCenterCm * orientcos; if (!isnan(glLeftCentCorrCm)) { //gl_pSerPort->printf("just before PIDCalcs call: WallTrackSetPoint = %2.2f\n", WallTrackSetPoint); WallTrackOutput = PIDCalcs(glLeftCentCorrCm, WallTrackSetPoint, lastError, lastInput, lastIval, lastDerror, kp, ki, kd); //04/05/22 have to use local var here, as result could be negative int16_t leftSpdnum = MOTOR_SPEED_QTR + WallTrackOutput; int16_t rightSpdnum = MOTOR_SPEED_QTR - WallTrackOutput; //04/05/22 Left/rightSpdnum can be negative here - watch out! rightSpdnum = (rightSpdnum <= MOTOR_SPEED_HALF) ? rightSpdnum : MOTOR_SPEED_HALF; //result can still be neg glRightspeednum = (rightSpdnum > 0) ? rightSpdnum : 0; //result here must be positive leftSpdnum = (leftSpdnum <= MOTOR_SPEED_HALF) ? leftSpdnum : MOTOR_SPEED_HALF;//result can still be neg glLeftspeednum = (leftSpdnum > 0) ? leftSpdnum : 0; //result here must be positive MoveAhead(glLeftspeednum, glRightspeednum); gl_pSerPort->printf(WallFollowTelemStr, millis(), glLeftFrontCm, glLeftCenterCm, glLeftRearCm, glLeftSteeringVal, orientdeg, orientcos, glLeftCentCorrCm, WallTrackSetPoint, lastError, WallTrackOutput, glLeftspeednum, glRightspeednum); } digitalToggle(RED_LASER_DIODE_PIN); //10/24/22 toggle duration measurement pulse |

As can be seen from the above, the line

|

1 2 |

WallTrackOutput = PIDCalcs(glLeftCentCorrCm, WallTrackSetPoint, lastError, lastInput, lastIval, lastDerror, kp, ki, kd); |

Compares the orientation-corrected wall distance to the desired offset distance, as opposed to comparing the computed steering value to a desired steering value of zero, with a ‘fudge factor’ of the distance error divided by 10 as shown below:

|

1 2 3 4 |

//from Teensy_7VL53L0X_I2C_Slave_V3.ino: LeftSteeringVal = (LF_Dist_mm - LR_Dist_mm) / 100.f; //rev 06/21/20 see PPalace post glLeftCentCorrCm = CorrDistForOrient(glLeftCenterCm, glLeftSteeringVal); float offset_factor = (glLeftCentCorrCm - OffCm) / 10.f; WallTrackSteerVal = glLeftSteeringVal + offset_factor; |

So, I modified WallE3_WallTrackTuning_V5 to use the above algorithm to see if I could reproduce the successful ‘two breaks’ tracking run.

Well, the answer was “NO” – I couldn’t reproduce the successful ‘two breaks’ tracking run – not even close – grrr!!

So, as kind of a ‘Hail Mary’ move, I went back to WallE3_WallTrack_V2, which I vaguely remember as the source of the successful ‘two break’ run, and tried it without modification. Lo and Behold – IT WORKED! Whew, I was beginning to wonder if maybe (despite having a video) it was all a dream!

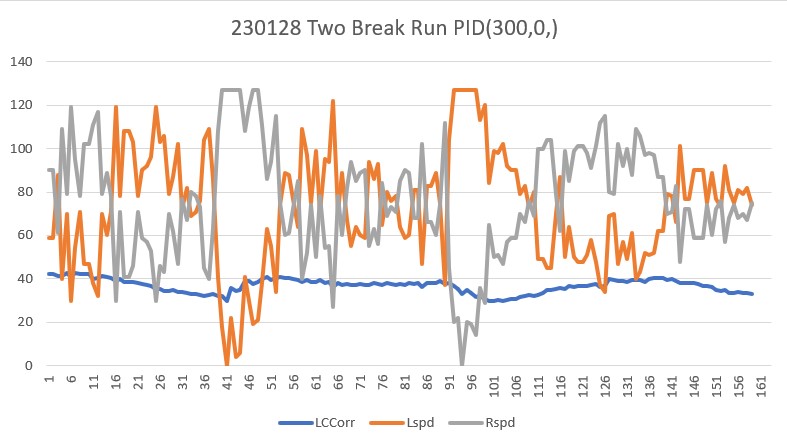

So, now I have a baseline – yes!!! Here’s the output and video from a successful ‘two break’ run:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 |

