/*

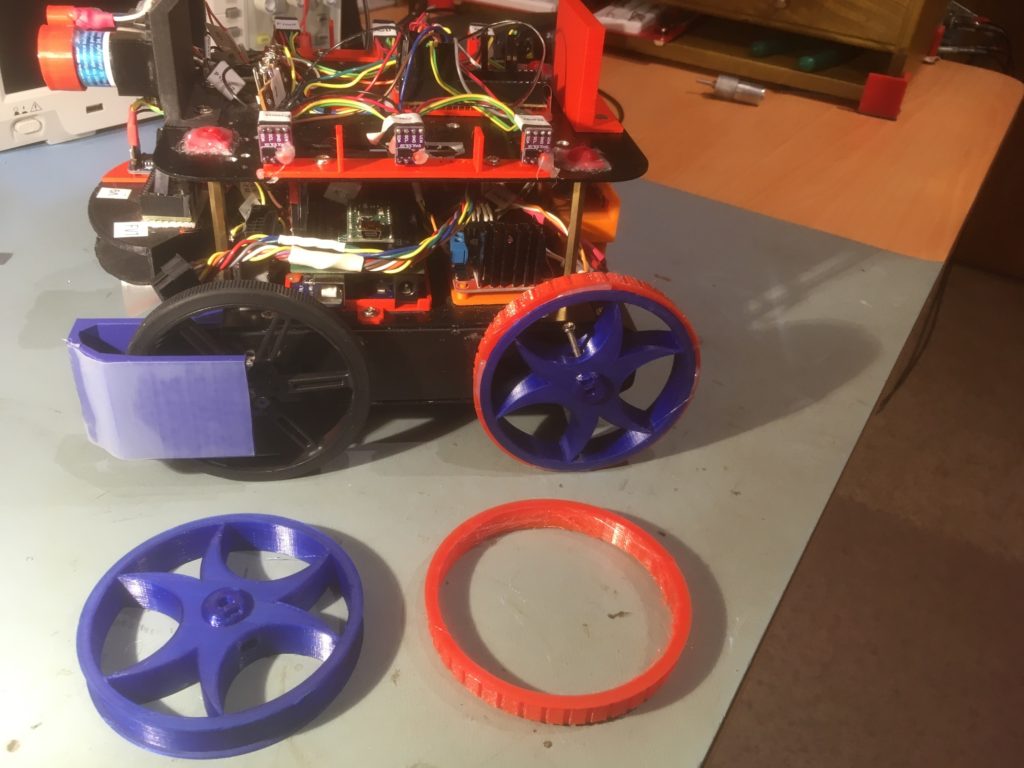

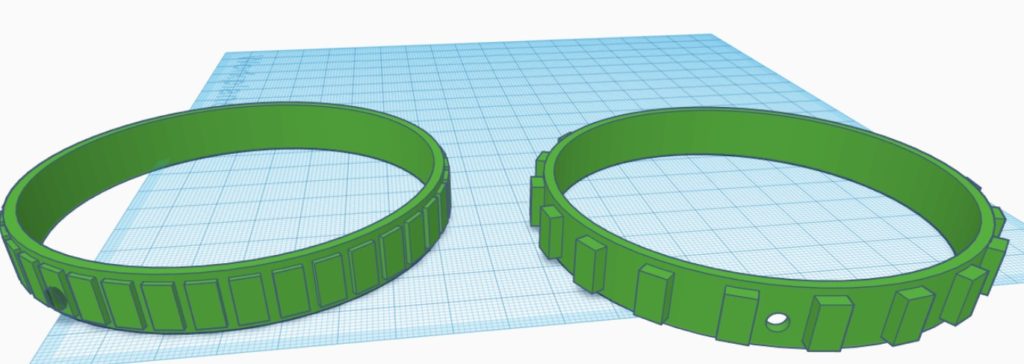

The wheel is defined as having a hub, a rim, and a tire. Wheel dimensions are overall diameter

and width, i.e. a 100mm x 30mm wheel will be a cylindrical shape with an overall diameter of 100mm

and a height (width) of 30mm. The rim will be a hollow cylinder with ID = overall diam - tire

thickness - rim thickness, and OD = ID + rim thickness. The cylindrical area between the center of

the wheel and the ID of the rim may be solid or spoked, and there may or may not be a hub.

