// Implementation of Sebastian Madgwick's "...efficient orientation filter for... inertial/magnetic sensor arrays"

// (see http://www.x-io.co.uk/category/open-source/ for examples and more details)

// which fuses acceleration and rotation rate to produce a quaternion-based estimate of relative

// device orientation -- which can be converted to yaw, pitch, and roll. Useful for stabilizing quadcopters, etc.

// The performance of the orientation filter is at least as good as conventional Kalman-based filtering algorithms

// but is much less computationally intensive---it can be performed on a 3.3 V Pro Mini operating at 8 MHz!

void Class_MPU9250BasicAHRS::MadgwickQuaternionUpdate(float ax, float ay, float az, float gx, float gy, float gz)

//void Class_MPU9250BasicAHRS::MadgwickQuaternionUpdate(float ax, float ay, float az, float gx, float gy, float gz, float q_array[4], float delta_t)

{

float q1 = q[0], q2 = q[1], q3 = q[2], q4 = q[3]; // short name local variable for readability

//float q1 = q_array[0], q2 = q_array[1], q3 = q_array[2], q4 = q_array[3]; // short name local variable for readability

float norm; // vector norm

float f1, f2, f3; // objetive funcyion elements

float J_11or24, J_12or23, J_13or22, J_14or21, J_32, J_33; // objective function Jacobian elements

float qDot1, qDot2, qDot3, qDot4;

float hatDot1, hatDot2, hatDot3, hatDot4;

float gerrx, gerry, gerrz, gbiasx, gbiasy, gbiasz; // gyro bias error

// Auxiliary variables to avoid repeated arithmetic

float _halfq1 = 0.5f * q1;

float _halfq2 = 0.5f * q2;

float _halfq3 = 0.5f * q3;

float _halfq4 = 0.5f * q4;

float _2q1 = 2.0f * q1;

float _2q2 = 2.0f * q2;

float _2q3 = 2.0f * q3;

float _2q4 = 2.0f * q4;

//04/24/18 bugfix: these vars aren't used in 6DOF version

//float _2q1q3 = 2.0f * q1 * q3;

//float _2q3q4 = 2.0f * q3 * q4;

// Normalise accelerometer measurement

norm = sqrt(ax * ax + ay * ay + az * az);

if (norm == 0.0f) return; // handle NaN

norm = 1.0f / norm;

ax *= norm;

ay *= norm;

az *= norm;

// Compute the objective function and Jacobian

f1 = _2q2 * q4 - _2q1 * q3 - ax;

f2 = _2q1 * q2 + _2q3 * q4 - ay;

f3 = 1.0f - _2q2 * q2 - _2q3 * q3 - az;

J_11or24 = _2q3;

J_12or23 = _2q4;

J_13or22 = _2q1;

J_14or21 = _2q2;

J_32 = 2.0f * J_14or21;

J_33 = 2.0f * J_11or24;

// Compute the gradient (matrix multiplication)

hatDot1 = J_14or21 * f2 - J_11or24 * f1;

hatDot2 = J_12or23 * f1 + J_13or22 * f2 - J_32 * f3;

hatDot3 = J_12or23 * f2 - J_33 * f3 - J_13or22 * f1;

hatDot4 = J_14or21 * f1 + J_11or24 * f2;

// Normalize the gradient

norm = sqrt(hatDot1 * hatDot1 + hatDot2 * hatDot2 + hatDot3 * hatDot3 + hatDot4 * hatDot4);

hatDot1 /= norm;

hatDot2 /= norm;

hatDot3 /= norm;

hatDot4 /= norm;

// Compute estimated gyroscope biases

gerrx = _2q1 * hatDot2 - _2q2 * hatDot1 - _2q3 * hatDot4 + _2q4 * hatDot3;

gerry = _2q1 * hatDot3 + _2q2 * hatDot4 - _2q3 * hatDot1 - _2q4 * hatDot2;

gerrz = _2q1 * hatDot4 - _2q2 * hatDot3 + _2q3 * hatDot2 - _2q4 * hatDot1;