TrackLeftWallOffset: Start tracking offset of 40.00cm with Kp/Ki/Kd = 300.00 0.00 0.00 Msec Fdir Cdir Rdir Steer Set error Ival Kp*err Ki*Ival Kd*Din Output Lspd Rspd 15682 405 436 405 0.04 0.00 -0.04 0.00 -10.80 0.00 -0.00 -10.80 64 85 15732 406 440 401 0.09 0.00 -0.09 0.00 -27.00 0.00 -0.00 -27.00 48 102 15782 414 437 402 0.16 0.00 -0.16 0.00 -47.10 0.00 -0.00 -47.10 27 122 15832 406 433 402 0.07 0.00 -0.07 0.00 -21.90 0.00 0.00 -21.90 53 96 15882 401 430 399 0.05 0.00 -0.05 0.00 -15.00 0.00 0.00 -15.00 60 90 15932 408 431 404 0.07 0.00 -0.07 0.00 -21.30 0.00 -0.00 -21.30 53 96 15982 406 420 408 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 75 75 16032 409 435 405 0.08 0.00 -0.08 0.00 -22.50 0.00 -0.00 -22.50 52 97 16082 409 435 405 0.08 0.00 -0.08 0.00 -22.50 0.00 0.00 -22.50 52 97 16132 413 427 410 0.06 0.00 -0.06 0.00 -17.10 0.00 0.00 -17.10 57 92 16182 403 426 405 0.01 0.00 -0.01 0.00 -1.80 0.00 0.00 -1.80 73 76 16232 391 425 403 -0.09 0.00 0.09 0.00 28.50 0.00 0.00 28.50 103 46 16282 397 420 399 0.00 0.00 0.00 0.00 0.00 0.00 -0.00 0.00 75 75 16332 384 415 393 -0.08 0.00 0.08 0.00 22.50 0.00 0.00 22.50 97 52 16382 381 407 392 -0.10 0.00 0.10 0.00 30.90 0.00 0.00 30.90 105 44 16432 387 401 387 0.00 0.00 -0.00 0.00 -0.30 0.00 -0.00 -0.30 74 75 16482 372 395 371 0.00 0.00 -0.00 0.00 -1.50 0.00 -0.00 -1.50 73 76 16532 372 395 371 0.00 0.00 -0.00 0.00 -1.50 0.00 0.00 -1.50 73 76 16582 364 382 372 -0.10 0.00 0.10 0.00 29.40 0.00 0.00 29.40 104 45 16632 357 387 369 -0.13 0.00 0.13 0.00 39.90 0.00 0.00 39.90 114 35 16682 351 376 362 -0.13 0.00 0.13 0.00 40.20 0.00 0.00 40.20 115 34 16732 349 370 358 -0.12 0.00 0.12 0.00 36.00 0.00 -0.00 36.00 111 39 16782 346 360 348 -0.06 0.00 0.06 0.00 18.00 0.00 -0.00 18.00 93 57 16832 344 355 344 -0.05 0.00 0.05 0.00 13.50 0.00 -0.00 13.50 88 61 16882 331 352 343 -0.17 0.00 0.17 0.00 50.40 0.00 0.00 50.40 125 24 16932 336 345 333 -0.03 0.00 0.03 0.00 7.50 0.00 -0.00 7.50 82 67 16982 326 343 339 -0.19 0.00 0.19 0.00 56.10 0.00 0.00 56.10 131 18 17032 329 337 327 -0.04 0.00 0.04 0.00 12.90 0.00 -0.00 12.90 87 62 17082 324 335 326 -0.08 0.00 0.08 0.00 25.50 0.00 0.00 25.50 100 49 17132 330 343 319 0.05 0.00 -0.05 0.00 -15.90 0.00 -0.00 -15.90 59 90 17182 341 357 319 0.18 0.00 -0.18 0.00 -53.10 0.00 -0.00 -53.10 21 128 17232 355 382 334 0.20 0.00 -0.20 0.00 -60.60 0.00 -0.00 -60.60 14 135 17282 363 394 345 0.17 0.00 -0.17 0.00 -52.20 0.00 0.00 -52.20 22 127 17332 369 394 357 0.11 0.00 -0.11 0.00 -34.20 0.00 0.00 -34.20 40 109 17382 377 398 365 0.12 0.00 -0.12 0.00 -35.40 0.00 -0.00 -35.40 39 110 17432 392 403 369 0.23 0.00 -0.23 0.00 -69.90 0.00 -0.00 -69.90 5 144 17482 384 407 367 0.18 0.00 -0.18 0.00 -53.10 0.00 0.00 -53.10 21 128 17532 389 406 375 0.15 0.00 -0.15 0.00 -43.80 0.00 0.00 -43.80 31 118 17582 382 407 375 0.08 0.00 -0.08 0.00 -23.10 0.00 0.00 -23.10 51 98 17632 383 409 383 0.01 0.00 -0.01 0.00 -2.70 0.00 0.00 -2.70 72 77 17682 381 404 384 -0.03 0.00 0.03 0.00 7.80 0.00 0.00 7.80 82 67 17732 382 408 382 0.01 0.00 -0.01 0.00 -2.40 0.00 -0.00 -2.40 72 77 17782 397 419 382 0.17 0.00 -0.17 0.00 -50.70 0.00 -0.00 -50.70 24 125 17832 393 404 380 0.13 0.00 -0.13 0.00 -40.20 0.00 0.00 -40.20 34 115 17882 389 406 387 0.03 0.00 -0.03 0.00 -7.80 0.00 0.00 -7.80 67 82 17932 396 417 390 0.08 0.00 -0.08 0.00 -23.10 0.00 -0.00 -23.10 51 98 17982 396 407 390 0.07 0.00 -0.07 0.00 -20.10 0.00 0.00 -20.10 54 95 18032 388 418 389 0.01 0.00 -0.01 0.00 -2.40 0.00 0.00 -2.40 72 77 18082 385 404 386 -0.01 0.00 0.01 0.00 1.80 0.00 0.00 1.80 76 73 18132 385 405 388 -0.02 0.00 0.02 0.00 7.50 0.00 0.00 7.50 82 67 18182 388 407 386 0.03 0.00 -0.03 0.00 -8.10 0.00 -0.00 -8.10 66 83 18232 380 399 383 -0.03 0.00 0.03 0.00 9.30 0.00 0.00 9.30 84 65 18282 383 398 383 -0.00 0.00 0.00 0.00 0.60 0.00 -0.00 0.60 75 74 18332 379 399 386 -0.07 0.00 0.07 0.00 21.30 0.00 0.00 21.30 96 53 18382 379 398 383 -0.06 0.00 0.06 0.00 18.60 0.00 -0.00 18.60 93 56 18432 381 400 381 0.00 0.00 0.00 0.00 0.00 0.00 -0.00 0.00 75 75 18482 376 395 377 -0.01 0.00 0.01 0.00 4.50 0.00 0.00 4.50 79 70 18532 377 399 375 0.02 0.00 -0.02 0.00 -5.70 0.00 -0.00 -5.70 69 80 18582 372 400 372 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 75 75 18632 376 399 373 -0.03 0.00 0.03 0.00 9.30 0.00 0.00 9.30 84 65 18682 374 395 376 -0.02 0.00 0.02 0.00 7.50 0.00 -0.00 7.50 82 67 18732 374 395 376 -0.02 0.00 0.02 0.00 7.50 0.00 0.00 7.50 82 67 18782 377 402 380 -0.03 0.00 0.03 0.00 8.40 0.00 0.00 8.40 83 66 18832 378 398 370 0.08 0.00 -0.08 0.00 -23.40 0.00 -0.00 -23.40 51 98 18882 377 393 377 -0.01 0.00 0.01 0.00 2.10 0.00 0.00 2.10 77 72 18932 377 393 377 -0.01 0.00 0.01 0.00 2.10 0.00 0.00 2.10 77 72 18982 381 403 371 0.10 0.00 -0.10 0.00 -30.90 0.00 -0.00 -30.90 44 105 19032 384 403 371 0.10 0.00 -0.10 0.00 -30.90 0.00 0.00 -30.90 44 105 19082 384 395 383 0.00 0.00 -0.00 0.00 -1.50 0.00 0.00 -1.50 73 76 19132 381 409 377 0.05 0.00 -0.05 0.00 -14.70 0.00 -0.00 -14.70 60 89 19182 381 395 381 -0.00 0.00 0.00 0.00 1.50 0.00 0.00 1.50 76 73 19232 384 399 377 0.07 0.00 -0.07 0.00 -20.70 0.00 -0.00 -20.70 54 95 19282 377 404 380 -0.03 0.00 0.03 0.00 7.80 0.00 0.00 7.80 82 67 19332 385 404 380 -0.03 0.00 0.03 0.00 7.80 0.00 0.00 7.80 82 67 19382 377 408 379 -0.01 0.00 0.01 0.00 3.60 0.00 -0.00 3.60 78 71 19432 381 405 380 0.01 0.00 -0.01 0.00 -4.50 0.00 -0.00 -4.50 70 79 19482 384 405 380 0.04 0.00 -0.04 0.00 -13.50 0.00 -0.00 -13.50 61 88 19532 381 407 385 -0.03 0.00 0.03 0.00 9.90 0.00 0.00 9.90 84 65 19582 384 404 381 0.03 0.00 -0.03 0.00 -10.20 0.00 -0.00 -10.20 64 85 19632 384 401 379 0.05 0.00 -0.05 0.00 -15.30 0.00 -0.00 -15.30 59 90 19682 383 404 382 0.01 0.00 -0.01 0.00 -4.20 0.00 0.00 -4.20 70 79 19732 388 410 383 0.06 0.00 -0.06 0.00 -18.00 0.00 -0.00 -18.00 57 93 19782 379 405 383 -0.04 0.00 0.04 0.00 10.50 0.00 0.00 10.50 85 64 19832 370 400 383 -0.13 0.00 0.13 0.00 39.00 0.00 0.00 39.00 114 36 19882 356 374 380 -0.27 0.00 0.27 0.00 79.80 0.00 0.00 79.80 154 0 19932 348 378 364 -0.18 0.00 0.18 0.00 54.60 0.00 -0.00 54.60 129 20 19982 331 357 353 -0.26 0.00 0.26 0.00 78.90 0.00 0.00 78.90 153 0 20032 329 340 353 -0.30 0.00 0.30 0.00 90.00 0.00 0.00 90.00 165 0 20082 324 337 345 -0.27 0.00 0.27 0.00 81.90 0.00 -0.00 81.90 156 0 20132 305 324 326 -0.29 0.00 0.29 0.00 85.80 0.00 0.00 85.80 160 0 20182 297 318 317 -0.28 0.00 0.28 0.00 84.60 0.00 -0.00 84.60 159 0 20232 299 313 302 -0.12 0.00 0.12 0.00 35.10 0.00 -0.00 35.10 110 39 20282 297 301 297 -0.10 0.00 0.10 0.00 29.70 0.00 -0.00 29.70 104 45 20332 298 303 292 -0.04 0.00 0.04 0.00 11.10 0.00 -0.00 11.10 86 63 20382 305 305 292 0.03 0.00 -0.03 0.00 -10.50 0.00 -0.00 -10.50 64 85 20432 318 322 304 0.06 0.00 -0.06 0.00 -18.60 0.00 -0.00 -18.60 56 93 20482 331 326 310 0.14 0.00 -0.14 0.00 -40.80 0.00 -0.00 -40.80 34 115 20532 331 326 310 0.14 0.00 -0.14 0.00 -40.80 0.00 0.00 -40.80 34 115 20582 335 335 319 0.09 0.00 -0.09 0.00 -28.50 0.00 0.00 -28.50 46 103 20632 339 348 321 0.13 0.00 -0.13 0.00 -38.40 0.00 -0.00 -38.40 36 113 20682 344 357 330 0.10 0.00 -0.10 0.00 -29.10 0.00 0.00 -29.10 45 104 20732 347 365 342 0.02 0.00 -0.02 0.00 -4.50 0.00 0.00 -4.50 70 79 20782 356 369 339 0.14 0.00 -0.14 0.00 -41.70 0.00 -0.00 -41.70 33 116 20832 358 370 348 0.07 0.00 -0.07 0.00 -21.00 0.00 0.00 -21.00 54 96 20882 354 378 352 -0.00 0.00 0.00 0.00 0.60 0.00 0.00 0.60 75 74 20932 359 378 352 -0.00 0.00 0.00 0.00 0.60 0.00 0.00 0.60 75 74 20982 359 385 354 0.04 0.00 -0.04 0.00 -10.50 0.00 -0.00 -10.50 64 85 21032 361 380 352 0.07 0.00 -0.07 0.00 -21.00 0.00 -0.00 -21.00 54 96 21082 361 387 360 -0.00 0.00 0.00 0.00 0.90 0.00 0.00 0.90 75 74 21132 371 384 360 0.09 0.00 -0.09 0.00 -28.20 0.00 -0.00 -28.20 46 103 21182 375 399 369 0.06 0.00 -0.06 0.00 -17.70 0.00 0.00 -17.70 57 92 21232 381 404 381 0.00 0.00 -0.00 0.00 -1.20 0.00 0.00 -1.20 73 76 21282 379 403 373 0.06 0.00 -0.06 0.00 -18.90 0.00 -0.00 -18.90 56 93 21332 390 403 371 0.19 0.00 -0.19 0.00 -57.90 0.00 -0.00 -57.90 17 132 21382 394 400 379 0.15 0.00 -0.15 0.00 -45.00 0.00 0.00 -45.00 30 120 21432 394 405 385 0.10 0.00 -0.10 0.00 -28.50 0.00 0.00 -28.50 46 103 21482 391 417 386 0.07 0.00 -0.07 0.00 -20.10 0.00 0.00 -20.10 54 95 21532 390 420 389 0.03 0.00 -0.03 0.00 -9.00 0.00 0.00 -9.00 66 84 21582 397 415 387 0.12 0.00 -0.12 0.00 -34.50 0.00 -0.00 -34.50 40 109 21632 397 414 396 0.02 0.00 -0.02 0.00 -7.20 0.00 0.00 -7.20 67 82 21682 396 416 388 0.10 0.00 -0.10 0.00 -28.80 0.00 -0.00 -28.80 46 103 21732 403 422 397 0.08 0.00 -0.08 0.00 -24.60 0.00 0.00 -24.60 50 99 21782 407 423 401 0.08 0.00 -0.08 0.00 -24.90 0.00 -0.00 -24.90 50 99 21832 402 427 402 0.03 0.00 -0.03 0.00 -8.10 0.00 0.00 -8.10 66 83 21882 397 434 392 0.08 0.00 -0.08 0.00 -25.20 0.00 -0.00 -25.20 49 100 21932 409 429 399 0.13 0.00 -0.13 0.00 -38.70 0.00 -0.00 -38.70 36 113 21982 408 430 414 -0.03 0.00 0.03 0.00 9.00 0.00 0.00 9.00 84 66 22032 403 428 400 0.06 0.00 -0.06 0.00 -17.40 0.00 -0.00 -17.40 57 92 22082 403 428 400 0.06 0.00 -0.06 0.00 -17.40 0.00 0.00 -17.40 57 92 22132 401 424 403 0.00 0.00 -0.00 0.00 -1.20 0.00 0.00 -1.20 73 76 22182 402 421 406 -0.02 0.00 0.02 0.00 5.70 0.00 0.00 5.70 80 69 22232 400 421 402 0.00 0.00 -0.00 0.00 -0.30 0.00 -0.00 -0.30 74 75 |