*/

$fn=150;

wheelDiameter = 90; //overall diameter of the wheel, including rim & tire

wheelWidth = 15; //overall width (height) of the wheel, including guardrails

rimThickness = 5; //rim thickness (part of overall tire diameter)

tireThickness = 5; //tire thickness (part of overall tire diameter)

guardrailThickness = 2; //doesn't add to overall tire diameter

guardrailWidth = 1; //included in overall tire width

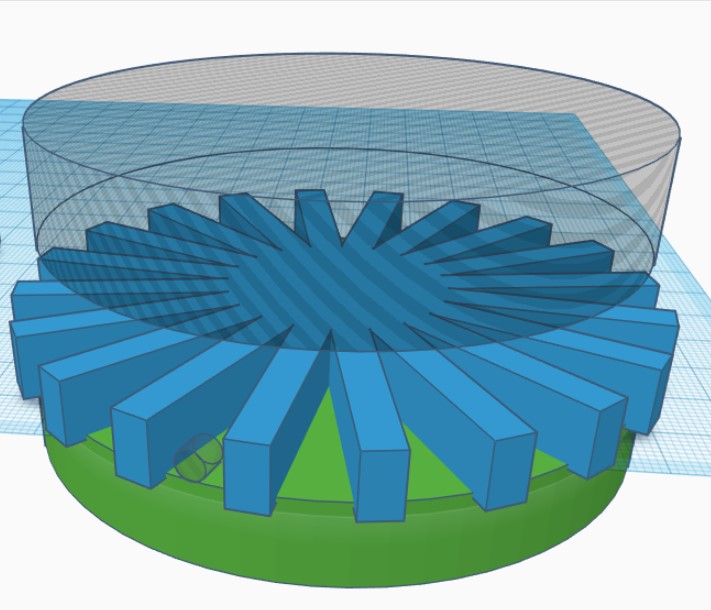

spokeThickness = 9;

numberOfSpokes = 3;

spokeEccentricity = 1.5; //how elliptical do the spokes look

//derived values

wheelMinusRimDiameter = wheelDiameter - rimThickness;

rimOD = wheelDiameter - tireThickness;

rimID = rimOD - rimThickness;

// The hub

includeHub = true; // Set to false to remove the hub and only include the shaft diameter hole.

hubDiameter = 15; // The diameter of the hub portion of the wheel

hubHeight = 18; // The total height of the hub

hubZOffset = -wheelWidth/2; // The Z position of the hub, negative numbers from the surface of the wheel

innerCircleDiameter = 0; // The diameter of the solid inner circle under the hub, or zero for none.

baseFilletRadius = 2; // The radius of the fillet (rounded part) between the hub and wheel.

topFilletRadius = 2; // The radius of the fillet (rounded part) at the top of the hub.

chamferOnly = false; // Set to true to use chamfers (straight 45-degree angles) instead of fillets.

concavity = [0,0];

//hardware

shaftDiameter = 4.5; // The diameter of the motor shaft

shaftFlatDiameter = 3.5 ; // The diameter of the motor shaft at the flat, or shaftDiameter for no flat.

setScrewCount = 1; // The number of set screws/nuts to render, spaced evenly around the shaft

setScrewDiameter = 3; // The diameter of the set screw. 3 is the default for an M3 screw.

setScrewTrap = [5.4, 2.3]; // Size [indiameter, thickness] of set screw nut. The depth is set automatically.

setScrewNutDiameter = 5.4; // The "diameter" of the captive nut, from flat to flat (the "in-diameter")

setScrewNutThickness = 2.3; // The thickness of the captive nut

setScrewNutOffset = 0; // The distance to offset the nut from the center of the material. -/+ = in/out

servoHoleDiameter = 0; // The diameter of servo arm hounting holes, or zero if no holes

servoHoleDistance1 = 25; // Distance across servo horn from hole to hole (0 to ignore)

servoHoleDistance2 = 21; // Distance across servo horn from hole to hole, rotated 90 degrees (0 to ignore)

servoArmRotation = 45; // The total rotation of all servo holes

servoNutTrap = [4,1.6]; // Size [indiameter, depth] of servo arm captive nut, or 0 (any) for none.