// Compute and remove gyroscope biases

//04/24/18 bugfix: gbias vars are unitialized here

//gbiasx += gerrx * deltat_sec * zeta;

//gbiasy += gerry * deltat_sec * zeta;

//gbiasz += gerrz * deltat_sec * zeta;

gbiasx = gerrx * deltat_sec * zeta;

gbiasy = gerry * deltat_sec * zeta;

gbiasz = gerrz * deltat_sec * zeta;

gx -= gbiasx;

gy -= gbiasy;

gz -= gbiasz;

// Compute the quaternion derivative

qDot1 = -_halfq2 * gx - _halfq3 * gy - _halfq4 * gz;

qDot2 = _halfq1 * gx + _halfq3 * gz - _halfq4 * gy;

qDot3 = _halfq1 * gy - _halfq2 * gz + _halfq4 * gx;

qDot4 = _halfq1 * gz + _halfq2 * gy - _halfq3 * gx;

// Compute then integrate estimated quaternion derivative

q1 += (qDot1 - (beta * hatDot1)) * deltat_sec;

q2 += (qDot2 - (beta * hatDot2)) * deltat_sec;

q3 += (qDot3 - (beta * hatDot3)) * deltat_sec;

q4 += (qDot4 - (beta * hatDot4)) * deltat_sec;

// Normalize the quaternion

norm = sqrt(q1 * q1 + q2 * q2 + q3 * q3 + q4 * q4); // normalise quaternion

norm = 1.0f / norm;

q[0] = q1 * norm;

q[1] = q2 * norm;

q[2] = q3 * norm;

q[3] = q4 * norm;

}

float Class_MPU9250BasicAHRS::GetIMUHeadingDeg()

{

// If intPin goes high, all data registers have new data

//if (readByte(MPU9250_ADDRESS, INT_STATUS) & 0x01)

{ // On interrupt, check if data ready interrupt

readAccelData(accelCount); // Read the x/y/z adc values

getAres();

// Now we'll calculate the accleration value into actual g's

ax = (float)accelCount[0] * aRes; // - accelBias[0]; // get actual g value, this depends on scale being set

ay = (float)accelCount[1] * aRes; // - accelBias[1];

az = (float)accelCount[2] * aRes; // - accelBias[2];

readGyroData(gyroCount); // Read the x/y/z adc values

getGres();

// Calculate the gyro value into actual degrees per second

gx = (float)gyroCount[0] * gRes; // get actual gyro value, this depends on scale being set

gy = (float)gyroCount[1] * gRes;

gz = (float)gyroCount[2] * gRes;

#ifndef NO_MAG

readMagData(magCount); // Read the x/y/z adc values

getMres();

magbias[0] = +470.; // User environmental x-axis correction in milliGauss, should be automatically calculated

magbias[1] = +120.; // User environmental x-axis correction in milliGauss

magbias[2] = +125.; // User environmental x-axis correction in milliGauss

// Calculate the magnetometer values in milliGauss

// Include factory calibration per data sheet and user environmental corrections

mx = (float)magCount[0] * mRes*magCalibration[0] - magbias[0]; // get actual magnetometer value, this depends on scale being set

my = (float)magCount[1] * mRes*magCalibration[1] - magbias[1];

mz = (float)magCount[2] * mRes*magCalibration[2] - magbias[2];

#endif // !NO_MAG

}

Now = micros();

deltat_sec = ((Now - lastUpdate) / 1000000.0f); // set integration time by time elapsed since last filter update

lastUpdate = Now;

sum += deltat_sec; // sum for averaging filter update rate

sumCount++;

// Sensors x (y)-axis of the accelerometer is aligned with the y (x)-axis of the magnetometer;

// the magnetometer z-axis (+ down) is opposite to z-axis (+ up) of accelerometer and gyro!

// We have to make some allowance for this orientationmismatch in feeding the output to the quaternion filter.

// For the MPU-9250, we have chosen a magnetic rotation that keeps the sensor forward along the x-axis just like

// in the LSM9DS0 sensor. This rotation can be modified to allow any convenient orientation convention.

// This is ok by aircraft orientation standards!