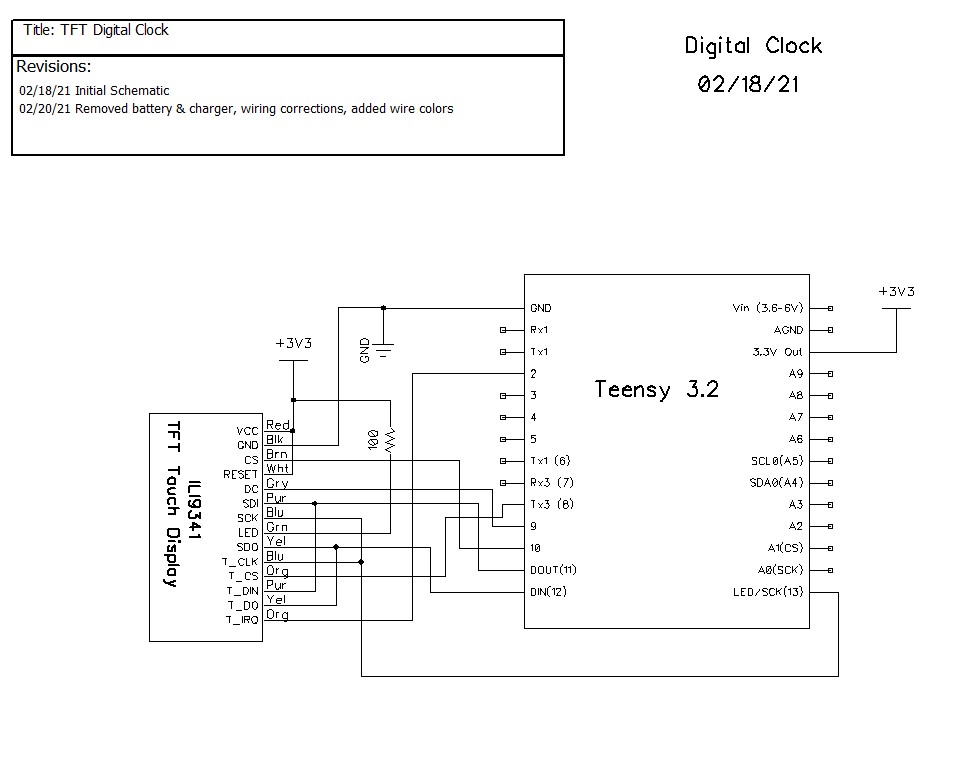

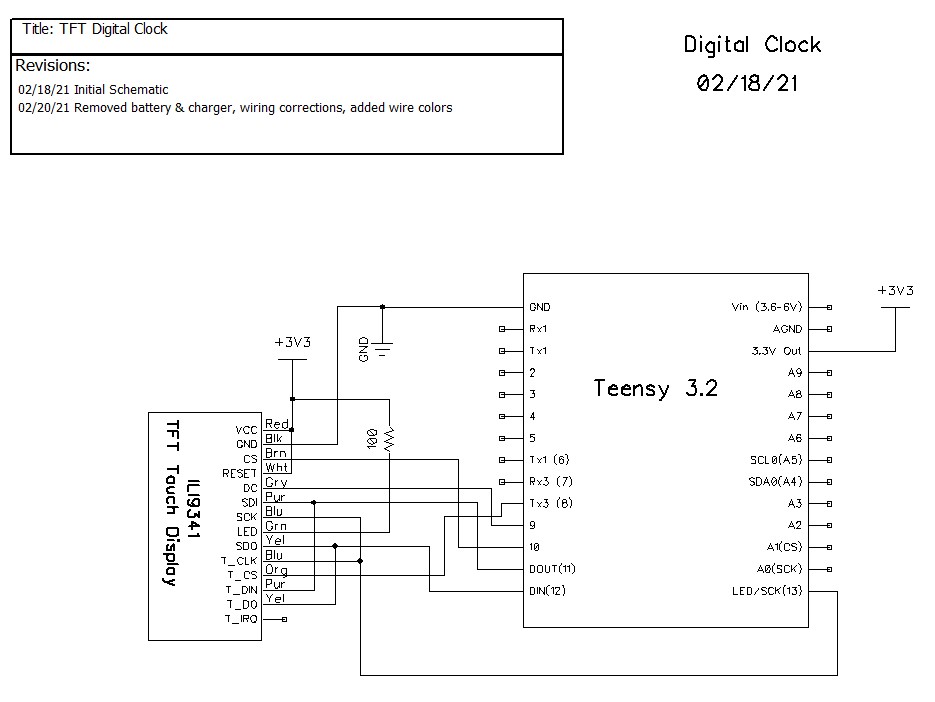

And here is the wall tracking code for this run:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 |

void TrackLeftWallOffset(float kp, float ki, float kd, float offsetCm) { //Notes: // 06/21/21 modified to do a turn, then straight, then track 0 steer val mSecSinceLastWallTrackUpdate = 0; float lastError = 0; float lastInput = 0; float lastIval = 0; float lastDerror = 0; float spinRateDPS = 30; GetRequestedVL53l0xValues(VL53L0X_LEFT); //update glLeftSteeringVal myTeePrint.printf("\nIn TrackLeftWallOffset with Kp/Ki/Kd = %2.2f\t%2.2f\t%2.2f\n", kp, ki, kd); //06/21/21 modified to do a turn, then straight, then track 0 steer val float cutAngleDeg = WALL_OFFSET_TGTDIST_CM - (int)(glLidar_LeftCenter / 10.f);//positive inside, negative outside desired offset myTeePrint.printf("R/C/F dists = %d\t%d\t%d Steerval = %2.3f, CutAngle = %2.2f\n", glLidar_LeftRear, glLidar_LeftCenter, glLidar_LeftFront, glLeftSteeringVal, cutAngleDeg); //07/05/21 implement min cut angle if (cutAngleDeg < 0 && abs(cutAngleDeg) < WALL_OFFSET_APPR_ANGLE_MINDEG) { myTeePrint.printf("(cutAngleDeg < 0 && abs(cutAngleDeg) < %d -- setting to -%d\n", WALL_OFFSET_APPR_ANGLE_MINDEG, WALL_OFFSET_APPR_ANGLE_MINDEG); cutAngleDeg = -WALL_OFFSET_APPR_ANGLE_MINDEG; } else if (cutAngleDeg > 0 && cutAngleDeg < WALL_OFFSET_APPR_ANGLE_MINDEG) { myTeePrint.printf("(cutAngleDeg > 0 && abs(cutAngleDeg) < %d -- setting to +%d\n", WALL_OFFSET_APPR_ANGLE_MINDEG, WALL_OFFSET_APPR_ANGLE_MINDEG); cutAngleDeg = WALL_OFFSET_APPR_ANGLE_MINDEG; } //get the steering angle from the steering value, for comparison to the computed cut angle //positive value means robot is oriented away from wall float SteerAngleDeg = GetSteeringAngle(glLeftSteeringVal); GetRequestedVL53l0xValues(VL53L0X_LEFT); myTeePrint.printf("R/C/F dists = %d\t%d\t%d Steerval = %2.3f, SteerAngle = %2.2f, CutAngle = %2.2f\n", glLidar_LeftRear, glLidar_LeftCenter, glLidar_LeftFront, glLeftSteeringVal, SteerAngleDeg, cutAngleDeg); //now decide which way to turn. int16_t fudgeFactorMM = 0; //07/05/21 added so can change for inside vs outside starting condx if (cutAngleDeg > 0) //robot inside desired offset distance { if (SteerAngleDeg > cutAngleDeg) // --> SteerAngleDeg also > 0, have to turn CCW { myTeePrint.printf("CutAngDeg > 0, SteerAngleDeg > cutAngleDeg - Turn CCW to cut angle\n"); SpinTurn(true, SteerAngleDeg - cutAngleDeg, spinRateDPS); // } else //(SteerAngleDeg <= cutAngleDeg)// --> SteerAngleDeg could be < 0 { myTeePrint.printf("CutAngDeg > 0, SteerAngleDeg < cutAngleDeg\n"); SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //turn diff between SteerAngleDeg & cutAngleDeg } fudgeFactorMM = -100; //07/05/21 don't need fudge factor for inside start condx } else // cutAngleDeg < 0 --> robot outside desired offset distance { if (SteerAngleDeg > cutAngleDeg) // --> SteerAngleDeg may also be > 0 { //robot turned too far toward wall myTeePrint.printf("CutAngDeg < 0, SteerAngleDeg > cutAngleDeg\n"); SpinTurn(true, SteerAngleDeg - cutAngleDeg, spinRateDPS); // } else// (SteerAngleDeg < cutAngleDeg)// --> SteerAngleDeg must also be < 0 { //robot turned to far away from wall myTeePrint.printf("CutAngDeg < 0, SteerAngleDeg <= 0\n"); SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //null out SteerAngleDeg & then turn addnl cutAngleDeg } fudgeFactorMM = 100; //07/05/21 need fudge factor for outside start condx } myTeePrint.printf("fudgeFactorMM = %d\n", fudgeFactorMM); delay(1000); //adjust so offset capture occurs at correct perpendicular offset float adjfactor = cos(PI * cutAngleDeg / 180.f); float numerator = 10 * (float)WALL_OFFSET_TGTDIST_CM; float adjOffsetMM = (numerator / adjfactor); adjOffsetMM += fudgeFactorMM; //fudge factor for distance measurements lagging behind robot's travel. myTeePrint.printf("\nat approach start: cut angle = %2.3f, adjfactor = %2.3f, num = %2.2f, tgt dist = %2.2f\n", cutAngleDeg, adjfactor, numerator, adjOffsetMM); GetRequestedVL53l0xValues(VL53L0X_ALL); //added 09/05/21 long int err = glLidar_LeftFront - adjOffsetMM; //neg for inside going out, pos for outside going in long int prev_err = err; myTeePrint.printf("At start - err = prev_err = %ld\n", err, prev_err); SteerAngleDeg = GetSteeringAngle(glLeftSteeringVal); myTeePrint.printf("R/C/F dists = %d\t%d\t%d Steerval = %2.3f, SteerAngle = %2.2f, CutAngle = %2.2f, err/prev_err = %li\n", glLidar_LeftRear, glLidar_LeftCenter, glLidar_LeftFront, glLeftSteeringVal, SteerAngleDeg, cutAngleDeg, err); myTeePrint.printf("Msec\tLFront\tLCtr\tLRear\tFront\tRear\tErr\tP_err\n"); //TIMSK5 = 0; //turn off TIMER5 interrupts //09/05/21 rev to doublecheck robot position - might not need the forward motion section while (((cutAngleDeg > 0 && err < 0) || (cutAngleDeg <= 0 && err >= 0)) && prev_err * err > 0) //sign change makes this < 0 { prev_err = err; //MoveAhead(MOTOR_SPEED_QTR, MOTOR_SPEED_QTR); MoveAhead(MOTOR_SPEED_FULL, MOTOR_SPEED_FULL); delay(100); glFrontdistval = GetFrontDistCm(); GetRequestedVL53l0xValues(VL53L0X_ALL); err = glLidar_LeftFront - adjOffsetMM; //06/29/21 now adj for slant dist vs perp dist myTeePrint.printf("%lu\t%d\t%d\t%d\t%d\t%d\t%ld\t%ld\n", millis(), glLidar_LeftFront, glLidar_LeftCenter, glLidar_LeftRear, glFrontdistval, glLidar_Rear, err, prev_err); CheckForUserInput(); } //now turn back the same (unadjusted) amount myTeePrint.printf("At end of offset capture - prev_res*res = %ld\n", prev_err * err); myTeePrint.printf("correct back to parallel\n"); SpinTurn(!(cutAngleDeg < 0), abs(cutAngleDeg), spinRateDPS); //have to use abs() here, as cutAngleDeg can be neg WallTrackSetPoint = 0; //moved here 6/22/21 //TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt myTeePrint.printf("\nTrackLeftWallOffset: Start tracking offset of %2.2fcm with Kp/Ki/Kd = %2.2f\t%2.2f\t%2.2f\n", offsetCm, kp, ki, kd); myTeePrint.printf("Msec\tFdir\tCdir\tRdir\tSteer\tSet\terror\tIval\tKp*err\tKi*Ival\tKd*Din\tOutput\tLspd\tRspd\n"); mSecSinceLastWallTrackUpdate = 0; //added 09/04/21 while (true) { CheckForUserInput(); //this is a bit recursive, but should still work (I hope) //now using TIMER5 100 mSec interrupt for timing //if (bTimeForNavUpdate) //{ // //mSecSinceLastWallTrackUpdate -= WALL_TRACK_UPDATE_INTERVAL_MSEC; // bTimeForNavUpdate = false; //09/04/21 back to elapsedMillis timing if (mSecSinceLastWallTrackUpdate > WALL_TRACK_UPDATE_INTERVAL_MSEC) { mSecSinceLastWallTrackUpdate -= WALL_TRACK_UPDATE_INTERVAL_MSEC; GetRequestedVL53l0xValues(VL53L0X_LEFT); //now done in TIMER5 ISR //have to weight value by both angle and wall offset WallTrackSteerVal = glLeftSteeringVal + (glLidar_LeftCenter - 10 * WALL_OFFSET_TGTDIST_CM) / 1000.f; //update motor speeds, skipping bad values if (!isnan(WallTrackSteerVal)) { //02/05/22 sampleTime removed from signature WallTrackOutput = PIDCalcs(WallTrackSteerVal, WallTrackSetPoint, lastError, lastInput, lastIval, lastDerror, kp, ki, kd); int glLeftspeednum = MOTOR_SPEED_QTR + WallTrackOutput; int glRightspeednum = MOTOR_SPEED_QTR - WallTrackOutput; glRightspeednum = (glRightspeednum <= MOTOR_SPEED_FULL) ? glRightspeednum : MOTOR_SPEED_FULL; glRightspeednum = (glRightspeednum > 0) ? glRightspeednum : 0; glLeftspeednum = (glLeftspeednum <= MOTOR_SPEED_FULL) ? glLeftspeednum : MOTOR_SPEED_FULL; glLeftspeednum = (glLeftspeednum > 0) ? glLeftspeednum : 0; MoveAhead(glLeftspeednum, glRightspeednum); myTeePrint.printf("%lu \t%d\t%d\t%d \t%2.2f\t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%d\t%d\n", millis(), glLidar_LeftFront, glLidar_LeftCenter, glLidar_LeftRear, WallTrackSteerVal, WallTrackSetPoint, lastError, lastIval, kp * lastError, ki * lastIval, kd * lastDerror, WallTrackOutput, glLeftspeednum, glRightspeednum); } } } } |