outerNutTrap = [12.5,0]; // Size [indiameter, depth] of a captive nut, or 0 (any) for none.

wheel_with_tire();

if ( includeHub )

{

translate([0,0, hubHeight/2 + wheelWidth/2 + hubZOffset - concavity[0]])

hub(hubHeight, hubDiameter, shaftDiameter, shaftFlatDiameter,

setScrewCount, setScrewTrap, setScrewDiameter, setScrewNutOffset,

hubZOffset, baseFilletRadius, topFilletRadius, chamferOnly);

}

/////////////////////////////////////////////////////////////////////////////

// Modules...

/////////////////////////////////////////////////////////////////////////////

// The hub (the part that holds the wheel onto the motor

module hub( height, diameter, shaftDiameter, shaftFlatDiameter, nuts, nutSize, setScrewDiameter,

setScrewNutOffset=0, hubZOffset=0, baseFilletRadius=0, topFilletRadius=0, chamferOnly=false) {

hubWidth=(diameter-shaftDiameter)/2;

union() {

difference() {

// Main hub shape

union() {

difference() {

union() {

cylinder( h=height, r=diameter/2, center=true );

// First chamfer the base...

translate([0,0,hubZOffset])

rotate_extrude()

translate([diameter/2,-(height/2)-hubZOffset,0])

polygon(points=[[0,0],[0,baseFilletRadius],[baseFilletRadius,0]]);

}

// Chamfer the top...

rotate_extrude()

translate([diameter/2,height/2,0])

polygon(points=[[0.5,0.5],[-topFilletRadius-0.5,0.5],[0.5, -topFilletRadius-0.5]]);

// Carve the bottom fillet from the chamfer

if ( !chamferOnly ) {

translate([0,0,hubZOffset])

rotate_extrude() {

translate([(diameter/2)+baseFilletRadius,

-(height-(2*baseFilletRadius))/2-hubZOffset,0]) {

circle(r=baseFilletRadius);

}

}

}

}

// Add the fillet back on top of the top chamfer

if (!chamferOnly) {

rotate_extrude() {

translate([

(diameter/2)-topFilletRadius,

(height-(2*topFilletRadius))/2,

0])

circle(r=topFilletRadius);

}

}

}

// Remove the bore

echo(str("shaftDiameter = ", shaftDiameter));

difference()

{

cylinder( h=height+1, r=shaftDiameter/2, center=true );

translate([(shaftDiameter-shaftFlatDiameter+1)/2 + (shaftDiameter/2)

- (shaftDiameter - shaftFlatDiameter),0,0])

cube( [shaftDiameter-shaftFlatDiameter+1,shaftDiameter,height+2], center=true );

}

// Remove the captive nut

//08/22/20 gfp bugfix: chg translate() z param to zero so it follows hub offsets

//08/22/20 gfp bugfix: repl 'boreDiameter' with 'shaftDiameter' to reduce confusion

for( i=[0:nuts-1] )

{

rotate([ 0,0, (360/nuts)*i ])

translate([shaftDiameter/2+(diameter-shaftDiameter)/4 +setScrewNutOffset,

0, 0])

{

rotate([0,-90,0])

{

captiveNut( nutSize, setScrewDiameter,

depth=height/2+1, holeLengthTop=hubWidth/2+setScrewNutOffset

+(shaftDiameter-shaftFlatDiameter),

holeLengthBottom=hubWidth+baseFilletRadius-setScrewNutOffset);

}

}

}

}

}

}

module wheel_with_tire()

{

difference()

{

union()

{

cylinder(wheelWidth, rimOD/2, rimOD/2, $fn=150);

cylinder(guardrailWidth,

guardrailThickness + rimOD/2,

guardrailThickness + rimOD/2,

$fn=150);

translate(v=[0,0,wheelWidth-guardrailWidth])

{

cylinder(guardrailWidth,

guardrailThickness + rimOD/2,

guardrailThickness + rimOD/2,

$fn=150);

}

}

translate(v=[0,0,-2])

{

cylinder(wheelWidth+4, rimID/2, rimID/2, $fn=150);

}

//08/22/20 remove setscrew access hole

//extend the hub shaft capture screw hole out past rim, so that

//it will pierce the rim if the hub sits low enough on the rim

if ( includeHub )