// Pass gyro rate as rad/s

#ifndef NO_MAG

MadgwickQuaternionUpdate(ax, ay, az, gx*PI / 180.0f, gy*PI / 180.0f, gz*PI / 180.0f, my, mx, mz);

// MahonyQuaternionUpdate(ax, ay, az, gx*PI/180.0f, gy*PI/180.0f, gz*PI/180.0f, my, mx, mz);

#else

//Serial.printf("q = {%4.2f, %4.2f, %4.2f, %4.2f, deltat_ms = %2.4f\n", q[0], q[1], q[2], q[3], deltat_sec*1000);

//experiment with multiple iterations on quat update

//for (size_t i = 0; i < 10; i++)

{

MadgwickQuaternionUpdate(ax, ay, az, gx*PI / 180.0f, gy*PI / 180.0f, gz*PI / 180.0f);

}

//MadgwickQuaternionUpdate(ax, ay, az, gx*PI / 180.0f, gy*PI / 180.0f, gz*PI / 180.0f, q, deltat_sec);

#endif // !NO_MAG

if (!AHRS)

{

delt_t = millis() - count;

if (delt_t > 500)

{

if (SerialDebug) {

// Print acceleration values in milligs!

Serial.print("X-acceleration: "); Serial.print(1000 * ax); Serial.print(" mg ");

Serial.print("Y-acceleration: "); Serial.print(1000 * ay); Serial.print(" mg ");

Serial.print("Z-acceleration: "); Serial.print(1000 * az); Serial.println(" mg ");

// Print gyro values in degree/sec

Serial.print("X-gyro rate: "); Serial.print(gx, 3); Serial.print(" degrees/sec ");

Serial.print("Y-gyro rate: "); Serial.print(gy, 3); Serial.print(" degrees/sec ");

Serial.print("Z-gyro rate: "); Serial.print(gz, 3); Serial.println(" degrees/sec");

#ifndef NO_MAG

// Print mag values in degree/sec

Serial.print("X-mag field: "); Serial.print(mx); Serial.print(" mG ");

Serial.print("Y-mag field: "); Serial.print(my); Serial.print(" mG ");

Serial.print("Z-mag field: "); Serial.print(mz); Serial.println(" mG");

tempCount = readTempData(); // Read the adc values

temperature = ((float)tempCount) / 333.87 + 21.0; // Temperature in degrees Centigrade

// Print temperature in degrees Centigrade

Serial.print("Temperature is "); Serial.print(temperature, 1); Serial.println(" degrees C"); // Print T values to tenths of s degree C

#endif // !NO_MAG

}

count = millis();

}

}

else

{

// Serial print and/or display at 0.5 s rate independent of data rates

delt_t = millis() - count;

//if (delt_t > 500)

{ // update LCD once per half-second independent of read rate

if (SerialDebug) {

Serial.print("ax = "); Serial.print((int)1000 * ax);

Serial.print(" ay = "); Serial.print((int)1000 * ay);

Serial.print(" az = "); Serial.print((int)1000 * az); Serial.println(" mg");

Serial.print("gx = "); Serial.print(gx, 2);

Serial.print(" gy = "); Serial.print(gy, 2);

Serial.print(" gz = "); Serial.print(gz, 2); Serial.println(" deg/s");

#ifndef NO_MAG

Serial.print("mx = "); Serial.print((int)mx);

Serial.print(" my = "); Serial.print((int)my);

Serial.print(" mz = "); Serial.print((int)mz); Serial.println(" mG");

#endif // !NO_MAG

Serial.print("q0 = "); Serial.print(q[0]);

Serial.print(" qx = "); Serial.print(q[1]);

Serial.print(" qy = "); Serial.print(q[2]);

Serial.print(" qz = "); Serial.println(q[3]);

}

// Define output variables from updated quaternion---these are Tait-Bryan angles, commonly used in aircraft orientation.

// In this coordinate system, the positive z-axis is down toward Earth.