And here is just the wall tracking portion of the above function:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 |

WallTrackSetPoint = 0; //moved here 6/22/21 //TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt myTeePrint.printf("\nTrackLeftWallOffset: Start tracking offset of %2.2fcm with Kp/Ki/Kd = %2.2f\t%2.2f\t%2.2f\n", offsetCm, kp, ki, kd); myTeePrint.printf("Msec\tFdir\tCdir\tRdir\tSteer\tSet\terror\tIval\tKp*err\tKi*Ival\tKd*Din\tOutput\tLspd\tRspd\n"); mSecSinceLastWallTrackUpdate = 0; //added 09/04/21 while (true) { CheckForUserInput(); //this is a bit recursive, but should still work (I hope) //now using TIMER5 100 mSec interrupt for timing //if (bTimeForNavUpdate) //{ // //mSecSinceLastWallTrackUpdate -= WALL_TRACK_UPDATE_INTERVAL_MSEC; // bTimeForNavUpdate = false; //09/04/21 back to elapsedMillis timing if (mSecSinceLastWallTrackUpdate > WALL_TRACK_UPDATE_INTERVAL_MSEC) { mSecSinceLastWallTrackUpdate -= WALL_TRACK_UPDATE_INTERVAL_MSEC; GetRequestedVL53l0xValues(VL53L0X_LEFT); //now done in TIMER5 ISR //have to weight value by both angle and wall offset WallTrackSteerVal = glLeftSteeringVal + (glLidar_LeftCenter - 10 * WALL_OFFSET_TGTDIST_CM) / 1000.f; //update motor speeds, skipping bad values if (!isnan(WallTrackSteerVal)) { //02/05/22 sampleTime removed from signature WallTrackOutput = PIDCalcs(WallTrackSteerVal, WallTrackSetPoint, lastError, lastInput, lastIval, lastDerror, kp, ki, kd); int glLeftspeednum = MOTOR_SPEED_QTR + WallTrackOutput; int glRightspeednum = MOTOR_SPEED_QTR - WallTrackOutput; glRightspeednum = (glRightspeednum <= MOTOR_SPEED_FULL) ? glRightspeednum : MOTOR_SPEED_FULL; glRightspeednum = (glRightspeednum > 0) ? glRightspeednum : 0; glLeftspeednum = (glLeftspeednum <= MOTOR_SPEED_FULL) ? glLeftspeednum : MOTOR_SPEED_FULL; glLeftspeednum = (glLeftspeednum > 0) ? glLeftspeednum : 0; MoveAhead(glLeftspeednum, glRightspeednum); myTeePrint.printf("%lu \t%d\t%d\t%d \t%2.2f\t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%d\t%d\n", millis(), glLidar_LeftFront, glLidar_LeftCenter, glLidar_LeftRear, WallTrackSteerVal, WallTrackSetPoint, lastError, lastIval, kp * lastError, ki * lastIval, kd * lastDerror, WallTrackOutput, glLeftspeednum, glRightspeednum); } } } |

From the above, it appears that WallE3_WallTrack_V2 uses a ‘steering value’ setpoint of zero, and also ‘tweaks’ the input to the PID engine using the error between the measured wall distance and the desired wall offset, as shown in the following snippet:

|

1 2 3 4 5 6 7 8 9 10 |

//have to weight value by both angle and wall offset WallTrackSteerVal = glLeftSteeringVal + (glLidar_LeftCenter - 10 * WALL_OFFSET_TGTDIST_CM) / 1000.f; //update motor speeds, skipping bad values if (!isnan(WallTrackSteerVal)) { //02/05/22 sampleTime removed from signature WallTrackOutput = PIDCalcs(WallTrackSteerVal, WallTrackSetPoint, lastError, lastInput, lastIval, lastDerror, kp, ki, kd); |

This is very similar to what I was trying to do in WallE3_WallTrackTuning_V5 initially below (copied here from ’24 January 2023 Update:’ above for convenience):

|

1 2 3 4 |

//from Teensy_7VL53L0X_I2C_Slave_V3.ino: LeftSteeringVal = (LF_Dist_mm - LR_Dist_mm) / 100.f; //rev 06/21/20 see PPalace post glLeftCentCorrCm = CorrDistForOrient(glLeftCenterCm, glLeftSteeringVal); float offset_factor = (glLeftCentCorrCm - OffCm) / 10.f; WallTrackSteerVal = glLeftSteeringVal + offset_factor; |

So, the original Tuning_V5 math appears to be identical to the WallTrack_V2 math; both use an offset factor as shown:

WallE3_WallTrackTuning_V5:

|

1 2 |

float offset_factor = (glLeftCentCorrCm - OffCm) / 10.f; WallTrackSteerVal = glLeftSteeringVal + offset_factor; |

WallE3_WallTrack_V2:

|

1 |

WallTrackSteerVal = glLeftSteeringVal + (glLidar_LeftCenter - 10 * WALL_OFFSET_TGTDIST_CM) / 1000.f; |

Aha! In WallE3_WallTrack_V2 the offset error (in mm) is divided by 1000, but in WallE3_WallTrackTuning_V5 the offset error (in cm) is divided by 10, which still leaves a factor of 10 difference between the two algorithms! I should be dividing the cm offset by 100 – not 10!

28 January 2023 Update:

SUCCESS!!! So I went back to my WallE3_WallTrackTuning_V5 program, and modified it to be the same as WallE3_WallTrack_V2, except using distances in cm instead of mm, and dividing by 100 instead of 10. After the usual number of stupid errors, I got the following successful run on the ‘two break’ wall setup:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 |