{

nutSize=setScrewTrap;

translate([0,0, hubHeight/2 + wheelWidth/2 + hubZOffset])

hubHoleCutout(hubHeight, hubDiameter, shaftDiameter, shaftFlatDiameter,

setScrewCount, setScrewTrap, setScrewDiameter, setScrewNutOffset,

hubZOffset, baseFilletRadius, topFilletRadius, chamferOnly);

}

}

if(numberOfSpokes > 0)

{

difference()

{

for (step = [0:numberOfSpokes-1])

{

rotate( [0, 0, step*(360/numberOfSpokes)] )

ellipticalSpoke(wheelWidth, wheelMinusRimDiameter, spokeEccentricity);

}

// Remove the motor shaft and setscrew nut trap cutouts if necessary

if(includeHub)

{

union()

{

//flatted motor shaft cutout

difference()

{

cylinder( h=(wheelWidth+hubHeight) + 2, r=shaftDiameter/2, center=true );

translate([(shaftDiameter-shaftFlatDiameter+1)/2 + (shaftDiameter/2)

- (shaftDiameter - shaftFlatDiameter),0,0])

cube( [shaftDiameter-shaftFlatDiameter+1,shaftDiameter,10*hubHeight+2], center=true );

}

//setscrew nut trap cutout

//08/22/20 gfp bugfix: chg translate() z param to zero so it follows hub offsets

//08/22/20 gfp bugfix: repl 'boreDiameter' with 'shaftDiameter' to reduce confusion

// for( i=[0:nuts-1] )

{

hubWidth=(hubDiameter-shaftDiameter)/2;

// rotate([ 0,0, (360/nuts)*i ])

// translate([shaftDiameter/2+(hubDiameter-shaftDiameter)/4 +setScrewNutOffset,

// 0, 0])

translate([shaftDiameter/2+(hubDiameter-shaftDiameter)/4 +setScrewNutOffset,0, hubHeight/2 + wheelWidth/2 + hubZOffset])

{

rotate([0,-90,0])

{

echo(str("captiveNut(",

setScrewTrap,

",",setScrewDiameter,

",",hubHeight/2+1,

",",hubWidth/2+setScrewNutOffset

+(shaftDiameter-shaftFlatDiameter),

",",hubWidth+baseFilletRadius-setScrewNutOffset,") call in spoke"));

captiveNut( setScrewTrap, setScrewDiameter,

depth=hubHeight/2+1, holeLengthTop=hubWidth/2+setScrewNutOffset

+(shaftDiameter-shaftFlatDiameter),

holeLengthBottom=hubWidth+baseFilletRadius-setScrewNutOffset);

}

}

}

}

}

//08/22/20 remove setscrew access hole

//extend the hub shaft capture screw hole out past rim, so that

//it will pierce the rim if the hub sits low enough on the rim

if ( includeHub )

{

hubWidth=(wheelDiameter-shaftDiameter)/2;

nutSize=setScrewTrap;

translate([0,0, hubHeight/2 + wheelWidth/2 + hubZOffset])

hubHoleCutout(hubHeight, hubDiameter, shaftDiameter, shaftFlatDiameter,

setScrewCount, setScrewTrap, setScrewDiameter, setScrewNutOffset,

hubZOffset, baseFilletRadius, topFilletRadius, chamferOnly);

}

}

}

}

module hubHoleCutout( height, diameter, boreDiameter, shaftFlatDiameter, nuts, nutSize, setScrewDiameter,

setScrewNutOffset=0, hubZOffset=0, baseFilletRadius=0, topFilletRadius=0, chamferOnly=false)

{

hubWidth=(diameter-boreDiameter)/2;

union()

{

// Remove the captive nut

for( i=[0:nuts-1] )

{

rotate([ 0,0, (360/nuts)*i ])

// translate([boreDiameter/2+(diameter-boreDiameter)/4 +setScrewNutOffset,

// 0, height/2 - (height+hubZOffset)/2])

translate([boreDiameter/2+(diameter-boreDiameter)/4 +setScrewNutOffset,

0,0])

{

rotate([0,-90,0])