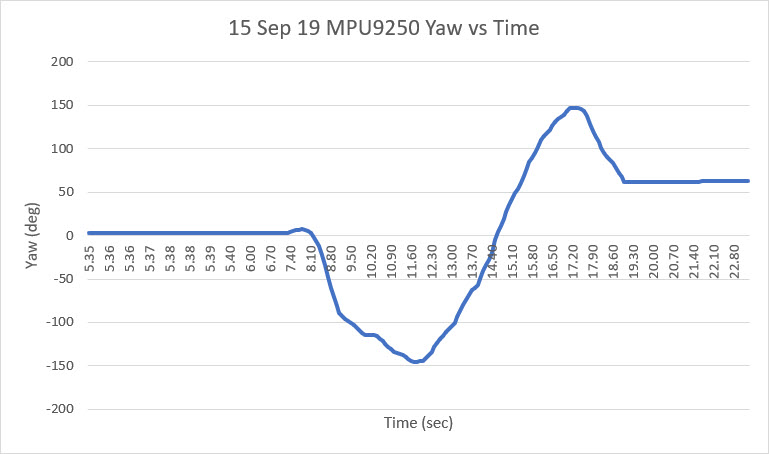

// Yaw is the angle between Sensor x-axis and Earth magnetic North (or true North if corrected for local declination, looking down on the sensor positive yaw is counterclockwise.

// Pitch is angle between sensor x-axis and Earth ground plane, toward the Earth is positive, up toward the sky is negative.

// Roll is angle between sensor y-axis and Earth ground plane, y-axis up is positive roll.

// These arise from the definition of the homogeneous rotation matrix constructed from quaternions.

// Tait-Bryan angles as well as Euler angles are non-commutative; that is, the get the correct orientation the rotations must be

// applied in the correct order which for this configuration is yaw, pitch, and then roll.

// For more see http://en.wikipedia.org/wiki/Conversion_between_quaternions_and_Euler_angles which has additional links.

yaw = atan2(2.0f * (q[1] * q[2] + q[0] * q[3]), q[0] * q[0] + q[1] * q[1] - q[2] * q[2] - q[3] * q[3]);

pitch = -asin(2.0f * (q[1] * q[3] - q[0] * q[2]));

roll = atan2(2.0f * (q[0] * q[1] + q[2] * q[3]), q[0] * q[0] - q[1] * q[1] - q[2] * q[2] + q[3] * q[3]);

pitch *= 180.0f / PI;

yaw *= 180.0f / PI;

//yaw -= 13.8; // Declination at Danville, California is 13 degrees 48 minutes and 47 seconds on 2014-04-04

roll *= 180.0f / PI;

if (SerialDebug) {

Serial.print("Yaw, Pitch, Roll: ");

Serial.print(yaw, 2);

Serial.print(", ");

Serial.print(pitch, 2);

Serial.print(", ");

Serial.println(roll, 2);

Serial.print("rate = "); Serial.print((float)sumCount / sum, 2); Serial.println(" Hz");

}

//Serial.printf("%3.2f\t%3.2f\t%3.2f\n", yaw, pitch, roll);

// With these settings the filter is updating at a ~145 Hz rate using the Madgwick scheme and

// >200 Hz using the Mahony scheme even though the display refreshes at only 2 Hz.

// The filter update rate is determined mostly by the mathematical steps in the respective algorithms,

// the processor speed (8 MHz for the 3.3V Pro Mini), and the magnetometer ODR:

// an ODR of 10 Hz for the magnetometer produce the above rates, maximum magnetometer ODR of 100 Hz produces

// filter update rates of 36 - 145 and ~38 Hz for the Madgwick and Mahony schemes, respectively.

// This is presumably because the magnetometer read takes longer than the gyro or accelerometer reads.

// This filter update rate should be fast enough to maintain accurate platform orientation for

// stabilization control of a fast-moving robot or quadcopter. Compare to the update rate of 200 Hz

// produced by the on-board Digital Motion Processor of Invensense's MPU6050 6 DoF and MPU9150 9DoF sensors.

// The 3.3 V 8 MHz Pro Mini is doing pretty well!

digitalWrite(myLed, !digitalRead(myLed));

count = millis();

sumCount = 0;

sum = 0;

}

}

return yaw;

}