WallE3_WallTrackTuning_V5.ino: TrackLeftWallOffset: Start tracking offset of 40.0 cm with Kp/Ki/Kd = 300.00 0.00 0.00 Msec LF LC LR Steer Deg Cos LCCorr Set Err SpinDeg WallE3_WallTrackTuning_V5.ino: In TrackLeftWallOffset: before while with errcode = NO_ANOMALIES Msec LF LC LR LCCorr OffCm tErr LastI LastD Out Lspd Rspd 44127 39.60 42.20 39.30 42.14 40.00 -0.05 0.00 -0.05 -15.41 59 90 44177 39.60 42.20 39.30 42.14 40.00 -0.05 0.00 0.00 -15.41 59 90 44227 39.30 41.70 39.90 41.46 40.00 0.05 0.00 0.10 13.63 88 61 44277 40.50 42.10 39.50 41.42 40.00 -0.11 0.00 -0.16 -34.26 40 109 44327 39.50 42.60 39.60 42.59 40.00 -0.02 0.00 0.10 -4.78 70 79 44377 40.30 42.20 38.90 40.88 40.00 -0.15 0.00 -0.13 -44.64 30 119 44427 40.10 42.80 39.70 42.69 40.00 -0.07 0.00 0.08 -20.07 54 95 44477 39.50 42.30 39.60 42.29 40.00 -0.01 0.00 0.05 -3.88 71 78 44527 39.90 42.60 39.20 42.26 40.00 -0.09 0.00 -0.08 -27.78 47 102 44577 40.10 42.60 39.20 42.26 40.00 -0.09 0.00 0.00 -27.78 47 102 44627 40.10 41.10 38.90 40.15 40.00 -0.12 0.00 -0.03 -36.45 38 111 44677 40.30 41.50 38.90 40.20 40.00 -0.14 0.00 -0.02 -42.61 32 117 44727 39.20 41.40 39.20 41.40 40.00 -0.01 0.00 0.13 -4.20 70 79 44777 38.70 40.90 38.30 40.79 40.00 -0.05 0.00 -0.03 -14.38 60 89 44827 38.40 40.30 38.30 40.29 40.00 -0.01 0.00 0.03 -3.88 71 78 44877 37.90 40.30 39.30 39.04 40.00 0.15 0.00 0.16 44.88 119 30 44927 37.90 40.00 38.00 39.99 40.00 0.01 0.00 -0.14 3.02 78 71 44977 37.30 39.40 38.30 38.76 40.00 0.11 0.00 0.10 33.71 108 41 45027 37.30 39.40 38.30 38.76 40.00 0.11 0.00 0.00 33.71 108 41 45077 35.90 38.90 36.70 38.50 40.00 0.10 0.00 -0.02 28.51 103 46 45127 36.60 38.00 36.50 37.99 40.00 0.01 0.00 -0.08 3.02 78 71 45177 35.60 37.90 35.90 37.84 40.00 0.05 0.00 0.04 15.47 90 59 45227 35.30 37.30 35.60 37.25 40.00 0.06 0.00 0.01 17.26 92 57 45277 34.70 36.80 35.10 36.70 40.00 0.07 0.00 0.02 21.89 96 53 45327 34.20 35.80 35.20 35.22 40.00 0.15 0.00 0.07 44.33 119 30 45377 34.00 35.60 34.50 35.46 40.00 0.10 0.00 -0.05 28.63 103 46 45427 33.60 34.50 34.50 34.36 40.00 0.11 0.00 0.01 31.92 106 43 45477 33.60 34.50 33.20 34.41 40.00 0.02 0.00 -0.09 4.77 79 70 45527 33.80 34.90 33.70 34.89 40.00 0.04 0.00 0.03 12.32 87 62 45577 32.90 34.00 33.20 33.95 40.00 0.09 0.00 0.05 27.15 102 47 45627 33.20 34.20 32.50 33.93 40.00 -0.01 0.00 -0.10 -2.78 72 77 45677 32.80 33.70 32.40 33.61 40.00 0.02 0.00 0.03 7.16 82 67 45727 33.00 33.40 32.10 32.96 40.00 -0.02 0.00 -0.04 -5.89 69 80 45777 32.60 33.40 31.80 33.05 40.00 -0.01 0.00 0.01 -3.16 71 78 45827 32.60 32.90 31.90 32.64 40.00 0.00 0.00 0.01 1.09 76 73 45877 31.90 32.20 32.10 32.18 40.00 0.10 0.00 0.09 29.46 104 45 45927 31.70 32.60 32.10 32.51 40.00 0.11 0.00 0.02 34.46 109 40 45977 32.40 33.20 32.10 33.15 40.00 0.04 0.00 -0.08 11.55 86 63 46027 33.30 34.10 31.40 32.18 40.00 -0.11 0.00 -0.15 -33.53 41 108 46077 34.80 35.80 32.10 31.89 40.00 -0.19 0.00 -0.08 -56.67 18 127 46127 36.70 37.50 32.90 29.99 40.00 -0.28 0.00 -0.09 -83.96 0 127 46177 37.00 38.50 34.80 35.63 40.00 -0.18 0.00 0.10 -52.89 22 127 46227 37.80 39.40 34.90 34.50 40.00 -0.23 0.00 -0.06 -70.49 4 127 46277 38.60 39.60 35.80 34.98 40.00 -0.23 0.00 0.01 -68.93 6 127 46327 37.70 40.00 36.50 39.08 40.00 -0.11 0.00 0.12 -33.23 41 108 46377 37.60 40.50 36.00 38.86 40.00 -0.15 0.00 -0.04 -44.58 30 119 46427 38.60 40.40 36.50 37.64 40.00 -0.19 0.00 -0.04 -55.92 19 127 46477 38.90 41.00 37.00 38.69 40.00 -0.18 0.00 0.01 -53.06 21 127 46527 38.90 41.10 37.70 40.15 40.00 -0.12 0.00 0.06 -36.45 38 111 46577 38.40 40.90 38.10 40.84 40.00 -0.04 0.00 0.08 -11.52 63 86 46627 39.00 39.70 38.30 39.38 40.00 -0.06 0.00 -0.03 -19.15 55 94 46677 39.80 41.60 38.50 40.48 40.00 -0.13 0.00 -0.07 -40.43 34 115 46727 39.10 41.10 39.20 41.09 40.00 -0.00 0.00 0.13 -0.28 74 75 46777 38.30 40.40 38.80 40.24 40.00 0.05 0.00 0.05 14.29 89 60 46827 38.40 40.80 38.90 40.63 40.00 0.04 0.00 -0.00 13.10 88 61 46877 38.90 40.10 39.00 40.09 40.00 0.01 0.00 -0.03 2.72 77 72 46927 38.20 39.60 38.30 39.50 40.00 -0.03 0.00 -0.04 -10.49 64 85 46977 37.60 39.20 38.60 38.57 40.00 0.11 0.00 0.15 34.30 109 40 47027 37.10 39.80 37.80 39.48 40.00 0.08 0.00 -0.04 22.55 97 52 47077 37.00 38.80 36.90 38.79 40.00 0.00 0.00 -0.07 0.62 75 74 47127 36.50 39.10 37.20 38.79 40.00 0.08 0.00 0.08 24.63 99 50 47177 37.70 39.30 37.50 39.27 40.00 -0.01 0.00 -0.09 -3.82 71 78 47227 36.60 38.20 37.10 38.04 40.00 0.07 0.00 0.08 20.87 95 54 47277 36.70 38.70 37.00 38.54 40.00 0.06 0.00 -0.00 19.37 94 55 47327 36.40 37.10 37.60 36.24 40.00 0.16 0.00 0.09 47.27 122 27 47377 37.00 38.20 36.70 38.14 40.00 -0.01 0.00 -0.17 -3.43 71 78 47427 36.70 37.30 36.90 37.28 40.00 0.05 0.00 0.06 14.17 89 60 47477 37.00 37.60 36.50 37.45 40.00 -0.02 0.00 -0.07 -7.34 67 82 47527 36.90 37.90 36.00 37.40 40.00 -0.06 0.00 -0.04 -19.21 55 94 47577 36.50 37.60 35.90 37.38 40.00 -0.03 0.00 0.03 -10.14 64 85 47627 36.50 38.10 35.80 37.80 40.00 -0.05 0.00 -0.01 -14.39 60 89 47677 36.60 37.50 35.80 37.11 40.00 -0.05 0.00 -0.00 -15.33 59 90 47727 36.00 37.50 36.40 37.40 40.00 0.07 0.00 0.12 19.79 94 55 47777 36.10 38.30 36.30 38.27 40.00 0.04 0.00 -0.03 11.18 86 63 47827 36.10 37.80 36.50 37.70 40.00 0.06 0.00 0.03 18.90 93 56 47877 36.40 37.40 35.80 37.18 40.00 -0.03 0.00 -0.09 -9.54 65 84 47927 35.90 38.20 35.90 38.20 40.00 0.02 0.00 0.05 5.40 80 69 47977 36.40 37.60 36.20 37.58 40.00 0.00 0.00 -0.01 1.27 76 73 48027 35.90 37.00 35.70 36.98 40.00 0.01 0.00 0.01 3.07 78 71 48077 37.00 37.80 36.40 37.58 40.00 -0.04 0.00 -0.05 -10.74 64 85 48127 36.60 37.40 35.80 37.01 40.00 -0.05 0.00 -0.01 -15.04 59 90 48177 36.50 38.20 35.80 37.90 40.00 -0.05 0.00 0.00 -14.69 60 89 48227 36.30 37.80 36.30 37.80 40.00 0.02 0.00 0.07 6.60 81 68 48277 36.50 37.90 36.50 37.90 40.00 0.02 0.00 -0.00 6.30 81 68 48327 37.20 37.30 35.90 36.29 40.00 -0.09 0.00 -0.11 -27.88 47 102 48377 37.00 38.30 37.10 38.29 40.00 0.03 0.00 0.12 8.12 83 66 48427 36.70 38.10 36.10 38.09 40.00 0.03 0.00 0.00 8.72 83 66 48477 36.20 38.10 36.50 38.04 40.00 0.05 0.00 0.02 14.87 89 60 48527 37.00 39.00 36.90 38.99 40.00 0.00 0.00 -0.05 0.02 75 74 48577 37.50 38.90 36.00 37.51 40.00 -0.13 0.00 -0.13 -37.53 37 112 48627 36.40 38.60 37.20 38.20 40.00 0.10 0.00 0.22 29.40 104 45 48677 35.50 38.10 37.00 36.74 40.00 0.18 0.00 0.08 54.79 127 20 48727 35.70 36.40 37.00 35.42 40.00 0.18 0.00 -0.01 52.75 127 22 48777 34.00 36.30 36.50 32.86 40.00 0.32 0.00 0.15 96.42 127 0 48827 34.30 35.80 35.60 34.83 40.00 0.18 0.00 -0.14 54.50 127 20 48877 33.10 34.20 34.30 33.41 40.00 0.19 0.00 0.00 55.77 127 19 48927 31.70 32.60 32.90 31.85 40.00 0.20 0.00 0.02 60.46 127 14 48977 31.30 32.20 31.80 32.07 40.00 0.13 0.00 -0.07 38.79 113 36 49027 30.50 30.90 31.10 30.72 40.00 0.15 0.00 0.02 45.84 120 29 49077 30.70 30.10 30.00 29.86 40.00 0.03 0.00 -0.12 9.42 84 65 49127 30.20 29.80 30.00 29.78 40.00 0.08 0.00 0.05 24.66 99 50 49177 30.00 30.20 29.80 30.18 40.00 0.08 0.00 -0.00 23.46 98 51 49227 30.10 29.70 30.00 29.70 40.00 0.09 0.00 0.01 27.91 102 47 49277 30.20 30.30 29.80 30.22 40.00 0.06 0.00 -0.04 17.34 92 57 49327 30.60 31.00 29.80 30.92 40.00 0.05 0.00 -0.01 15.24 90 59 49377 30.60 31.00 30.20 30.92 40.00 0.05 0.00 0.00 15.24 90 59 49427 31.50 31.70 30.80 31.45 40.00 0.02 0.00 -0.04 4.66 79 70 49477 31.40 32.30 30.90 32.17 40.00 0.03 0.00 0.01 8.49 83 66 49527 32.30 33.00 31.50 32.66 40.00 -0.01 0.00 -0.03 -1.97 73 76 49577 32.10 32.20 31.50 32.01 40.00 0.02 0.00 0.03 5.97 80 69 49627 33.60 33.90 32.00 32.53 40.00 -0.09 0.00 -0.11 -25.58 49 100 49677 34.00 34.60 32.50 33.36 40.00 -0.08 0.00 0.00 -25.09 49 100 49727 34.30 36.10 32.80 34.81 40.00 -0.10 0.00 -0.01 -29.43 45 104 49777 34.30 36.10 32.80 34.81 40.00 -0.10 0.00 0.00 -29.43 45 104 49827 34.70 35.60 34.10 35.39 40.00 -0.01 0.00 0.08 -4.17 70 79 49877 34.60 35.90 34.60 35.90 40.00 0.04 0.00 0.05 12.30 87 62 49927 35.50 36.30 34.20 35.32 40.00 -0.08 0.00 -0.12 -24.96 50 99 49977 35.90 36.80 35.20 36.51 40.00 -0.04 0.00 0.05 -10.52 64 85 50027 36.40 37.00 35.20 36.15 40.00 -0.08 0.00 -0.05 -24.44 50 99 50077 36.30 37.80 35.10 36.93 40.00 -0.09 0.00 -0.01 -26.78 48 101 50127 36.60 37.80 35.40 36.93 40.00 -0.09 0.00 0.00 -26.78 48 101 50177 37.40 37.60 36.30 36.87 40.00 -0.08 0.00 0.01 -23.60 51 98 50227 37.30 37.80 36.50 37.41 40.00 -0.05 0.00 0.02 -16.22 58 91 50277 37.60 38.50 36.50 37.75 40.00 -0.09 0.00 -0.03 -26.25 48 101 50327 37.40 37.90 35.80 36.36 40.00 -0.12 0.00 -0.04 -37.09 37 112 50377 38.20 38.40 36.50 36.65 40.00 -0.14 0.00 -0.01 -40.95 34 115 50427 37.30 39.90 37.10 39.87 40.00 -0.02 0.00 0.12 -5.62 69 80 50477 37.00 39.60 36.80 39.57 40.00 -0.02 0.00 0.00 -4.72 70 79 50527 38.10 39.70 37.10 39.06 40.00 -0.09 0.00 -0.07 -27.18 47 102 50577 37.60 39.30 36.90 38.99 40.00 -0.06 0.00 0.03 -17.96 57 92 50627 38.60 39.00 37.60 38.37 40.00 -0.08 0.00 -0.02 -25.11 49 100 50677 38.80 39.60 38.30 39.44 40.00 -0.04 0.00 0.04 -13.32 61 88 50727 38.90 40.40 37.70 39.47 40.00 -0.11 0.00 -0.07 -34.40 40 109 50777 39.20 40.30 38.10 39.52 40.00 -0.11 0.00 0.01 -31.55 43 106 50827 38.90 39.10 38.00 38.59 40.00 -0.08 0.00 0.03 -22.76 52 97 50877 39.10 40.30 38.30 39.88 40.00 -0.08 0.00 -0.00 -23.65 51 98 50927 39.00 40.90 38.30 40.57 40.00 -0.08 0.00 0.00 -22.72 52 97 50977 38.70 40.30 38.30 40.19 40.00 -0.04 0.00 0.03 -12.58 62 87 51027 38.70 40.30 38.30 40.19 40.00 -0.04 0.00 0.00 -12.58 62 87 51077 38.30 39.40 38.40 39.39 40.00 0.02 0.00 0.06 4.82 79 70 51127 38.20 39.90 38.30 39.89 40.00 0.01 0.00 -0.00 3.32 78 71 51177 37.60 39.00 37.20 38.90 40.00 -0.03 0.00 -0.04 -8.69 66 83 51227 37.00 38.60 37.70 38.29 40.00 0.09 0.00 0.12 26.12 101 48 51277 37.00 38.30 36.90 38.29 40.00 0.01 0.00 -0.08 2.12 77 72 51327 37.00 38.30 36.90 38.29 40.00 0.01 0.00 0.00 2.12 77 72 51377 37.00 38.00 37.30 37.94 40.00 0.05 0.00 0.04 15.17 90 59 51427 36.20 37.80 36.50 37.74 40.00 0.05 0.00 0.00 15.77 90 59 51477 35.90 36.80 36.10 36.78 40.00 0.05 0.00 -0.00 15.67 90 59 51527 35.90 36.90 35.60 36.85 40.00 0.00 0.00 -0.05 0.46 75 74 51577 35.50 36.20 35.60 36.19 40.00 0.05 0.00 0.05 14.42 89 60 51627 35.50 35.20 35.10 35.11 40.00 0.01 0.00 -0.04 2.68 77 72 51677 34.80 34.70 34.20 34.50 40.00 -0.00 0.00 -0.01 -1.49 73 76 51727 34.60 35.10 34.70 35.09 40.00 0.06 0.00 0.06 17.72 92 57 51777 34.10 33.80 33.70 33.71 40.00 0.02 0.00 -0.04 6.86 81 68 51827 33.90 33.90 33.30 33.70 40.00 0.00 0.00 -0.02 0.90 75 74 51877 34.20 33.90 33.80 33.81 40.00 0.02 0.00 0.02 6.57 81 68 51927 33.60 33.80 33.10 33.66 40.00 0.01 0.00 -0.01 4.01 79 70 51977 33.70 33.70 33.30 33.61 40.00 0.02 0.00 0.01 7.16 82 67 52027 33.30 33.50 32.60 33.23 40.00 -0.00 0.00 -0.03 -0.70 74 75 |