{

echo(str("before call to captiveNutHoleExtension(",nutSize, ", ",setScrewDiameter, ", ",depth=height/2+1, ", ",hubWidth/2+setScrewNutOffset

+(boreDiameter-shaftFlatDiameter), ", ",hubWidth+baseFilletRadius-setScrewNutOffset));

//* captiveNut( nutSize, setScrewDiameter,

// depth=height/2+1, holeLengthTop=hubWidth/2+setScrewNutOffset

// +(boreDiameter-shaftFlatDiameter),

// holeLengthBottom=hubWidth+baseFilletRadius-setScrewNutOffset);

captiveNutHoleExtension( nutSize, setScrewDiameter,

depth=height/2+1, holeLengthTop=hubWidth/2+setScrewNutOffset

+(boreDiameter-shaftFlatDiameter),

holeLengthBottom=hubWidth+baseFilletRadius-setScrewNutOffset);

}

}

}

// }

}

}

module ellipticalSpoke(width, diameter, eccentricity)

{

translate([0,0,width/2])

intersection()

{

cylinder(h=width, r=wheelMinusRimDiameter/2, center = true);

translate([spokeEccentricity*wheelMinusRimDiameter/4, 0, 0])

scale([spokeEccentricity,1,1])

{

difference()

{

cylinder(h = width, r = wheelMinusRimDiameter/4, center = true);

//translation and width addition to make sure of good punch-out

translate([spokeThickness,0,0])

cylinder(h = width+4, r = wheelMinusRimDiameter/4, center = true);

}

}

}

}

//circleSpokes( d, wheelWidth, spokeThickness, proportion, numberOfSpokes );

//

//// Circles pattern spokes

//module circleSpokes( wheelDiameter, wheelWidth, spokeThickness, proportion, numberofSpokes ) {

// echo( "Circles Style..." );

// intersection() {

//# cylinder( h=wheelWidth, r=wheelDiameter/2, center = true );

//

// for (step = [0:numberofSpokes-1]) {

// rotate( [0, 0, step*(360/numberofSpokes)] )

// circleSpoke( wheelDiameter, wheelWidth, spokeThickness, proportion );

// }

// }

//

//}

//module circleSpoke( wheelDiameter, wheelWidth, spokeThickness, proportion ) {

//// render()

// echo(str("spokeThickness = ",spokeThickness));

// let( ox=(wheelDiameter/2)*proportion[0], oy=(wheelDiameter/2)*proportion[1] )

// let( ix=ox-(spokeThickness*2), iy=oy-(spokeThickness*2) )

// {

// translate ( [-ox/2, 0, 0] )

// {

// difference()

// {

// scale([proportion[0],proportion[1],1])

//# cylinder( r=wheelDiameter/4, h=wheelWidth, center=true);

// scale([(ix/ox)*proportion[0],(iy/oy)*proportion[1],1])

// cylinder( r=wheelDiameter/5, h=wheelWidth +1, center=true);

// }

// }

// }

//}

// This is the captive nut module I use in several of my designs.

module captiveNut( nutSize, setScrewHoleDiameter=3,

depth=10, holeLengthTop=5, holeLengthBottom=5 )

{

render()

union() {

nut( nutSize );

if ( depth > 0 )

translate([depth/2,0,0])

cube( [depth, nutSize[0], nutSize[1]], center=true );

translate([0,0,-(nutSize[1]/2)-holeLengthBottom])

cylinder(r=setScrewHoleDiameter/2, h=nutSize[1]+holeLengthTop+holeLengthBottom, $fn=15);

}

}

// nutSize = [inDiameter,thickness]

module nut( nutSize ) {

side = nutSize[0] * tan( 180/6 );

if ( nutSize[0] * nutSize[1] != 0 ) {

for ( i = [0 : 2] ) {

rotate( i*120, [0, 0, 1])

cube( [side, nutSize[0], nutSize[1]], center=true );

}

}

}

// This extends the captive nut hole so through the wheel rim for tool access

module captiveNutHoleExtension( nutSize, setScrewHoleDiameter=3,

depth=10, holeLengthTop=5, holeLengthBottom=5 )

{

translate([0,0,-wheelDiameter/2])

cylinder(r=1+setScrewDiameter/2, h=wheelDiameter/2, $fn=15);

}