After running this test a couple more times to assure myself that I wasn’t dreaming, I started to play around with the PID values to see if I could get a bit better performance. The first run (shown above) produced an average offset distance of about 36.9cm. A subsequent run showed an average of 26.4cm. This implies that the steering value ‘tweak’ isn’t really doing much. For instance, this line:

|

1 2 |

Msec LF LC LR LCCorr OffCm tErr LastI LastD Out Lspd Rspd 739120 21.40 20.40 19.30 19.01 40.00 -0.00 0.00 -0.08 -0.02 74 75 |

shows that for a corrected distance of 28.13cm, the calculated steerval is (21.4-19.3) /100 = 2.1/100 = 0.021, the ‘offset_factor’ is (40-19.3)/100 = 20.7/100 = 0.207. So, the ‘tweaked’ steerval should be 0.228 and should produce an error term of +0.228 but it is only reporting an error of 0.00!

I added the steerval and the offset_factor to the output telemetry and redid the run with 300,0,0 as before. This time I got

|

1 2 |

Msec LF LC LR LCCorr Steer Tweak OffCm Err LastI LastD Out Lspd Rspd 76092 37.70 39.10 37.10 38.87 0.06 -0.01 40.00 -0.05 0.00 0.05 -14.61 60 89 |

In this case, steerval = (37.7 – 37.1)/100 = +0.06 (pointing slightly away from the wall), tweak = (38.87-40)/100 = -1.13/100 = -0.013, so the total error of +0.0487, giving left/right motor speeds of 60/89, i.e. correcting slightly back toward the wall – oops! It looks like I need to use a slightly smaller divisor for the ‘tweak’ calculation.

|

1 |

float offset_factor = (glLeftCentCorrCm - OffCm) / 100.f; //01/28/23 from https://www.fpaynter.com/2023/01/walle3-wall-track-tuning-review/ |

I added the divisor for the offset_factor to the parameter list for ‘Tuning_V5’ and redid the run, using ‘100’ to make sure I got the same result as before.

I was able to confirm that using this method with the ‘tweak’ divisor as a parameter I got pretty much the same behavior. Then I started reducing the divisor to see what would happen as the ‘tweak’ became more of a factor in the PID calculation.

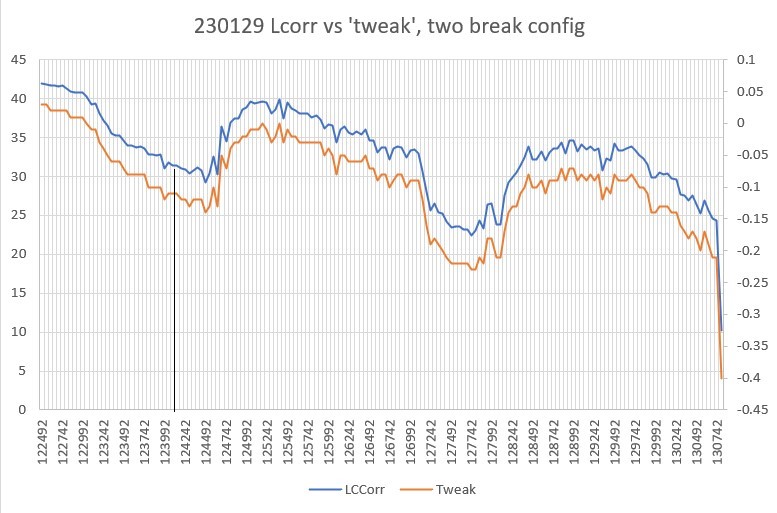

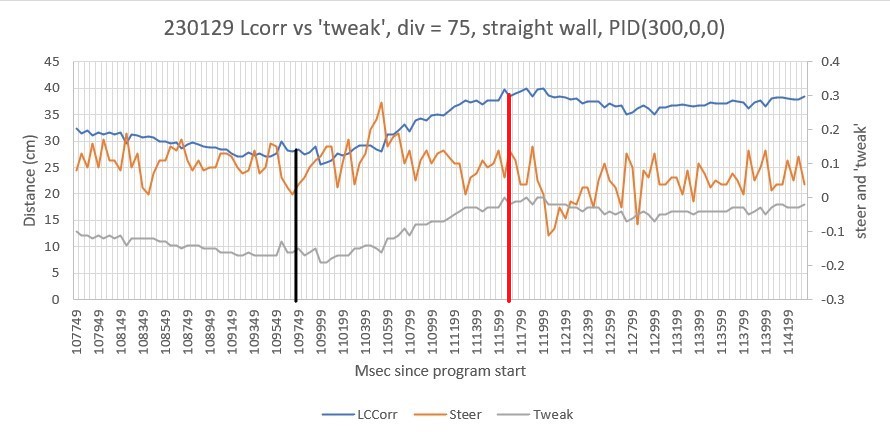

For a divisor of 75, we got the following output:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 |

Msec LF LC LR LCCorr Steer Tweak OffCm Err LastI LastD Out Lspd Rspd 122492 39.20 42.10 38.80 41.99 0.04 0.03 40.00 -0.07 0.00 -0.07 -19.96 55 94 122542 40.20 42.00 38.80 41.89 0.04 0.03 40.00 -0.07 0.00 0.00 -19.56 55 94 122592 40.20 42.00 39.60 41.75 0.06 0.02 40.00 -0.08 0.00 -0.02 -25.02 49 100 122642 40.00 42.20 39.10 41.65 0.09 0.02 40.00 -0.11 0.00 -0.03 -33.59 41 108 122692 39.60 42.70 38.30 41.55 0.13 0.02 40.00 -0.15 0.00 -0.04 -45.18 29 120 122742 39.50 42.00 38.80 41.67 0.07 0.02 40.00 -0.09 0.00 0.06 -27.66 47 102 122792 39.10 41.30 39.30 41.27 -0.02 0.02 40.00 0.00 0.00 0.10 0.91 75 74 122842 39.10 41.10 39.60 40.93 -0.05 0.01 40.00 0.04 0.00 0.03 11.27 86 63 122892 39.80 41.30 38.90 40.76 0.09 0.01 40.00 -0.10 0.00 -0.14 -30.04 44 105 122942 39.20 40.80 39.10 40.79 0.01 0.01 40.00 -0.02 0.00 0.08 -6.17 68 81 122992 39.20 40.80 39.10 40.79 0.01 0.01 40.00 -0.02 0.00 0.00 -6.17 68 81 123042 38.40 40.50 38.90 40.34 -0.05 0.00 40.00 0.05 0.00 0.07 13.66 88 61 123092 37.20 40.50 38.60 39.23 -0.14 -0.01 40.00 0.15 0.00 0.10 45.06 120 29 123142 37.10 39.40 37.30 39.37 -0.02 -0.01 40.00 0.03 0.00 -0.12 8.50 83 66 123192 36.10 38.70 37.10 38.08 -0.10 -0.03 40.00 0.13 0.00 0.10 37.70 112 37 123242 34.40 38.80 36.00 37.23 -0.16 -0.04 40.00 0.20 0.00 0.07 59.09 127 15 123292 34.60 36.80 35.20 36.58 -0.06 -0.05 40.00 0.11 0.00 -0.09 31.66 106 43 123342 34.00 35.60 34.10 35.59 -0.01 -0.06 40.00 0.07 0.00 -0.04 20.62 95 54 123392 33.10 35.30 34.10 35.29 -0.01 -0.06 40.00 0.07 0.00 0.00 21.82 96 53 123442 33.10 35.30 33.40 35.25 -0.03 -0.06 40.00 0.09 0.00 0.02 28.01 103 46 123492 32.70 34.70 32.50 34.68 0.02 -0.07 40.00 0.05 0.00 -0.04 15.29 90 59 123542 32.40 34.50 31.50 34.05 0.09 -0.08 40.00 -0.01 0.00 -0.06 -3.19 71 78 123592 32.10 34.10 31.80 34.05 0.03 -0.08 40.00 0.05 0.00 0.06 14.80 89 60 123642 31.80 33.80 31.90 33.79 -0.01 -0.08 40.00 0.09 0.00 0.04 27.82 102 47 123692 31.50 33.90 31.20 33.85 0.03 -0.08 40.00 0.05 0.00 -0.04 15.60 90 59 123742 31.10 33.90 30.40 33.63 0.07 -0.08 40.00 0.01 0.00 -0.04 4.48 79 70 123792 31.20 33.30 30.30 32.86 0.09 -0.10 40.00 0.01 0.00 -0.01 1.54 76 73 123842 31.20 33.30 30.30 32.86 0.09 -0.10 40.00 0.01 0.00 0.00 1.54 76 73 123892 30.80 33.00 30.10 32.74 0.07 -0.10 40.00 0.03 0.00 0.02 8.05 83 66 123942 30.50 32.80 30.30 32.78 0.02 -0.10 40.00 0.08 0.00 0.05 22.89 97 52 123992 30.70 31.50 29.70 30.99 0.10 -0.12 40.00 0.02 0.00 -0.06 6.03 81 68 124042 30.50 32.30 29.50 31.78 0.10 -0.11 40.00 0.01 0.00 -0.01 2.88 77 72 124092 29.90 31.80 29.10 31.47 0.08 -0.11 40.00 0.03 0.00 0.02 10.12 85 64 124142 29.30 31.50 29.10 31.48 0.02 -0.11 40.00 0.09 0.00 0.06 28.08 103 46 124192 28.90 31.10 29.10 31.08 -0.02 -0.12 40.00 0.14 0.00 0.05 41.68 116 33 124242 29.30 31.20 28.60 30.95 0.07 -0.12 40.00 0.05 0.00 -0.09 15.19 90 59 124292 29.60 31.10 28.40 30.38 0.12 -0.13 40.00 0.01 0.00 -0.04 2.47 77 72 124342 29.70 31.50 28.50 30.77 0.12 -0.12 40.00 0.00 0.00 -0.01 0.91 75 74 124392 30.20 32.30 28.70 31.15 0.15 -0.12 40.00 -0.03 0.00 -0.03 -9.58 65 84 124442 31.50 32.80 29.50 30.76 0.20 -0.12 40.00 -0.08 0.00 -0.04 -23.03 51 98 124492 32.80 33.40 29.90 29.24 0.29 -0.14 40.00 -0.15 0.00 -0.07 -43.97 31 118 124542 34.30 35.70 31.10 30.40 0.32 -0.13 40.00 -0.19 0.00 -0.05 -57.59 17 127 124592 34.70 35.20 32.50 32.57 0.22 -0.10 40.00 -0.12 0.00 0.07 -36.30 38 111 124642 36.00 38.20 32.10 30.20 0.39 -0.13 40.00 -0.26 0.00 -0.14 -77.81 0 127 124692 35.90 38.20 34.20 36.46 0.17 -0.05 40.00 -0.12 0.00 0.14 -36.84 38 111 124742 36.90 38.40 32.90 34.49 0.26 -0.07 40.00 -0.19 0.00 -0.06 -55.95 19 127 124792 36.80 38.70 35.10 36.94 0.17 -0.04 40.00 -0.13 0.00 0.06 -38.75 36 113 124842 37.30 39.30 35.60 37.51 0.17 -0.03 40.00 -0.14 0.00 -0.01 -41.04 33 116 124892 37.50 39.20 35.80 37.41 0.17 -0.03 40.00 -0.14 0.00 0.00 -40.66 34 115 124942 37.10 39.70 35.80 38.63 0.13 -0.02 40.00 -0.11 0.00 0.02 -33.51 41 108 124992 38.00 39.90 36.70 38.82 0.13 -0.02 40.00 -0.11 0.00 -0.00 -34.29 40 109 125042 37.00 40.00 36.20 39.59 0.08 -0.01 40.00 -0.07 0.00 0.04 -22.34 52 97 125092 37.60 39.80 36.80 39.39 0.08 -0.01 40.00 -0.07 0.00 0.00 -21.55 53 96 125142 37.80 40.30 36.70 39.52 0.11 -0.01 40.00 -0.10 0.00 -0.03 -31.06 43 106 125192 37.30 39.80 36.90 39.70 0.04 -0.00 40.00 -0.04 0.00 0.07 -10.78 64 85 125242 36.70 39.60 37.10 39.50 -0.04 -0.01 40.00 0.05 0.00 0.08 14.01 89 60 125292 38.20 39.70 36.60 38.09 0.16 -0.03 40.00 -0.13 0.00 -0.18 -40.37 34 115 125342 37.30 39.80 35.90 38.56 0.14 -0.02 40.00 -0.12 0.00 0.01 -36.23 38 111 125392 37.00 39.90 36.90 39.89 0.01 -0.00 40.00 -0.01 0.00 0.11 -2.57 72 77 125442 37.10 39.10 35.90 37.52 0.16 -0.03 40.00 -0.13 0.00 -0.12 -38.06 36 113 125492 37.10 39.60 36.70 39.50 0.04 -0.01 40.00 -0.03 0.00 0.09 -9.99 65 84 125542 36.40 38.90 36.70 38.80 0.04 -0.02 40.00 -0.02 0.00 0.01 -7.19 67 82 125592 36.70 39.10 35.70 38.47 0.10 -0.02 40.00 -0.08 0.00 -0.06 -23.88 51 98 125642 35.70 38.70 36.70 38.08 -0.10 -0.03 40.00 0.13 0.00 0.21 37.70 112 37 125692 35.50 38.10 35.80 38.04 -0.03 -0.03 40.00 0.06 0.00 -0.07 16.82 91 58 125742 36.20 38.10 35.90 38.04 0.03 -0.03 40.00 -0.00 0.00 -0.06 -1.18 73 76 125792 35.50 37.60 35.50 37.60 0.00 -0.03 40.00 0.03 0.00 0.04 9.60 84 65 125842 34.80 37.80 34.70 37.79 0.01 -0.03 40.00 0.02 0.00 -0.01 5.82 80 69 125892 35.00 37.40 34.90 37.39 0.01 -0.03 40.00 0.02 0.00 0.01 7.42 82 67 125942 35.20 36.40 34.50 36.11 0.07 -0.05 40.00 -0.02 0.00 -0.04 -5.44 69 80 125992 34.30 36.70 34.40 36.69 -0.01 -0.04 40.00 0.05 0.00 0.07 16.22 91 58 126042 34.80 36.60 35.20 36.50 -0.04 -0.05 40.00 0.09 0.00 0.03 25.98 100 49 126092 34.50 35.80 32.90 34.35 0.16 -0.08 40.00 -0.08 0.00 -0.17 -25.40 49 100 126142 34.30 36.10 34.10 36.08 0.02 -0.05 40.00 0.03 0.00 0.12 9.69 84 65 126192 33.30 36.50 33.40 36.49 -0.01 -0.05 40.00 0.06 0.00 0.02 17.02 92 57 126242 33.70 36.40 32.60 35.69 0.11 -0.06 40.00 -0.05 0.00 -0.11 -15.77 59 90 126292 33.40 35.40 33.30 35.35 -0.03 -0.06 40.00 0.09 0.00 0.14 27.61 102 47 126342 33.00 36.00 32.40 35.79 0.06 -0.06 40.00 -0.00 0.00 -0.10 -1.16 73 76 126392 33.00 35.90 32.10 35.43 0.09 -0.06 40.00 -0.03 0.00 -0.03 -8.72 66 83 126442 32.60 36.10 32.30 36.05 0.03 -0.05 40.00 0.02 0.00 0.05 6.81 81 68 126492 32.40 34.70 32.10 34.65 0.03 -0.07 40.00 0.04 0.00 0.02 12.40 87 62 126542 32.50 34.70 32.10 34.61 0.04 -0.07 40.00 0.03 0.00 -0.01 9.56 84 65 126592 32.40 33.70 31.30 33.04 0.11 -0.09 40.00 -0.02 0.00 -0.05 -5.18 69 80 126642 32.10 33.90 31.50 33.70 0.06 -0.08 40.00 0.02 0.00 0.04 7.19 82 67 126692 31.50 33.70 31.50 33.70 0.00 -0.08 40.00 0.08 0.00 0.06 25.20 100 49 126742 32.20 33.40 30.70 32.21 0.15 -0.10 40.00 -0.05 0.00 -0.13 -13.82 61 88 126792 31.90 34.10 30.90 33.55 0.10 -0.09 40.00 -0.01 0.00 0.03 -4.20 70 79 126842 31.70 33.90 31.40 33.85 0.03 -0.08 40.00 0.05 0.00 0.07 15.60 90 59 126892 31.60 33.70 31.50 33.69 0.01 -0.08 40.00 0.07 0.00 0.02 22.22 97 52 126942 32.50 33.60 31.00 32.40 0.15 -0.10 40.00 -0.05 0.00 -0.12 -14.60 60 89 126992 31.80 33.80 30.90 33.36 0.09 -0.09 40.00 -0.00 0.00 0.05 -0.43 74 75 127042 31.30 33.50 31.10 33.48 0.02 -0.09 40.00 0.07 0.00 0.07 20.09 95 54 127092 30.50 33.40 31.40 32.96 -0.09 -0.09 40.00 0.18 0.00 0.12 55.15 127 19 127142 28.80 32.00 30.40 30.70 -0.16 -0.12 40.00 0.28 0.00 0.10 85.19 127 0 127192 27.60 30.30 29.80 28.04 -0.22 -0.16 40.00 0.38 0.00 0.10 113.84 127 0 127242 26.90 27.70 29.10 25.63 -0.22 -0.19 40.00 0.41 0.00 0.03 123.46 127 0 127292 25.00 27.90 27.80 26.48 -0.18 -0.18 40.00 0.36 0.00 -0.05 108.08 127 0 127342 24.40 25.80 26.00 25.38 -0.10 -0.19 40.00 0.29 0.00 -0.07 88.46 127 0 127392 23.80 25.30 24.10 25.26 -0.03 -0.20 40.00 0.23 0.00 -0.07 67.95 127 7 127442 22.80 24.30 23.20 24.24 -0.04 -0.21 40.00 0.25 0.00 0.02 75.05 127 0 127492 22.70 23.40 22.60 23.40 0.01 -0.22 40.00 0.21 0.00 -0.04 63.42 127 11 127542 22.40 23.70 21.80 23.56 0.06 -0.22 40.00 0.16 0.00 -0.05 47.75 122 27 127592 22.60 24.10 21.40 23.54 0.12 -0.22 40.00 0.10 0.00 -0.06 29.83 104 45 127642 22.90 23.60 21.80 23.14 0.11 -0.22 40.00 0.11 0.00 0.02 34.44 109 40 127692 22.90 23.60 21.80 23.14 0.11 -0.22 40.00 0.11 0.00 0.00 34.44 109 40 127742 23.90 24.40 21.60 22.42 0.23 -0.23 40.00 0.00 0.00 -0.11 1.31 76 73 127792 25.30 26.30 22.40 23.03 0.29 -0.23 40.00 -0.06 0.00 -0.07 -19.11 55 94 127842 26.10 28.10 23.10 24.38 0.30 -0.21 40.00 -0.09 0.00 -0.03 -27.53 47 102 127892 27.50 28.20 24.00 23.30 0.35 -0.22 40.00 -0.13 0.00 -0.04 -38.19 36 113 127942 27.80 29.90 25.00 26.41 0.28 -0.18 40.00 -0.10 0.00 0.03 -29.64 45 104 127992 29.70 30.30 26.80 26.53 0.29 -0.18 40.00 -0.11 0.00 -0.01 -33.12 41 108 128042 30.60 31.30 26.40 23.89 0.42 -0.21 40.00 -0.21 0.00 -0.09 -61.54 13 127 128092 30.90 31.30 26.40 23.89 0.42 -0.21 40.00 -0.21 0.00 0.00 -61.54 13 127 128142 30.90 32.00 27.80 27.51 0.31 -0.17 40.00 -0.14 0.00 0.06 -43.04 31 118 128192 30.80 31.80 28.50 29.22 0.23 -0.14 40.00 -0.09 0.00 0.06 -25.89 49 100 128242 31.00 32.10 28.90 29.91 0.21 -0.13 40.00 -0.08 0.00 0.01 -22.63 52 97 128292 31.20 32.80 29.10 30.56 0.21 -0.13 40.00 -0.08 0.00 -0.01 -25.24 49 100 128342 31.20 32.90 29.50 31.40 0.17 -0.11 40.00 -0.06 0.00 0.03 -16.60 58 91 128392 31.90 34.60 29.90 32.45 0.20 -0.10 40.00 -0.10 0.00 -0.04 -29.79 45 104 128442 31.60 34.30 30.70 33.85 0.09 -0.08 40.00 -0.01 0.00 0.09 -2.40 72 77 128492 32.20 34.10 30.30 32.18 0.19 -0.10 40.00 -0.09 0.00 -0.08 -25.70 49 100 128542 32.20 34.10 30.30 32.18 0.19 -0.10 40.00 -0.09 0.00 0.00 -25.70 49 100 128592 32.20 34.80 30.50 33.21 0.17 -0.09 40.00 -0.08 0.00 0.01 -23.86 51 98 128642 32.70 34.60 30.50 32.02 0.22 -0.11 40.00 -0.11 0.00 -0.03 -34.08 40 109 128692 32.70 34.90 30.90 33.12 0.18 -0.09 40.00 -0.09 0.00 0.03 -26.50 48 101 128742 32.60 34.10 31.60 33.55 0.10 -0.09 40.00 -0.01 0.00 0.07 -4.20 70 79 128792 32.50 34.70 31.10 33.62 0.14 -0.09 40.00 -0.05 0.00 -0.04 -16.46 58 91 128842 32.40 34.60 31.80 34.40 0.06 -0.07 40.00 0.01 0.00 0.07 4.41 79 70 128892 32.70 34.70 30.90 32.93 0.18 -0.09 40.00 -0.09 0.00 -0.10 -25.74 49 100 128942 32.40 35.40 31.20 34.58 0.12 -0.07 40.00 -0.05 0.00 0.04 -14.33 60 89 128992 32.20 34.60 32.10 34.59 0.01 -0.07 40.00 0.06 0.00 0.11 18.62 93 56 129042 32.90 33.80 31.90 33.25 0.10 -0.09 40.00 -0.01 0.00 -0.07 -3.02 71 78 129092 32.00 34.20 31.50 34.06 0.05 -0.08 40.00 0.03 0.00 0.04 8.76 83 66 129142 31.50 33.60 31.90 33.51 -0.04 -0.09 40.00 0.13 0.00 0.10 37.95 112 37 129192 32.00 34.00 31.50 33.86 0.05 -0.08 40.00 0.03 0.00 -0.09 9.55 84 65 129242 31.80 34.00 30.70 33.34 0.11 -0.09 40.00 -0.02 0.00 -0.05 -6.35 68 81 129292 31.90 34.30 30.80 33.63 0.11 -0.08 40.00 -0.03 0.00 -0.00 -7.53 67 82 129342 32.90 34.00 30.40 30.78 0.25 -0.12 40.00 -0.13 0.00 -0.10 -38.11 36 113 129392 32.40 34.70 30.30 32.33 0.21 -0.10 40.00 -0.11 0.00 0.02 -32.32 42 107 129442 33.30 34.90 31.00 32.07 0.23 -0.11 40.00 -0.12 0.00 -0.02 -37.28 37 112 129492 32.60 35.20 31.30 34.25 0.13 -0.08 40.00 -0.05 0.00 0.07 -15.99 59 90 129542 32.50 33.80 31.60 33.36 0.09 -0.09 40.00 -0.00 0.00 0.05 -0.43 74 75 129592 32.50 33.80 31.60 33.36 0.09 -0.09 40.00 -0.00 0.00 0.00 -0.43 74 75 129642 32.20 33.60 32.10 33.59 0.01 -0.09 40.00 0.08 0.00 0.08 22.62 97 52 129692 31.60 33.90 31.50 33.89 0.01 -0.08 40.00 0.07 0.00 -0.00 21.42 96 53 129742 30.90 33.30 30.80 33.29 0.01 -0.09 40.00 0.08 0.00 0.01 23.82 98 51 129792 30.50 33.00 29.70 32.66 0.08 -0.10 40.00 0.02 0.00 -0.06 5.37 80 69 129842 30.60 32.40 30.10 32.27 0.05 -0.10 40.00 0.05 0.00 0.04 15.93 90 59 129892 29.90 31.90 29.10 31.57 0.08 -0.11 40.00 0.03 0.00 -0.02 9.72 84 65 129942 29.90 31.30 28.20 29.87 0.17 -0.14 40.00 -0.03 0.00 -0.07 -10.50 64 85 129992 29.30 31.30 28.20 29.87 0.17 -0.14 40.00 -0.03 0.00 0.00 -10.50 64 85 130042 29.30 31.00 28.30 30.50 0.10 -0.13 40.00 0.03 0.00 0.06 8.00 83 66 130092 29.30 30.60 28.40 30.20 0.09 -0.13 40.00 0.04 0.00 0.01 12.20 87 62 130142 28.60 31.00 27.50 30.40 0.11 -0.13 40.00 0.02 0.00 -0.02 5.41 80 69 130192 28.30 30.00 27.50 29.69 0.08 -0.14 40.00 0.06 0.00 0.04 17.24 92 57 130242 27.20 29.80 26.60 29.63 0.06 -0.14 40.00 0.08 0.00 0.02 23.50 98 51 130292 27.20 27.90 26.60 27.74 0.06 -0.16 40.00 0.10 0.00 0.03 31.05 106 43 130342 27.10 28.10 26.00 27.55 0.11 -0.17 40.00 0.06 0.00 -0.05 16.79 91 58 130392 26.70 28.00 25.10 26.87 0.16 -0.18 40.00 0.02 0.00 -0.04 4.54 79 70 130442 26.10 27.90 25.30 27.61 0.08 -0.17 40.00 0.09 0.00 0.07 25.56 100 49 130492 25.60 27.20 24.30 26.46 0.13 -0.18 40.00 0.05 0.00 -0.03 15.14 90 59 130542 25.80 26.80 23.90 25.29 0.19 -0.20 40.00 0.01 0.00 -0.04 1.85 76 73 130592 24.80 27.20 24.00 26.92 0.08 -0.17 40.00 0.09 0.00 0.09 28.33 103 46 130642 24.70 25.80 24.10 25.65 0.06 -0.19 40.00 0.13 0.00 0.04 39.40 114 35 130692 25.00 26.20 23.00 24.57 0.20 -0.21 40.00 0.01 0.00 -0.13 1.72 76 73 130742 25.80 26.90 23.30 24.35 0.25 -0.21 40.00 -0.04 0.00 -0.05 -12.40 62 87 130792 32.20 29.80 23.40 10.19 0.88 -0.40 40.00 -0.48 0.00 -0.44 -144.74 0 127 |

Looking at the line at time 124142, we see:

|

1 2 |

Msec LF LC LR LCCorr Steer Tweak OffCm Err LastI LastD Out Lspd Rspd 124142 29.30 31.50 29.10 31.48 0.02 -0.11 40.00 0.09 0.00 0.06 28.08 103 46 |

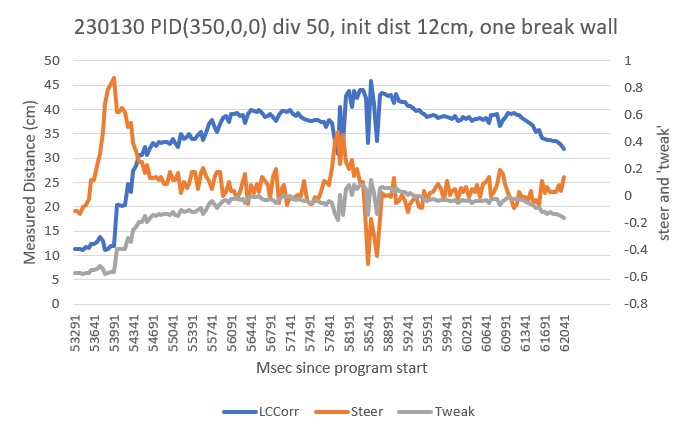

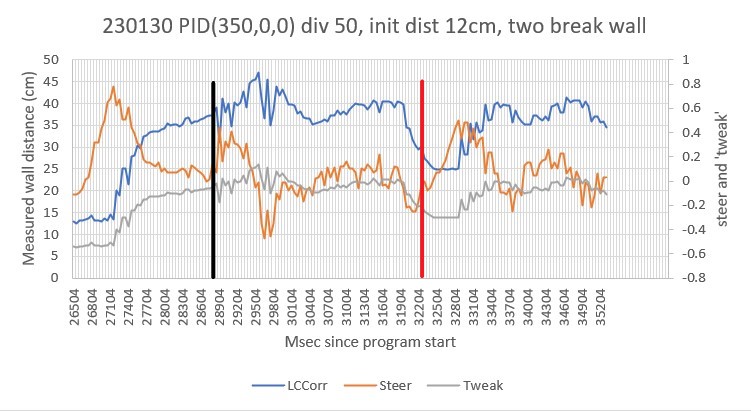

The steering value is very low (0.02) because the front and rear sensor distances are very close, but because the robot is well inside the intended offset distance of 40cm, the ‘tweak value’ of -0.11 is actually dominant, which drives the robot’s left motors harder than the right ones, which should correct the robot back toward 40cm offset. When we look at the Excel plot, we see:

The plot shows the ‘tweak’ value becoming more negative as the corrected distance becomes smaller relative to the desired offset distance of 40cm, and thus tends to correct the robot back toward the desired offset. At the 12.41sec mark (shown by the vertical line in the above plot) the ‘tweak’ value is -0.11, compared to the steering value of +0.02, so the ‘tweak’ input should dominate the output. With a P of 300, the output with just the steering value would be -300 x 0.02 = -6 resulting in left/right motor speeds of 69/81, steering the robot very slightly toward the wall. However, with the ‘tweak’ value of -0.02 the output is -300 x (0.02 -0.11) = +27 (actually +28), resulting in motor speeds of 103/46, or moderately away from the wall, as desired.

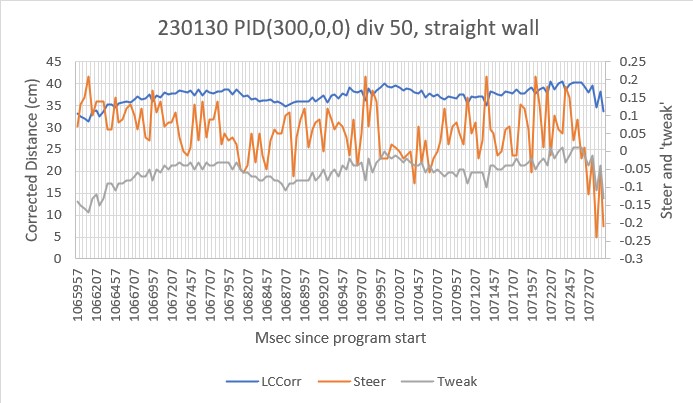

To simply the tuning problem, I changed the wall configuration back to a single straight wall, but started the robot with a 30cm offset (10cm closer than desired) but still parallel (steering value near zero). Here’s the output:

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 |